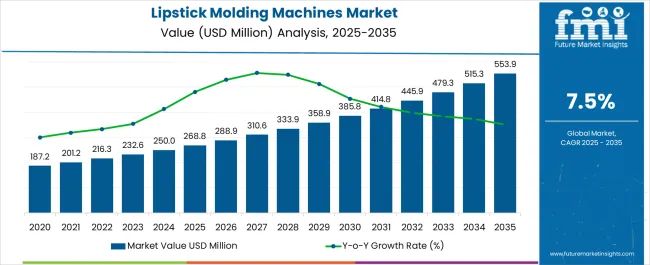

The Lipstick Molding Machines Market is estimated to be valued at USD 268.8 million in 2025 and is projected to reach USD 553.9 million by 2035, registering a compound annual growth rate (CAGR) of 7.5% over the forecast period.

| Metric | Value |

|---|---|

| Lipstick Molding Machines Market Estimated Value in (2025 E) | USD 268.8 million |

| Lipstick Molding Machines Market Forecast Value in (2035 F) | USD 553.9 million |

| Forecast CAGR (2025 to 2035) | 7.5% |

The Lipstick Molding Machines market is expanding steadily, supported by the growing global demand for cosmetics and the rising popularity of premium and customized lip products. Increasing consumer interest in diverse shades, textures, and finishes has pushed manufacturers to adopt advanced machinery that ensures precision and efficiency in lipstick production. Automation, digital control, and enhanced mold technologies are helping cosmetic companies improve production speed, reduce wastage, and maintain consistency in quality.

The growing focus on sustainability is also driving demand for machines that optimize raw material usage and support eco-friendly packaging processes. Rising investments in R&D for developing versatile lipstick formulations have created the need for molding machines capable of accommodating complex shapes and innovative finishes. Emerging markets, particularly in Asia Pacific, are witnessing rapid growth due to increasing disposable income and evolving beauty standards.

Moreover, the influence of e-commerce, celebrity endorsements, and social media-driven trends is shaping product innovation and fueling production scale-up With ongoing technological advancements and heightened consumer demand, the Lipstick Molding Machines market is positioned for long-term growth across both developed and developing regions.

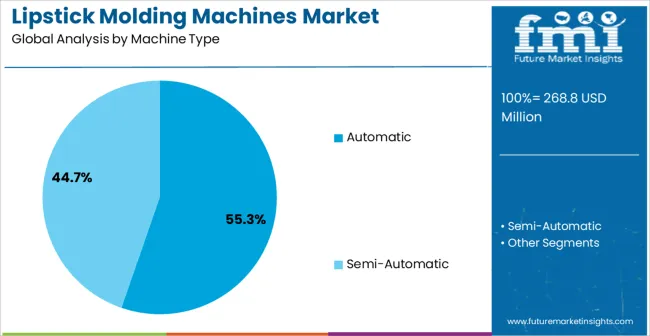

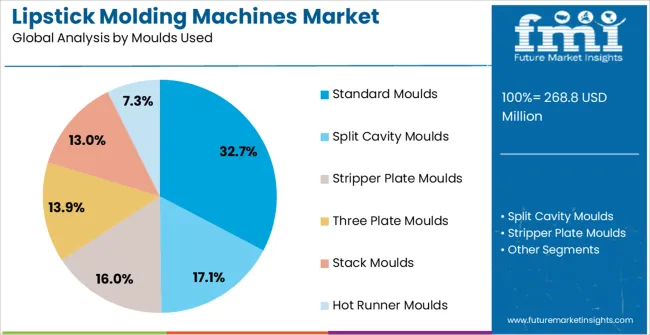

The lipstick molding machines market is segmented by machine type, moulds used, and geographic regions. By machine type, lipstick molding machines market is divided into Automatic and Semi-Automatic. In terms of moulds used, lipstick molding machines market is classified into Standard Moulds, Split Cavity Moulds, Stripper Plate Moulds, Three Plate Moulds, Stack Moulds, and Hot Runner Moulds. Regionally, the lipstick molding machines industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The automatic machine type segment is projected to account for 55.3% of the Lipstick Molding Machines market revenue share in 2025, making it the dominant segment. Its leadership stems from the efficiency, precision, and consistency offered by automatic systems, which reduce dependency on manual labor while ensuring uniform quality across large production batches. These machines are increasingly favored by leading cosmetic manufacturers, as they support higher output rates and minimize production downtime through advanced automation features.

Integrated digital controls, automated temperature management, and real-time monitoring capabilities allow manufacturers to achieve accuracy in molding complex lipstick designs while reducing operational errors. Furthermore, automatic machines contribute to cost savings in the long term by optimizing resource use and minimizing product defects.

Their scalability and compatibility with modern production lines also support the industry’s shift toward large-scale, high-speed manufacturing As demand for innovative lipstick varieties grows, the automatic segment is expected to maintain dominance, driven by its ability to balance productivity, efficiency, and precision in a competitive market landscape.

The standard moulds segment is anticipated to hold 32.7% of the Lipstick Molding Machines market revenue share in 2025, positioning it as the leading mould type. Growth in this segment is driven by its widespread adoption among manufacturers for producing conventional lipstick designs that remain highly popular with consumers globally. Standard moulds are preferred for their durability, cost-effectiveness, and ease of integration into existing production systems.

Their ability to support high-volume manufacturing while maintaining consistent quality makes them ideal for mass-market lipstick production. Additionally, manufacturers benefit from reduced maintenance costs and simplified operations compared to customized moulds, making standard moulds a practical choice for established product lines. While premium and niche brands experiment with unique shapes and finishes, mainstream cosmetic producers continue to rely on standard moulds for efficiency and broad consumer appeal.

Their proven compatibility with both semi-automatic and automatic machines further strengthens adoption As demand for classic lipstick formats continues to remain robust worldwide, the standard moulds segment is expected to sustain its leadership role in the overall market.

Cosmetic packaging and machinery market is one of the fastest growing markets, and comprises of a large variety of products. Lipstick is one of the most enduring of cosmetic products. Lipstick molding machines are used for proper filling up of lipsticks under containers or tubes. Penetration of packaging in cosmetics is has increased at a meteoric pace, in the last few decades.

Lipstick is one of the most sought after cosmetic products, across the globe. Lipstick molding machines are useful in order to enhance the efficiency while reducing the time required for molding and packaging of the product. Over the years, many technological changes have taken place. Before filling lipstick under its container, it is moulded into a bullet shape.

Initially, molding equipment is used to be made up of steel or aluminium, and the process involved pouring the hot molten formula into the mould. The process for molding of lipstick was automated in 1971 when Peter Weckerle invented the first fully automatic lipstick molding machine.

Today, various types of lipstick molding machines are available in market, these are multipurpose, which means they are capable of changing moulds. So, the machine is not just used as a lipstick molding machine, but it can also be used for other cosmetic products, such as slim sticks, lip balms, and make-up sticks.

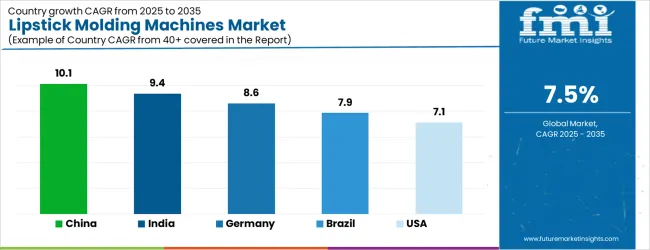

| Country | CAGR |

|---|---|

| China | 10.1% |

| India | 9.4% |

| Germany | 8.6% |

| Brazil | 7.9% |

| USA | 7.1% |

| UK | 6.4% |

| Japan | 5.6% |

The Lipstick Molding Machines Market is expected to register a CAGR of 7.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 10.1%, followed by India at 9.4%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.6%, yet still underscores a broadly positive trajectory for the global Lipstick Molding Machines Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 8.6%. The USA Lipstick Molding Machines Market is estimated to be valued at USD 99.8 million in 2025 and is anticipated to reach a valuation of USD 99.8 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 14.0 million and USD 8.7 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 268.8 Million |

| Machine Type | Automatic and Semi-Automatic |

| Moulds Used | Standard Moulds, Split Cavity Moulds, Stripper Plate Moulds, Three Plate Moulds, Stack Moulds, and Hot Runner Moulds |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

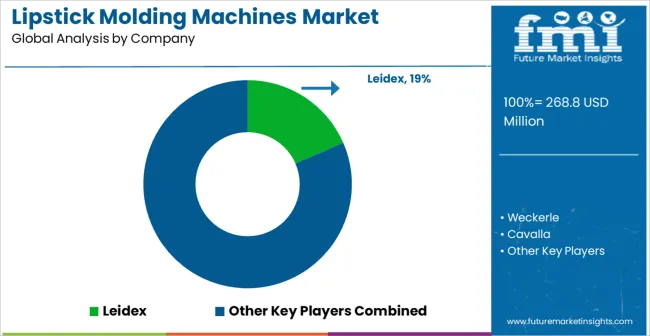

| Key Companies Profiled | Leidex, Weckerle, Cavalla, Zhengzhou Shaolin Mechanical & Electrical Equipment, Shanghai Biaozan Industrial, Guangzhou Kimyi Machinery, and Shantou Dachuan Machines |

The global lipstick molding machines market is estimated to be valued at USD 268.8 million in 2025.

The market size for the lipstick molding machines market is projected to reach USD 553.9 million by 2035.

The lipstick molding machines market is expected to grow at a 7.5% CAGR between 2025 and 2035.

The key product types in lipstick molding machines market are automatic and semi-automatic.

In terms of moulds used, standard moulds segment to command 32.7% share in the lipstick molding machines market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Pulp Molding Machines Market Size and Share Forecast Outlook 2025 to 2035

Injection Molding Machines Industry Analysis in India Size, Share & Forecast 2025 to 2035

Stretch Blow Molding Machines Market Segmentation based on Technology Type, Orientation Type, End Use, and Region: A Forecast for 2025 and 2035

Market Share Insights of Leading Stretch Blow Molding Machines Providers

Particle Foam Molding Machines Market Size and Share Forecast Outlook 2025 to 2035

PET Stretch Blow Molding Machines Market Size and Share Forecast Outlook 2025 to 2035

Europe Injection Molding Machines Market Size and Share Forecast Outlook 2025 to 2035

Key Companies & Market Share in PET Stretch Blow Molding Machines Sector

Sliding Injection Molding Machines Market Size and Share Forecast Outlook 2025 to 2035

Molding Starch Market Size and Share Forecast Outlook 2025 to 2035

Lipstick Market

Bulk Molding Compounds Market Size and Share Forecast Outlook 2025 to 2035

Pulp Molding Tooling Market Size and Share Forecast Outlook 2025 to 2035

Blow Molding Resin Market Growth – Trends & Forecast 2024-2034

Lathe Machines Market

Sorter Machines Market Size and Share Forecast Outlook 2025 to 2035

Rubber Molding Market Forecast Outlook 2025 to 2035

Custom Lipstick Shade Market Growth – Demand & Forecast 2024-2034

Virtual Machines Market by Type, by Enterprise Size, by Industry & Region Forecast till 2035

Bandsaw Machines Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA