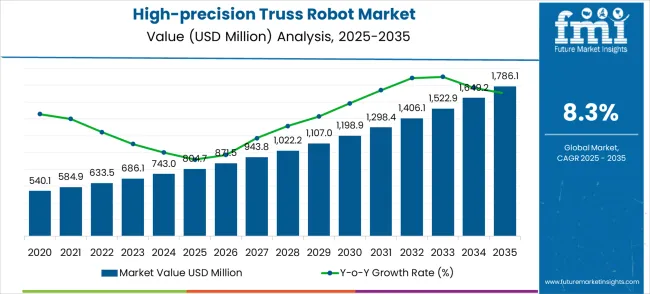

The high-precision truss robot market is projected to expand from USD 804.7 million in 2025 to USD 1,786.1 million by 2035, reflecting a robust forecast CAGR of 8.3%. This growth trajectory highlights the increasing adoption of automated and precise handling systems across industrial, construction, and entertainment sectors. Year-on-year expansion is supported by rising demand for high-accuracy positioning, repeatable motion control, and integration into complex assembly lines and large-scale event staging. The market growth is expected to be driven by incremental deployment in robotic automation projects where operational efficiency and precision are critical. Manufacturing facilities and event production companies are increasingly favoring high-precision truss robots for tasks requiring synchronized movement, load management, and enhanced safety, reinforcing the market’s upward trajectory. The combination of versatility and accuracy positions these robots as essential components for modern industrial and large-scale logistical applications.

Yearly projections indicate that the market is expected to reach USD 871.5 million in 2026, USD 943.8 million in 2027, and USD 1,022.2 million in 2028, ultimately reaching USD 1,786.1 million by 2035. The steady growth pattern reflects a balanced adoption rate, influenced by capital expenditure in automated solutions and the demand for precision robotics across multiple sectors. The market demonstrates a consistent increase in value due to the ability of high-precision truss robots to enhance operational efficiency, reduce manual labor, and improve safety standards. Industrial automation, stage production, and large-scale logistics are expected to remain primary end-use areas driving growth. The rising preference for reliable and programmable robotic systems ensures the market maintains a strong, long-term upward trend. Overall, the high-precision truss robot market is positioned as a strategic investment area, showing sustained adoption across sectors where accuracy, load handling, and repeatable operations are prioritized.

| High-precision Truss Robot Market | Value |

|---|---|

| Market Value (2025) | USD 804.7 million |

| Market Forecast Value (2035) | USD 1,786.1 million |

| Market Forecast CAGR | 8.3% |

The high-precision truss robot market holds a significant position within the industrial robots market, contributing around 14% of the share, as these robots are increasingly adopted for complex manufacturing tasks requiring high accuracy. Within the automation equipment market, it accounts for about 10%, reflecting its role in streamlining production processes and improving operational efficiency. In the manufacturing robotics market, the market share is estimated at 12%, driven by the demand for precise, flexible automation solutions across industries. The robotics for electronics assembly market sees approximately 8% share, highlighting applications in circuit board assembly and electronic component handling. Finally, within the precision machinery market, the high-precision truss robot market holds around 6%, emphasizing its importance in high-accuracy manufacturing environments. These combined contributions underline its critical role across multiple precision-driven industries.

Market expansion is being supported by the rapid increase in specialized precision manufacturing worldwide and the corresponding need for ultra-high accuracy equipment that provides superior precision performance and operational reliability for advanced manufacturing processes requiring exceptional tolerances. Modern precision manufacturing facilities rely on consistent ultra-accuracy performance and stringent quality control to ensure optimal production precision including aerospace manufacturing, electronics assembly, and medical device production facilities. Even microscopic precision variations can require comprehensive process adjustments to maintain optimal manufacturing standards and ultra-precision performance.

The growing complexity of precision manufacturing automation requirements and increasing demand for ultra-high accuracy assembly solutions are driving demand for high-precision truss robots from certified manufacturers with appropriate ultra-precision capabilities and specialized automation expertise. Precision manufacturing companies are increasingly requiring documented accuracy specifications and ultra-reliability standards to maintain production quality and operational precision. Industry specifications and precision standards are establishing standardized ultra-accuracy procedures that require specialized high-precision robotic technologies and trained precision automation personnel.

The High-precision Truss Robot market is entering a new phase of growth, driven by demand for ultra-precision automation, specialized manufacturing expansion, and evolving accuracy and efficiency standards. By 2035, these pathways together can unlock USD 350-450 million in incremental revenue opportunities beyond baseline growth.

Pathway A -- Advanced Configuration Leadership (Five & Six-Axis Systems) The five-axis segment already holds the largest share due to its superior precision and complexity capabilities. Expanding ultra-precision optimization, control enhancement, and specialized accuracy features can consolidate leadership. Opportunity pool: USD 100-140 million.

Pathway B -- Specialized Precision Applications (Aerospace & Electronics) Automobile manufacturing accounts for the largest demand, but aerospace and electronics represent high-growth precision sectors. Growing specialized manufacturing will drive higher adoption of ultra-precision robots. Opportunity pool: USD 80-110 million.

Pathway C -- Ultra-High Precision Configurations (Six-Axis & Advanced Systems) The most sophisticated systems are expanding with increasing focus on ultra-precision manufacturing. Robots designed for exceptional accuracy operations can capture significant premium growth. Opportunity pool: USD 60-80 million.

Pathway D -- Emerging Precision Market Expansion Asia-Pacific and Latin America present growing demand due to rising precision manufacturing infrastructure. Targeting specialized networks and ultra-accuracy solutions will accelerate adoption. Opportunity pool: USD 40-60 million.

Pathway E -- AI-Enhanced Precision & Smart Manufacturing With increasing digitalization, there is an opportunity to promote AI-enabled and IoT-connected ultra-precision robotic systems for intelligent manufacturing. Opportunity pool: USD 30-40 million.

Pathway F -- Premium Precision Industry Applications Systems optimized for medical devices, semiconductor manufacturing, and ultra-precision research offer premium positioning for specialized high-accuracy facilities. Opportunity pool: USD 20-30 million.

Pathway G -- Precision Service & Calibration Support Recurring revenue from precision maintenance services, accuracy calibration, and ultra-precision system upgrades creates long-term revenue streams. Opportunity pool: USD 15-25 million.

Pathway H -- Digital Precision Integration & Predictive Analytics Digital accuracy monitoring, predictive precision maintenance, and ultra-accuracy analytics can elevate robots into "smart precision" equipment categories. Opportunity pool: USD 10-15 million.

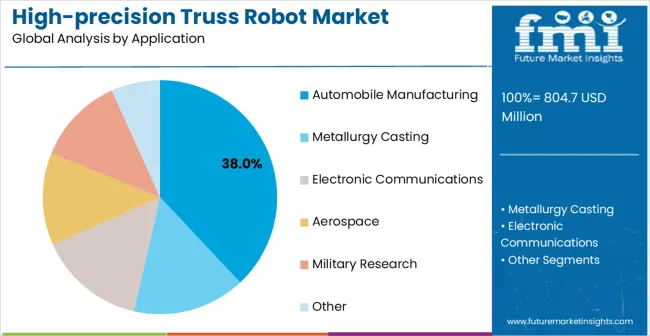

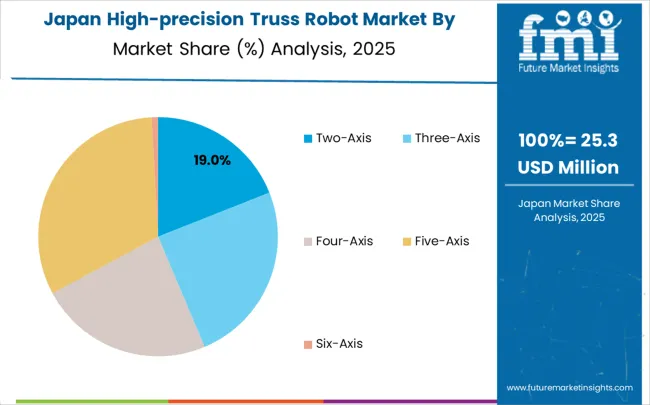

The market is segmented by axis configuration, application, and region. By axis configuration, the market is divided into two-axis, three-axis, four-axis, five-axis, six-axis, and other configurations. Based on application, the market is categorized into automobile manufacturing, metallurgy casting, electronic communications, aerospace, and military research. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

In 2025, the five-axis high-precision truss robot segment is projected to capture around 32% of the total market share, making it the leading configuration category. This dominance is largely driven by the widespread adoption of advanced precision systems that provide optimal balance between operational sophistication and ultra-accuracy capability, catering to a wide variety of specialized precision manufacturing applications. The five-axis configuration is particularly favored for its ability to deliver exceptional precision performance in both complex and ultra-demanding assembly operations, ensuring manufacturing excellence and accuracy reliability. Aerospace manufacturers, precision electronics producers, medical device manufacturing facilities, and ultra-precision assembly complexes increasingly prefer this configuration, as it meets stringent accuracy requirements without imposing excessive system complexity or programming difficulties.

The availability of well-established precision product lines, along with comprehensive accuracy calibration options and specialized technical support from leading manufacturers, further reinforces the segment's market position. Additionally, this configuration category benefits from consistent demand across regions, as it is considered a reliable and ultra-precise solution for facilities requiring advanced accuracy systems and operational precision excellence. The combination of ultra-precision, operational flexibility, and specialized accuracy makes five-axis high-precision truss robots a dependable choice, ensuring their continued popularity in the specialized automation and precision manufacturing equipment markets.

The automobile manufacturing segment is expected to represent 38% of high-precision truss robot demand in 2025, highlighting its position as the most significant application sector. This dominance stems from the critical precision requirements of advanced automotive production environments, where ultra-high accuracy assembly and consistent precision quality are essential to premium vehicle manufacturing standards and production excellence. Advanced automobile manufacturing often features ultra-complex precision assembly processes that demand specialized high-accuracy automation equipment throughout extensive production lines, requiring reliable and ultra-precise robotic solutions. High-precision truss robots are particularly well-suited to these environments due to their ability to provide consistent ultra-accuracy performance and operational reliability, even during high-volume precision production conditions.

As premium automotive industries expand globally and emphasize improved manufacturing precision, the demand for high-precision truss robots continues to rise. The segment also benefits from heightened accuracy standards within the automotive industry, where manufacturers are increasingly prioritizing ultra-precision automation and production consistency as essential manufacturing measures for premium vehicles. With automotive companies investing in advanced precision manufacturing technologies and specialized accuracy standards, high-precision truss robots provide an essential solution to maintain ultra-performance vehicle production. The growth of electric and luxury vehicle manufacturing, coupled with increased focus on precision automation standards, ensures that automobile manufacturing will remain the largest and most stable demand driver for high-precision truss robots in the forecast period.

The High-precision Truss Robot market is advancing rapidly due to increasing specialized precision manufacturing development and growing recognition of ultra-high accuracy robotic automation advantages over standard precision systems in critical manufacturing applications. However, the market faces challenges including significantly higher investment costs compared to standard automation solutions, need for specialized ultra-precision programming and maintenance expertise, and complex integration requirements with existing manufacturing systems across different precision industrial environments. Ultra-precision optimization efforts and advanced artificial intelligence integration programs continue to influence equipment development and market adoption patterns.

The growing development of advanced ultra-precision control systems and specialized artificial intelligence integration is enabling exceptional accuracy levels with improved operational efficiency and enhanced ultra-precision capabilities. Advanced control technologies and optimized ultra-precision algorithms provide superior manufacturing accuracy while maintaining operational flexibility requirements for specialized applications. These technologies are particularly valuable for precision manufacturing operators who require reliable ultra-accuracy performance that can support extensive precision production operations with consistent ultra-precision results.

Modern high-precision truss robot manufacturers are incorporating advanced specialized precision capabilities and intelligent ultra-accuracy monitoring systems that enhance operational efficiency and manufacturing precision effectiveness. Integration of predictive precision maintenance systems and optimized ultra-accuracy data analytics enables superior production optimization and comprehensive precision manufacturing intelligence capabilities. Advanced ultra-precision features support operation in diverse specialized manufacturing environments while meeting various ultra-accuracy requirements and precision automation specifications.

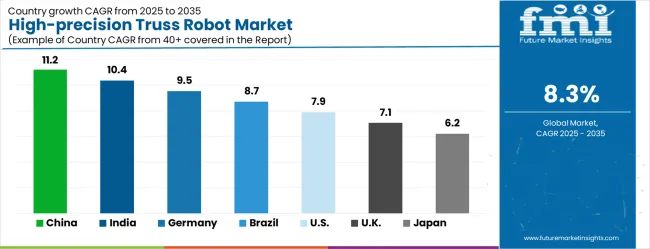

| Country | CAGR (2025-2035) |

|---|---|

| China | 11.2% |

| India | 10.4% |

| Germany | 9.5% |

| Brazil | 8.7% |

| United States | 7.9% |

| United Kingdom | 7.1% |

| Japan | 6.2% |

The high-precision truss robot market is growing rapidly, with China leading at an 11.2% CAGR through 2035, driven by massive precision manufacturing development and increasing adoption of ultra-high accuracy technologies. India follows at 10.4%, supported by rising specialized manufacturing infrastructure development and growing awareness of precision automation benefits. Germany grows strongly at 9.5%, integrating advanced ultra-precision robotics into its established precision manufacturing infrastructure. Brazil records 8.7%, emphasizing precision industrial modernization and ultra-accuracy upgrade initiatives. The United States shows solid growth at 7.9%, focusing on specialized manufacturing efficiency enhancement and precision optimization. The United Kingdom demonstrates steady progress at 7.1%, maintaining established precision automation applications. Japan records 6.2% growth, concentrating on ultra-precision advancement and specialized accuracy applications.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

The high-precision truss robot market in China is projected to exhibit the highest growth rate with a CAGR of 11.2% through 2035, driven by unprecedented expansion of precision manufacturing infrastructure and increasing demand for ultra-high accuracy industrial robotics. The country's massive specialized manufacturing sector and expanding precision automotive production facilities are creating enormous demand for ultra-precision automation solutions. Major precision manufacturers are establishing comprehensive ultra-accuracy robotics integration networks to support the increasing requirements of specialized industrial companies and precision manufacturing facilities across production regions.

Government precision manufacturing development initiatives are supporting establishment of ultra-precision manufacturing facilities and specialized production complexes, driving demand for advanced ultra-accuracy robotics throughout major precision industrial zones. Specialized manufacturing sector modernization programs are facilitating adoption of intelligent ultra-precision automation technologies that enhance production accuracy and specialized quality standards across precision industrial networks.

The high-precision truss robot market in India is expanding at a CAGR of 10.4%, supported by increasing precision manufacturing sector development and growing awareness of ultra-high accuracy automation benefits. The country's expanding specialized automotive and precision electronics manufacturing infrastructure and rising ultra-precision quality standards are driving demand for advanced ultra-accuracy robotics solutions. Precision manufacturing companies and specialized industrial facilities are gradually implementing ultra-precision automation equipment to maintain competitive accuracy standards and operational precision excellence.

Precision industrial sector growth and specialized manufacturing infrastructure development are creating opportunities for suppliers that can support diverse ultra-accuracy requirements and precision specifications. Professional training and specialized technical programs are building expertise among precision manufacturing personnel, enabling effective utilization of high-precision robot technology that meets ultra-accuracy automation standards and specialized production requirements.

The high-precision truss robot market in Germany is projected to grow at a CAGR of 9.5%, supported by the country's emphasis on specialized precision standards and ultra-advanced manufacturing technology adoption. German precision manufacturing facilities are implementing sophisticated ultra-accuracy automation systems that meet stringent precision requirements and specialized operational specifications. The market is characterized by focus on ultra-precision technological excellence, specialized manufacturing accuracy, and compliance with comprehensive ultra-precision automation standards.

Precision manufacturing industry investments are prioritizing cutting-edge ultra-accuracy automation technology that demonstrates superior precision performance and reliability while meeting German specialized quality and efficiency standards. Professional certification programs are ensuring comprehensive technical expertise among ultra-precision automation personnel, enabling specialized ultra-accuracy robotics capabilities that support diverse precision manufacturing applications and facility requirements.

The high-precision truss robot market in Brazil is growing at a CAGR of 8.7%, driven by increasing precision industrial facility development and growing recognition of ultra-high accuracy automation technology advantages. The country's expanding specialized automotive and precision manufacturing sectors are gradually integrating advanced ultra-accuracy robotics to enhance production precision and specialized quality standards. Precision industrial facilities and specialized manufacturing plants are investing in ultra-precision automation technology to address evolving accuracy requirements and competitive pressures in specialized markets.

Precision industrial facility modernization is facilitating adoption of advanced ultra-accuracy automation technologies that support comprehensive specialized manufacturing capabilities across precision industrial regions. Professional development programs are enhancing technical capabilities among precision manufacturing personnel, enabling effective high-precision robot utilization that meets evolving specialized industrial standards and ultra-precision production requirements.

The high-precision truss robot market in the USA is expanding at a CAGR of 7.9%, driven by established precision manufacturing industries and growing emphasis on specialized production efficiency enhancement. Large precision manufacturing companies and specialized industrial automation providers are implementing comprehensive ultra-accuracy robotics capabilities to serve diverse specialized production requirements. The market benefits from established precision automation distribution networks and professional development programs that support various specialized manufacturing applications.

Precision manufacturing industry leadership is enabling standardized ultra-accuracy robotics utilization across multiple specialized production types, providing consistent precision standards and comprehensive ultra-accuracy coverage throughout regional markets. Professional development and certification programs are building specialized technical expertise among precision manufacturing personnel, enabling effective high-precision robot utilization that supports evolving specialized industrial facility requirements.

The high-precision truss robot market in the UK is projected to grow at a CAGR of 7.1%, supported by established precision manufacturing sectors and growing emphasis on ultra-accuracy efficiency capabilities. British precision manufacturing facilities and specialized industrial service providers are implementing ultra-accuracy robotics systems that meet industry precision standards and specialized operational requirements. The market benefits from established precision manufacturing infrastructure and comprehensive training programs for specialized automation professionals.

Precision manufacturing facility investments are prioritizing advanced ultra-accuracy robotics that support diverse specialized production applications while maintaining established precision and quality standards. Professional development programs are building technical expertise among precision manufacturing personnel, enabling specialized high-precision robot operation capabilities that meet evolving facility requirements and ultra-accuracy standards.

The high-precision truss robot market in Japan is growing at a CAGR of 6.2%, driven by the country's focus on ultra-precision manufacturing technology innovation and specialized accuracy enhancement applications. Japanese precision manufacturing facilities are implementing advanced ultra-accuracy robotics systems that demonstrate superior precision reliability and operational consistency for specialized applications. The market is characterized by emphasis on ultra-precision technological excellence, specialized quality assurance, and integration with established precision manufacturing workflows.

Precision manufacturing technology investments are prioritizing innovative ultra-accuracy automation solutions that combine advanced high-precision robotics with specialized engineering while maintaining Japanese ultra-precision quality and reliability standards. Professional development programs are ensuring comprehensive technical expertise among precision manufacturing personnel, enabling specialized ultra-accuracy capabilities that support diverse precision industrial applications and facility requirements.

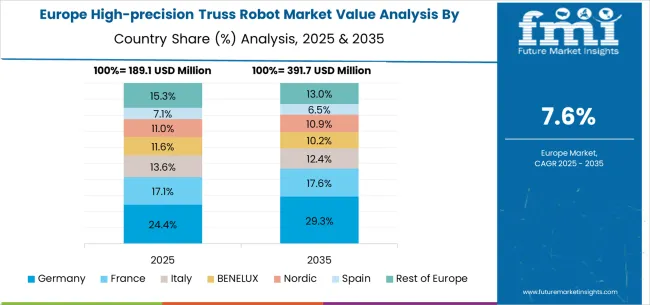

The high-precision truss robot market in Europe is forecast to expand from USD 210.1 million in 2025 to USD 466.4 million by 2035, registering a CAGR of 8.2%. Germany will remain the largest market, holding 32.8% share in 2025, easing to 32.1% by 2035, supported by strong precision manufacturing infrastructure and ultra-advanced accuracy automation standards. The United Kingdom follows, rising from 21.5% in 2025 to 22.0% by 2035, driven by specialized precision facility modernization and ultra-accuracy enhancement initiatives. France is expected to maintain stability from 16.2% to 15.9%, reflecting consistent precision manufacturing industry investments and specialized accuracy requirements. Italy holds around 12.8% throughout the forecast period, supported by precision manufacturing facility upgrades and ultra-accuracy system modernization programs. Spain grows from 9.1% to 9.7% with expanding precision manufacturing infrastructure and increased focus on specialized ultra-accuracy solutions. BENELUX markets maintain 4.3% to 4.1%, while the remainder of Europe hovers near 3.3%--3.4%, balancing emerging Eastern European precision manufacturing development against mature Nordic markets with established ultra-precision technology adoption patterns.

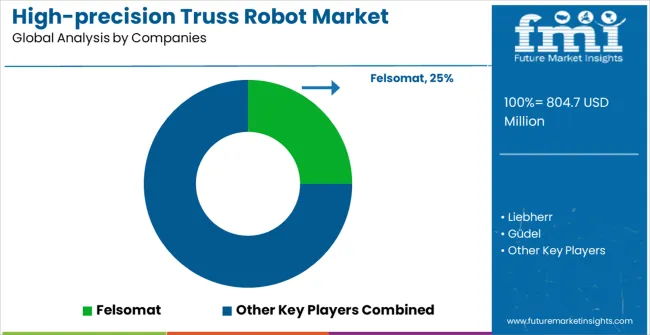

The High-precision Truss Robot market is defined by competition among specialized ultra-precision robotics manufacturers, advanced industrial automation companies, and specialized precision manufacturing solution providers. Companies are investing in cutting-edge ultra-accuracy control technology development, precision optimization, advanced artificial intelligence integration, and comprehensive specialized automation service capabilities to deliver reliable, ultra-precise, and cost-effective specialized manufacturing solutions. Strategic partnerships, ultra-precision technological innovation, and specialized manufacturing expertise are central to strengthening product portfolios and market presence.

Felsomat offers comprehensive ultra-precision automation solutions with established specialized robotics expertise and professional-grade precision manufacturing capabilities. Liebherr provides specialized ultra-accuracy industrial equipment with focus on precision reliability and specialized operational performance. Güdel delivers advanced ultra-precision automation systems with emphasis on specialized manufacturing efficiency and accuracy-friendly operation. FLT Automation GmbH specializes in ultra-precision robotics with advanced control technology integration for specialized applications.

FANUC offers professional-grade ultra-precision industrial robotics with comprehensive specialized technical support capabilities. SIASUN Robot & Automation delivers established ultra-accuracy automation solutions with advanced multi-axis precision technologies. Qingdao Kingerobot provides specialized ultra-precision robotics equipment with focus on accuracy optimization for specialized applications. Lecn, Anhui Hengtong Group, STON Robot, Wuxi Xinjinyu Intelligent Manufacturing, Zhejiang Yili Robot Technology, Jiangsu Hanfeng CNC Technology, Welllih Robot, Suzhou De'ao Automation Technology, and Kunfeng Cranes offer specialized ultra-precision manufacturing expertise, product reliability, and comprehensive development across global and regional specialized automation market segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 804.7 million |

| Axis Configuration | Two-Axis, Three-Axis, Four-Axis, Five-Axis, Six-Axis |

| Application | Automobile Manufacturing, Metallurgy Casting, Electronic Communications, Aerospace, Military Research, and Other |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Felsomat, Liebherr, Güdel, FLT Automation GmbH, FANUC, SIASUN Robot & Automation, Qingdao Kingerobot, Lecn, Anhui Hengtong Group, STON Robot, Wuxi Xinjinyu Intelligent Manufacturing, Zhejiang Yili Robot Technology, Jiangsu Hanfeng CNC Technology, Welllih Robot, Suzhou De'ao Automation Technology, Kunfeng Cranes |

| Additional Attributes | Dollar sales by axis configuration and application segment, regional demand trends across major markets, competitive landscape with established ultra-precision robotics manufacturers and emerging specialized automation providers, customer preferences for different axis configurations and ultra-precision options, integration with specialized manufacturing systems and precision automation protocols, innovations in ultra-accuracy control technology and precision enhancement, and adoption of advanced precision features with enhanced ultra-accuracy capabilities for improved specialized manufacturing workflows. |

The global high-precision truss robot market is estimated to be valued at USD 804.7 million in 2025.

The market size for the high-precision truss robot market is projected to reach USD 1,786.1 million by 2035.

The high-precision truss robot market is expected to grow at a 8.3% CAGR between 2025 and 2035.

The key product types in high-precision truss robot market are two-axis, three-axis, four-axis, five-axis and six-axis.

In terms of application, automobile manufacturing segment to command 38.0% share in the high-precision truss robot market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Multi-axis Truss Robot Market Size and Share Forecast Outlook 2025 to 2035

Robot Controller, Integrator and Software Market Size and Share Forecast Outlook 2025 to 2035

Robotic Warfare Market Size and Share Forecast Outlook 2025 to 2035

Robotic Lawn Mower Market Size and Share Forecast Outlook 2025 to 2035

Robotics Welding Market Size and Share Forecast Outlook 2025 to 2035

Robotic Rehab Tools Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Robotics-Assisted Telesurgery Market Size and Share Forecast Outlook 2025 to 2035

Robotic Packaging Machines Market Size and Share Forecast Outlook 2025 to 2035

Robot Assisted Surgical Microscope Market Size and Share Forecast Outlook 2025 to 2035

Robotic Assisted Endovascular Systems Market Size and Share Forecast Outlook 2025 to 2035

Robotic Lung Biopsy Market Size and Share Forecast Outlook 2025 to 2035

Robotics as a Service (RaaS) Market Size and Share Forecast Outlook 2025 to 2035

Robotic X-ray Scanner Market Size and Share Forecast Outlook 2025 to 2035

Robotic Catheterization Systems Market Growth – Innovations, Trends & Forecast 2025-2035

Robot Sensor Market Size and Share Forecast Outlook 2025 to 2035

Robotaxi Market Size and Share Forecast Outlook 2025 to 2035

Robotic Aseptic Syringe Filler Capper Market Size and Share Forecast Outlook 2025 to 2035

Robot Market Size and Share Forecast Outlook 2025 to 2035

Robotic Vision Market Size and Share Forecast Outlook 2025 to 2035

Robotics Actuators Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA