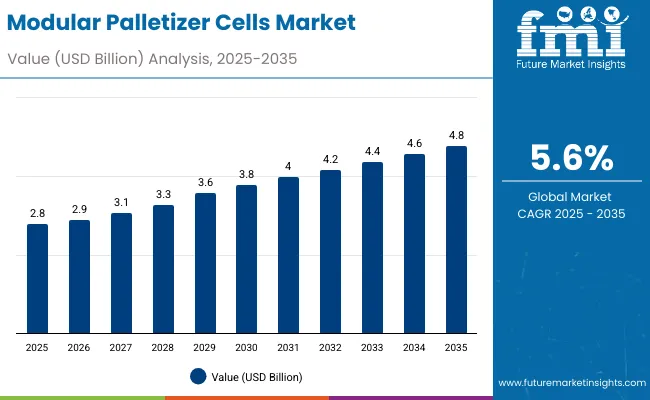

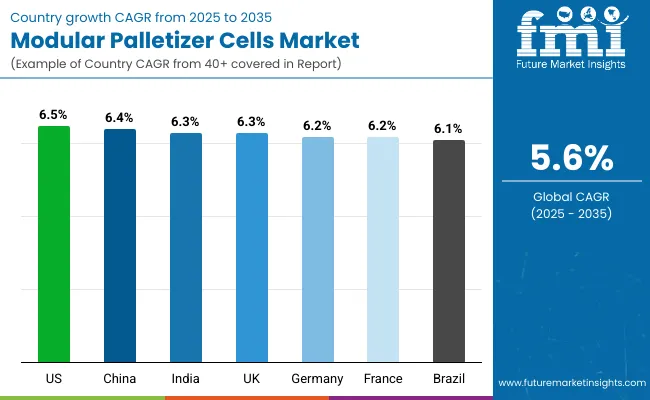

The modular palletizer cells market will expand from USD 2.8 billion in 2025 to USD 4.8 billion by 2035, progressing at a CAGR of 5.6%. Automation and robotics integration across logistics and food industries drive adoption. Robotic palletizer cells dominate due to high-speed stacking and precision.

| Metric | Value |

|---|---|

| Industry Size (2025E) | USD 2.8 billion |

| Industry Value (2035F) | USD 4.8 billion |

| CAGR (2025 to 2035) | 5.6% |

Between 2025 and 2030, market growth of USD 1.1 billion will arise from digital control adoption. Between 2030 and 2035, an additional USD 0.9 billion will be driven by AI-enabled pallet pattern optimization. Asia-Pacific continues as the fastest-growing region.

Between 2020 and 2024, the market advanced through automation in warehousing and manufacturing. Robotics and modular assembly systems improved efficiency and reduced manual handling.

By 2035, global revenues will reach USD 4.8 billion, with manufacturers emphasizing AI-assisted stacking logic and quick configuration changeovers. Asia-Pacific and North America will drive high-throughput demand, while Europe focuses on safety and hybrid cobot systems.

Growth is fueled by rising industrial automation, labor shortages, and the need for flexible, modular automation in packaging and logistics. Compact footprint systems reduce floor space and energy consumption.

Food, pharmaceutical, and e-commerce sectors increasingly deploy palletizer cells for packaging consistency and throughput optimization. Manufacturers prioritize collaborative automation that supports rapid line integration.

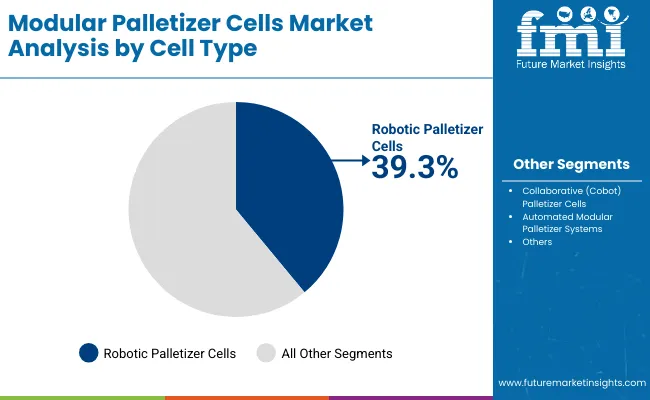

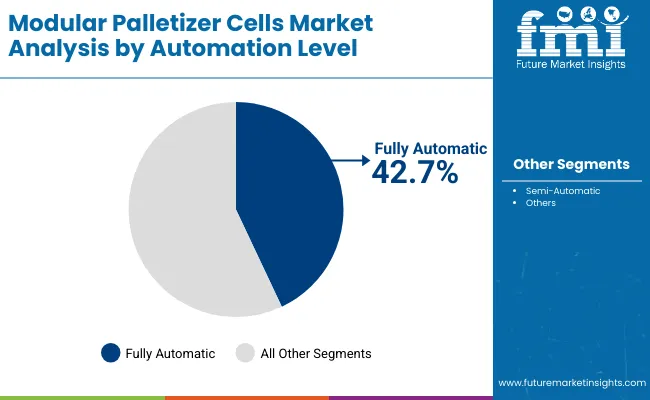

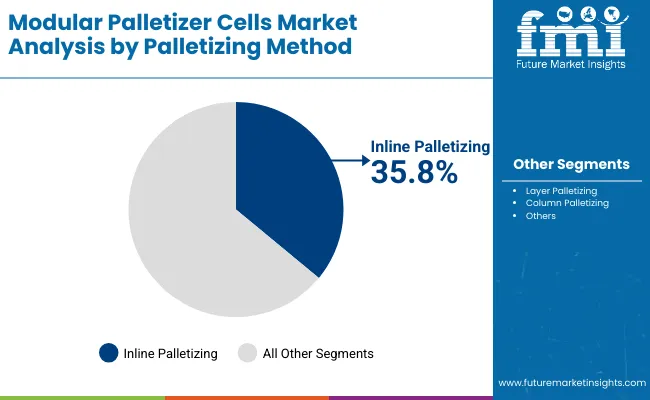

The market is segmented by cell type, automation level, palletizing method, end-use industry, and region. Cell types include robotic, collaborative (cobot), and automated modular systems. Automation levels include fully and semi-automatic models. Palletizing methods include inline, layer, and column systems.

Robotic palletizer cells will account for 39.3% share in 2025 due to their versatility, speed, and reduced downtime. These systems enable multi-line flexibility in manufacturing.

By 2035, innovations in gripper design and visual guidance will enhance operational precision and safety.

Fully automatic systems will hold a 42.7% share in 2025, driven by productivity optimization and reduced operational labor.

Future growth will rely on integrated diagnostics and predictive maintenance using AI algorithms.

Inline palletizing will capture 35.8% share in 2025, ensuring continuous product flow and uniform stacking.

By 2035, integration with vision-assisted quality control will expand adoption across packaging lines.

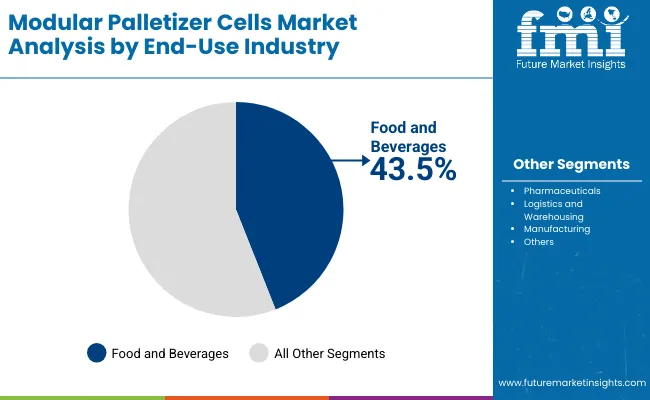

The food and beverage segment will lead with a 43.5% share in 2025, driven by automated packaging for efficiency and hygiene.

Future growth will focus on modular robotics with energy-efficient actuators for faster cycle times.

Rising e-commerce logistics, warehouse modernization, and robotic innovation are major growth drivers.

High system cost and complex integration remain barriers for SMEs.

Cobots and AI-driven modular configurations open opportunities for low-volume, high-variability production.

Hybrid palletizing systems combining AI-based control and real-time monitoring lead ongoing trends.

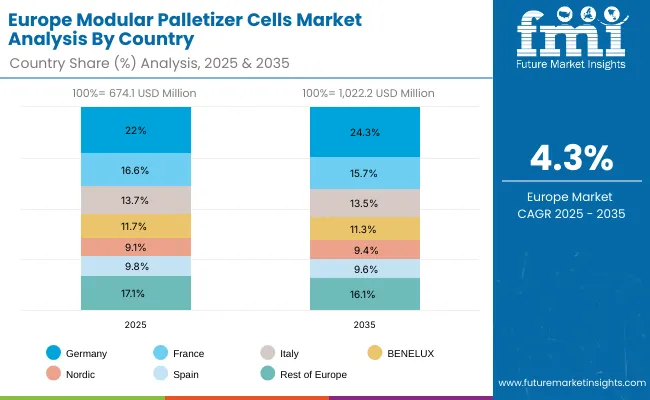

The global modular palletizer cells market is expanding as automation, robotics, and smart manufacturing become central to industrial operations. Asia-Pacific leads adoption, driven by rapid digitalization and large-scale factory automation, while North America prioritizes modular scalability and integrated logistics. Europe continues to invest in precision robotics and energy-efficient designs under Industry 4.0 standards. Modular palletizing systems are increasingly valued for their flexibility, space efficiency, and ability to enhance throughput in packaging, logistics, and warehousing sectors.

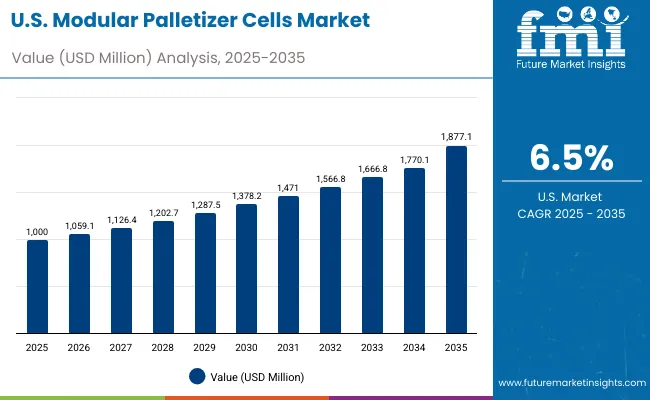

The USA. market will grow at a CAGR of 6.5% from 2025 to 2035, fueled by rapid automation in manufacturing and logistics. AI-assisted robots are optimizing material flow and pallet organization across diverse industries. The transition to high-speed, modular palletizers is improving packaging productivity and minimizing labor dependency. Collaborative robots (cobots) are being deployed to enhance safety, adaptability, and workforce efficiency within modern warehouse and production facilities.

Germany will expand at a CAGR of 6.2%, supported by Industry 4.0 initiatives and the integration of smart robotics. Multi-line palletizing systems are being widely implemented to improve operational flexibility and space utilization. Smart vision-guided robots are enhancing precision and reducing packaging errors. Demand from the food and logistics sectors is accelerating adoption, as German manufacturers prioritize quality, modularity, and compliance with EU automation and sustainability standards.

The UK market will grow at a CAGR of 6.3%, driven by rising warehouse automation and labor optimization. Compact palletizer cells are increasingly replacing manual stacking in logistics and e-commerce operations. Robotics adoption is being accelerated by the country’s growing fulfillment and cold-chain infrastructure. The use of cobots for flexible, multi-shift production is improving efficiency while ensuring safety and ergonomic compliance in fast-paced environments.

China will grow at a CAGR of 6.4%, leading Asia-Pacific in innovation and scale. Robotics manufacturing hubs are expanding under government-led industrial automation programs. Modular palletizer systems are replacing fixed-line setups in food, beverage, and electronics industries. Continuous advancements in AI, motion control, and system connectivity are improving operational margins and establishing China as a global supplier of smart palletizing solutions.

India will grow at a CAGR of 6.3%, supported by packaging modernization and growing FMCG automation. Flexible palletizing systems are being introduced across logistics, food, and beverage industries to meet rising throughput demands. Domestic assembly of palletizer units is increasing with government support for manufacturing. As automation spreads to mid-scale industries, modular palletizing systems are becoming key to productivity and cost-efficiency improvements.

Japan will grow at a CAGR of 6.9%, propelled by advanced robotics innovation and space-efficient industrial systems. Compact modular palletizers are addressing the spatial limitations of Japanese factories and warehouses. Hybrid automation solutions combining AI and precision robotics are enhancing flexibility. Export demand for high-speed cobots and robotic integration technologies continues to strengthen Japan’s presence in global palletizing automation markets.

South Korea will lead with a CAGR of 7.0%, supported by smart robotics and 5G-enabled industrial automation. AI-driven pallet planning systems are improving layout optimization and reducing material handling time. Automation in food and electronics plants is expanding rapidly. The integration of IoT and 5G connectivity enhances real-time monitoring and operational uptime, solidifying South Korea’s leadership in advanced modular palletizing technologies.

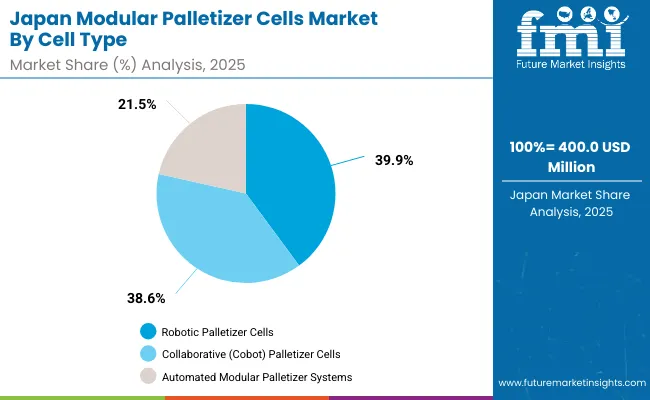

Japan’s modular palletizer cells market, valued at USD 400.0 million in 2025, is led by robotic palletizer cells owing to their precision and compatibility with automated production lines. Collaborative (cobot) palletizer cells follow, gaining traction for their flexible deployment and workforce safety integration. Automated modular palletizer systems are expanding rapidly as smart factories evolve under Industry 4.0 initiatives. Japan’s advanced manufacturing infrastructure continues to drive high adoption of robotic and intelligent palletizing technologies.

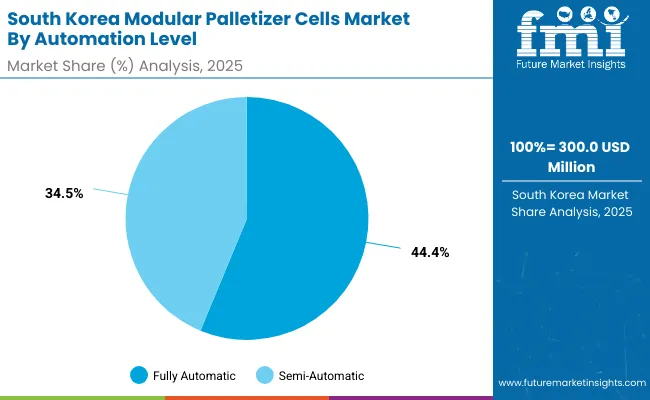

South Korea’s modular palletizer cells market, valued at USD 300.0 million in 2025, is dominated by fully automatic systems due to rising automation in packaging and logistics sectors. Semi-automatic palletizers retain significance across mid-sized industries seeking cost-efficient automation integration. Rapid advancements in robotic vision, end-of-arm tooling, and real-time data monitoring are enhancing precision and reducing downtime. South Korea’s industrial automation policies and digital innovation investments reinforce the growth of efficient palletizing operations.

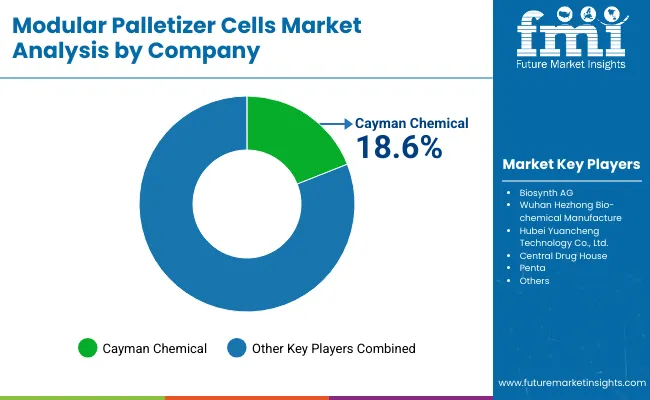

The market is moderately consolidated, led by TopTier (Robopac USA), Brenton (ProMach), Columbia/Okura, Premier Tech, Columbia Machine, ABB Robotics, KUKA Robotics, FANUC, and nVenia (ARPAC/Duravant).

TopTier and Brenton lead in modular design innovation, while ABB and KUKA specialize in intelligent robotics for heavy-duty applications. FANUC’s cobots emphasize real-time adaptability for high-mix production.

Key Developments of Modular Palletizer Cells Market

| Item | Value |

|---|---|

| Quantitative Units | USD 2.8 Billion |

| By Cell Type | Robotic, Collaborative (Cobot), Automated Modular Systems |

| By Automation Level | Fully Automatic, Semi-Automatic |

| By Palletizing Method | Inline, Layer, Column |

| By End-Use Industry | Food & Beverages, Pharma, Logistics, Manufacturing |

| Key Companies Profiled | TopTier (Robopac USA), Brenton (ProMach), Columbia/Okura, Premier Tech, Columbia Machine, ABB Robotics, KUKA Robotics, FANUC, nVenia (ARPAC/ Duravant) |

| Additional Attributes | Growth driven by automation, smart robotics, and modular design flexibility. |

The market will be valued at USD 2.8 billion in 2025.

The market will reach USD 4.8 billion by 2035.

The market will grow at a CAGR of 5.7%.

Robotic palletizer cells will dominate with a 39.3% share in 2025.

Fully automatic systems will lead with a 42.7% share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Modular Rolling Mill Market Size and Share Forecast Outlook 2025 to 2035

Modular Fiber Optical Spectrometers Market Size and Share Forecast Outlook 2025 to 2035

Palletizer Market Size and Share Forecast Outlook 2025 to 2035

Modular Process Skid Packages Market Forecast and Outlook 2025 to 2035

Modular Robotic Market Size and Share Forecast Outlook 2025 to 2035

Modular Trailer Market Forecast and Outlook 2025 to 2035

Modular Substation Market Size and Share Forecast Outlook 2025 to 2035

Modular Rotary Table Market Size and Share Forecast Outlook 2025 to 2035

Modularised Emulsion Plant Market Size and Share Forecast Outlook 2025 to 2035

Modular Self-Contained Aisle and Racking Systems Market Size and Share Forecast Outlook 2025 to 2035

Modular Flooring Market Size and Share Forecast Outlook 2025 to 2035

Modular Furniture Market Size and Share Forecast Outlook 2025 to 2035

Modular Fitness Furniture Market Size and Share Forecast Outlook 2025 to 2035

Modular Chillers Market Size and Share Forecast Outlook 2025 to 2035

Modular & Prefabricated Construction Market Size and Share Forecast Outlook 2025 to 2035

Modular Kitchen Baskets Market Size and Share Forecast Outlook 2025 to 2035

Modular Data Center Market Analysis - Size, Share, and Forecast 2025 to 2035

Modular Instrumentation Platform Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Modular UPS Market Growth - Trends & Forecast 2025 to 2035

Modular Energy Control System Market Growth – Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA