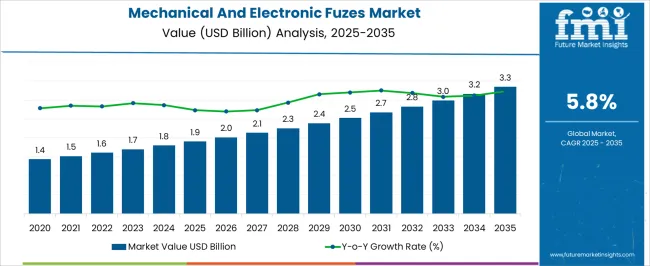

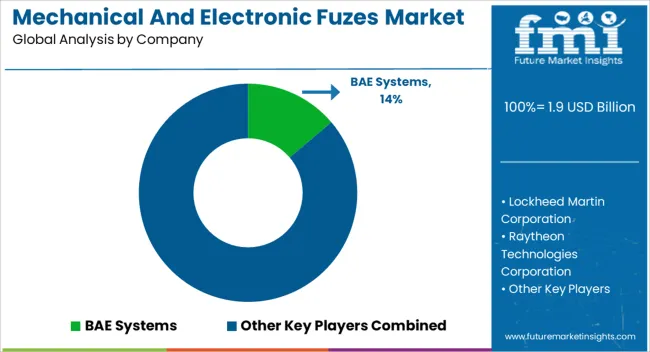

The Mechanical And Electronic Fuzes Market is estimated to be valued at USD 1.9 billion in 2025 and is projected to reach USD 3.3 billion by 2035, registering a compound annual growth rate (CAGR) of 5.8% over the forecast period.

| Metric | Value |

|---|---|

| Mechanical And Electronic Fuzes Market Estimated Value in (2025 E) | USD 1.9 billion |

| Mechanical And Electronic Fuzes Market Forecast Value in (2035 F) | USD 3.3 billion |

| Forecast CAGR (2025 to 2035) | 5.8% |

The Mechanical And Electronic Fuzes market is witnessing steady growth, driven by the increasing demand for precision, reliability, and safety in modern defense and military applications. Rising investments in artillery modernization programs, coupled with the need for enhanced accuracy and operational efficiency, are creating strong market opportunities. Technological advancements in fuze design, including electronic triggering, proximity sensing, and programmable functionalities, are improving performance while reducing misfire risks.

Growing adoption of smart munitions and guided weapons is further supporting market expansion. The integration of mechanical and electronic fuze systems into existing defense platforms allows for enhanced tactical flexibility, improved targeting accuracy, and better operational outcomes. As defense budgets increase globally and military organizations focus on modernization, demand for high-performance fuze systems is expected to rise.

Continuous innovation in materials, electronics, and miniaturization technologies is also shaping the market landscape The market is projected to maintain long-term growth, driven by a combination of strategic defense initiatives, advanced technology adoption, and rising operational demands.

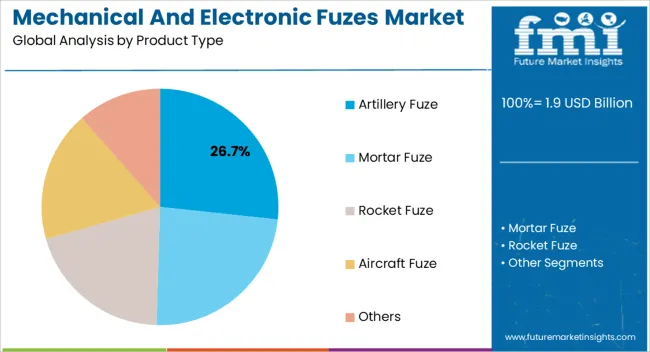

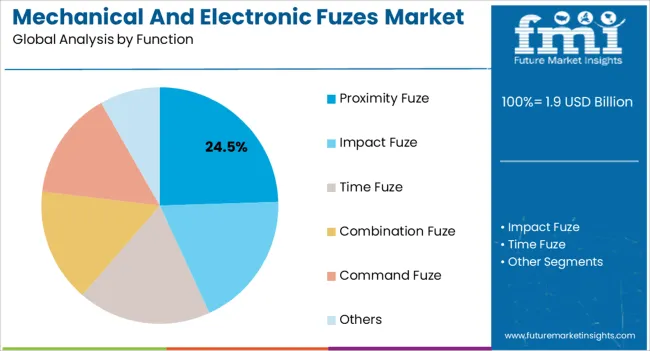

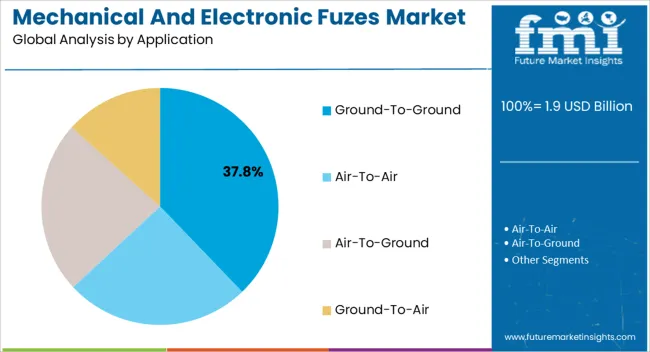

The mechanical and electronic fuzes market is segmented by product type, function, application, and geographic regions. By product type, mechanical and electronic fuzes market is divided into Artillery Fuze, Mortar Fuze, Rocket Fuze, Aircraft Fuze, and Others. In terms of function, mechanical and electronic fuzes market is classified into Proximity Fuze, Impact Fuze, Time Fuze, Combination Fuze, Command Fuze, and Others. Based on application, mechanical and electronic fuzes market is segmented into Ground-To-Ground, Air-To-Air, Air-To-Ground, and Ground-To-Air. Regionally, the mechanical and electronic fuzes industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The artillery fuze segment is projected to hold 26.7% of the market revenue in 2025, establishing it as the leading product type. Its dominance is being driven by the critical role it plays in enhancing the safety, accuracy, and effectiveness of artillery munitions. Mechanical and electronic fuze technologies allow for precise detonation timing, improved blast control, and reduced collateral damage, which is highly valued in operational deployment.

The segment benefits from increasing modernization programs across global defense forces and the growing adoption of precision-guided munitions. The ability to integrate with various artillery systems without significant modifications strengthens operational flexibility and reliability.

Innovations in electronic fuze miniaturization, programmable functionality, and environmental resilience further enhance performance and adoption As militaries continue to prioritize accuracy, operational efficiency, and compliance with safety standards, the artillery fuze segment is expected to maintain its market leadership, driven by both technological innovation and strategic defense procurement.

The proximity fuze function segment is anticipated to account for 24.5% of the market revenue in 2025, making it the leading function category. Its growth is being supported by the increasing need for precise target engagement and reduced collateral damage in modern warfare scenarios. Proximity fuze systems enable munitions to detonate near the target rather than on impact, enhancing effectiveness against moving or airborne threats.

Technological improvements in sensor accuracy, electronic triggering, and integration with guidance systems are further supporting adoption. Military forces are increasingly leveraging proximity fuze functionality in artillery shells, rockets, and other munitions to improve operational outcomes and mission success rates.

The ability to retrofit these systems into existing platforms without extensive modifications enhances their appeal With rising global defense spending, modernization of artillery systems, and the focus on precision-guided munitions, the proximity fuze segment is expected to remain the primary growth driver in fuze functions, supported by continued innovation and operational performance improvements.

The ground-to-ground application segment is projected to hold 37.8% of the market revenue in 2025, establishing it as the leading application category. Growth in this segment is being driven by the need for effective engagement in tactical ground combat operations, where accurate artillery and munitions deployment is critical. Mechanical and electronic fuze systems in ground-to-ground applications provide reliable detonation timing, reduced misfire rates, and optimized blast effects.

Adoption is further enhanced by the increasing modernization of land-based artillery, multiple launch rocket systems, and precision-guided munitions. The ability to integrate advanced fuze technologies with existing weapon systems without major structural modifications increases operational flexibility.

As defense organizations focus on reducing collateral damage, improving targeting accuracy, and enhancing overall battlefield effectiveness, demand for ground-to-ground applications is expected to remain strong Continuous innovation in electronic triggering, environmental resilience, and functional precision supports sustained growth in this leading application segment.

Missiles, rockets, bombs, shells and other ammunitions form a vital part of the firing capacity of a military in modern warfare. Since these ammunitions are loaded with explosives, there is always a risk of explosion during storage, launching and handling. This requires the incorporation of some security gadgets into these ammunitions.

The security system should work until the ammunition is propelled and after the launch, the firing mechanism should take control. In order to accomplish this, an arming mechanism is also required in the ammunition. All the above mentioned necessities are fulfilled by gadgets called fuzes.

Fuzes are electronic or mechanical devices attached to ammunition to provide reliable and safe detonations at the desired time and place. These devices control safe separation of ammunition from the delivery platform and trigger its detonation.

Basic functions of fuze are arming, safing, firing and target sensing. Mechanical fuzes have their safing, arming and firing mechanisms which mostly involves mechanical components, linkages and other mechanisms.

Due to their simplicity and ease of conceptualization, mechanical fuzes were the earliest fuzes developed and are still used for many different types of ammunitions. Fuzes operated by mechanical devices make use of mechanical linkages like gears, springs, rotors, sliders and plungers or a combination of some of these. As a result of extensive safety requirements, mechanical fuzes have many components and are of a clockwork design.

There are certain factors that are of primary concern while designing mechanical and electrical fuzes. These include safety and resistance, deterioration in use, handling and storage, reliability of action, simple construction and adequate strength.

As a result of extensive safety requirements, mechanical fuzes generally have many components and are of a clockwork design. The electronic fuzes were developed in mid1960’s and thereafter, there has been continuous development in this technology. Today, electronic fuzes are being used in many modern weapon systems and have replaced mechanical fuzes in many places.

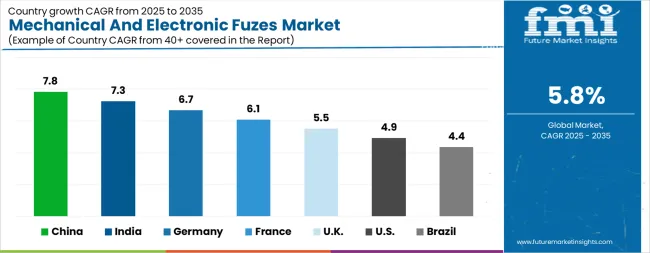

| Country | CAGR |

|---|---|

| China | 7.8% |

| India | 7.3% |

| Germany | 6.7% |

| France | 6.1% |

| UK | 5.5% |

| USA | 4.9% |

| Brazil | 4.4% |

The Mechanical And Electronic Fuzes Market is expected to register a CAGR of 5.8% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 7.8%, followed by India at 7.3%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 4.4%, yet still underscores a broadly positive trajectory for the global Mechanical And Electronic Fuzes Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 6.7%. The USA Mechanical And Electronic Fuzes Market is estimated to be valued at USD 705.6 million in 2025 and is anticipated to reach a valuation of USD 1.1 billion by 2035. Sales are projected to rise at a CAGR of 4.9% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 90.2 million and USD 48.8 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.9 Billion |

| Product Type | Artillery Fuze, Mortar Fuze, Rocket Fuze, Aircraft Fuze, and Others |

| Function | Proximity Fuze, Impact Fuze, Time Fuze, Combination Fuze, Command Fuze, and Others |

| Application | Ground-To-Ground, Air-To-Air, Air-To-Ground, and Ground-To-Air |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | BAE Systems, Lockheed Martin Corporation, Raytheon Technologies Corporation, Northrop Grumman Corporation, L3Harris Technologies, Inc., General Dynamics Corporation, Saab AB, Thales Group, Rheinmetall AG, Orbital ATK (Now Northrop Grumman Innovation Systems), Moog Inc., Kongsberg Gruppen, Diehl Defence GmbH & Co. KG, and Expal Systems |

The global mechanical and electronic fuzes market is estimated to be valued at USD 1.9 billion in 2025.

The market size for the mechanical and electronic fuzes market is projected to reach USD 3.3 billion by 2035.

The mechanical and electronic fuzes market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key product types in mechanical and electronic fuzes market are artillery fuze, mortar fuze, rocket fuze, aircraft fuze and others.

In terms of function, proximity fuze segment to command 24.5% share in the mechanical and electronic fuzes market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Mechanical Shaft Seal Market Size and Share Forecast Outlook 2025 to 2035

Mechanical Reciprocating Engine Market Size and Share Forecast Outlook 2025 to 2035

Mechanical Testing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Mechanical Locks Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Mechanical Coil Tester Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Mechanical Performance Tuning Components Market Growth - Trends & Forecast 2025 to 2035

Mechanical Ventilator Market - Demand & Growth Outlook 2025 to 2035

Mechanical Seals Market Growth - Trends & Forecast 2025 to 2035

Understanding Market Share Trends in the Mechanical Locks Industry

Mechanical Keyboard Market

Electromechanical Timers Market Size and Share Forecast Outlook 2025 to 2035

Bicycle Mechanical Disc Brake Market Size and Share Forecast Outlook 2025 to 2035

Dynamic Mechanical Analyzer Market

Chemical Mechanical Planarization Market Growth – Size & Forecast 2025 to 2035

5G Electromechanical RF Switch Market Size and Share Forecast Outlook 2025 to 2035

Nanoelectromechanical Systems (NEMS) Market - Trends & Forecast 2025 to 2035

Micro-electromechanical System (MEMS) Market Size and Share Forecast Outlook 2025 to 2035

Micro-Electro Mechanical Systems Market Size and Share Forecast Outlook 2025 to 2035

High Precision Mechanical Machine Components Market Size and Share Forecast Outlook 2025 to 2035

Android Automotive OS (AAOS) Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA