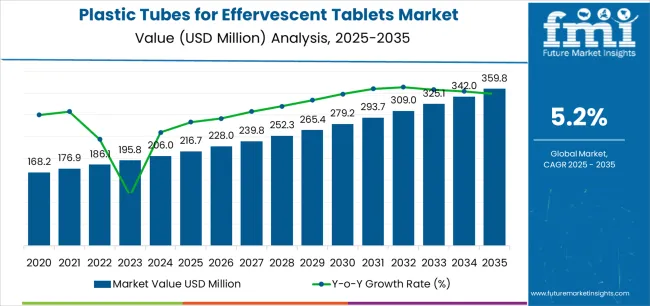

The global plastic tubes for effervescent tablets market, valued at USD 216.7 million in 2025, is projected to reach USD 359.7 million by 2035, expanding at a CAGR of 5.2%, driven by rising demand for moisture-resistant and tamper-proof packaging in pharmaceutical and nutraceutical formulations, increasing consumption of effervescent tablets across healthcare and wellness sectors, and the growing preference for lightweight, recyclable plastic tubes that enhance product shelf life and portability. The plastic tubes for effervescent tablets market enters a sustained growth phase from 2025 to 2035, demonstrating consistent expansion in pharmaceutical packaging technology and dosage form protection solutions. The market trajectory from USD 216.7 million in 2025 to USD 359.7 million by 2035 reflects accelerating adoption of specialized packaging systems, moisture barrier optimization, and child-resistant closure integration across pharmaceutical manufacturers, nutraceutical producers, and contract packaging operations.

The initial five-year period (2025-2030) shows the market advancing from USD 216.7 million to approximately USD 279.2 million, adding USD 62.5 million in value, representing 44% of the total forecast expansion. This phase features rapid adoption of moisture-resistant tube designs, driven by expanding effervescent tablet production volumes and increasing demand for protective packaging solutions that maintain product integrity across diverse storage conditions. Enhanced barrier properties and closure system reliability become standard requirements rather than premium features during this period.

The subsequent five years (2030-2035) witness continued expansion from USD 279.2 million to USD 359.7 million, contributing an additional USD 80.5 million or 56% of the decade's growth. This period is characterized by widespread market penetration of advanced tube designs with integrated desiccant systems, compatibility with automated filling lines, and alignment with pharmaceutical serialization standards. The market evolution indicates fundamental changes in how pharmaceutical facilities approach effervescent tablet protection and distribution, with manufacturers positioned to capitalize on growing demand across multiple tube specifications and application segments.

| Period | Primary Revenue Buckets | Share | Notes |

|---|---|---|---|

| Today | Standard tube sales (various lengths, materials) | 48% | Volume-driven, commodity pricing |

| Closure systems & caps | 22% | Integrated child-resistant, tamper-evident | |

| Desiccant integration & silica gel inserts | 18% | Moisture protection requirements | |

| Custom printing & labeling services | 12% | Brand differentiation, regulatory compliance | |

| Future (3-5 yrs) | Smart packaging tubes | 35-40% | QR codes, temperature indicators, serialization |

| Sustainable material alternatives | 20-25% | Bio-based plastics, recycled content | |

| Integrated moisture control systems | 15-20% | Advanced desiccant technology, molecular sieves | |

| Automation-ready tube designs | 12-15% | High-speed line compatibility, orientation features | |

| Value-added services | 10-12% | Regulatory support, validation documentation | |

| Digital tracking solutions | 5-8% | Supply chain visibility, anti-counterfeiting |

At-a-Glance Metrics

| Metric | Value |

|---|---|

| Market Value (2025) | USD 216.7 million |

| Market Forecast (2035) | USD 359.7 million |

| Growth Rate | 5.2% CAGR |

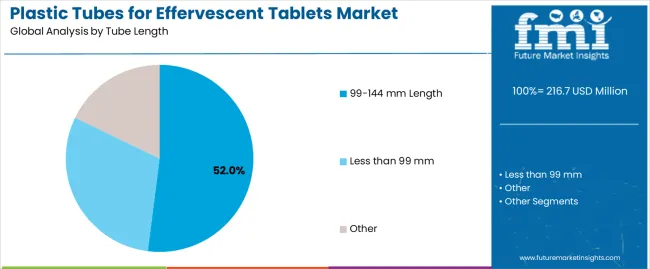

| Leading Tube Length | 99-144 mm Length |

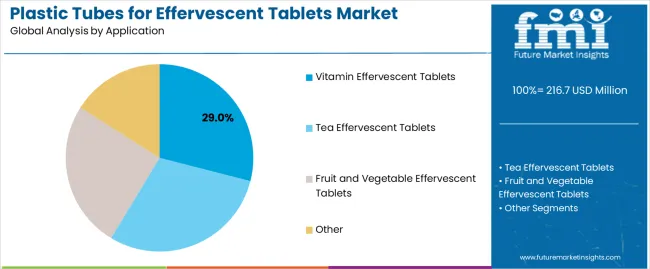

| Primary Application | Vitamin Effervescent Tablets |

The market demonstrates solid fundamentals with 99-144 mm length tubes capturing dominant market position through optimal size compatibility and pharmaceutical packaging efficiency. Vitamin effervescent tablet applications drive primary demand, supported by expanding supplement consumption and health-conscious consumer behavior. Geographic expansion concentrates in Asian markets with growing pharmaceutical manufacturing capabilities, while European regions maintain steady adoption driven by established effervescent tablet production and stringent packaging standards. Tube length optimization and material specification advancements enable manufacturers to meet diverse pharmaceutical packaging requirements while maintaining moisture barrier effectiveness and closure system reliability across varied distribution environments.

Primary Classification: The market segments by tube length into less than 99 mm, 99-144 mm, and other length categories, representing the progression from compact packaging formats to standard pharmaceutical tube specifications for comprehensive effervescent tablet protection and dispensing optimization.

Secondary Classification: Application segmentation divides the market into vitamin effervescent tablets, tea effervescent tablets, fruit and vegetable effervescent tablets, and other specialized formulations, reflecting distinct requirements for moisture protection, product compatibility, and consumer convenience standards.

Regional Classification: Geographic distribution spans East Asia, South Asia Pacific, Western Europe, North America, Latin America, and Middle East & Africa, with Asian markets leading production growth while European regions demonstrate strong consumption patterns driven by established effervescent tablet markets.

The segmentation structure reveals packaging evolution from basic tube containers toward sophisticated protection systems with enhanced moisture barriers and pharmaceutical compliance capabilities, while application diversity extends from vitamin supplements to specialized beverage and nutritional tablet formulations requiring precise packaging specifications.

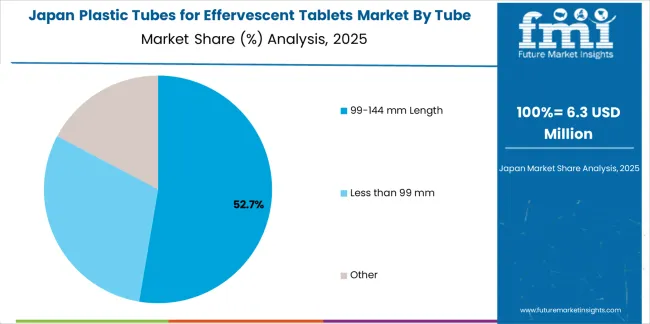

Market Position: The 99-144 mm length tubes command the leading position in the plastic tubes for effervescent tablets market with 52% market share through optimal size balance, superior compatibility with standard effervescent tablet formats, and pharmaceutical packaging efficiency that enables manufacturers to achieve ideal product protection across diverse tablet formulations and consumer applications.

Value Drivers: The segment benefits from pharmaceutical manufacturer preference for standardized tube dimensions that provide consistent packaging performance, efficient filling line integration, and consumer convenience without requiring significant packaging equipment modifications. Standard length features enable automated filling compatibility, adequate tablet capacity, and integration with existing pharmaceutical packaging infrastructure, where dimensional consistency and regulatory compliance represent critical manufacturing requirements.

Competitive Advantages: The 99-144 mm tubes differentiate through proven dimensional reliability, consistent moisture barrier characteristics, and integration with automated pharmaceutical packaging systems that enhance production efficiency while maintaining optimal product protection suitable for diverse vitamin and supplement applications.

Key market characteristics:

Less than 99 mm length tubes maintain a 28% market position in the plastic tubes for effervescent tablets market through compact packaging advantages and portability benefits. These tubes appeal to manufacturers requiring travel-size formats with competitive pricing for on-the-go supplement applications. Market growth is driven by single-serve tablet demand, emphasizing convenient packaging solutions and consumer portability through optimized compact designs.

Other length tubes capture 20% market share through specialized packaging requirements for large-format tablets, multi-tablet packaging, and custom pharmaceutical applications. These formats demand flexible tube dimensions capable of accommodating diverse tablet sizes while providing effective moisture protection and operational versatility.

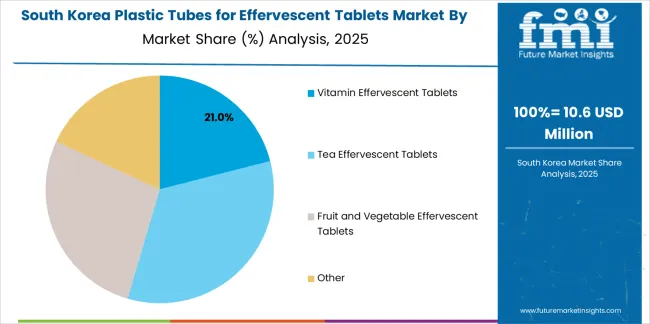

Market Context: Vitamin effervescent tablets demonstrate the highest growth rate in the plastic tubes for effervescent tablets market with 40% share, through widespread consumer adoption of supplement formats and increasing focus on convenient vitamin delivery systems, nutritional fortification, and health maintenance applications that maximize bioavailability while maintaining product stability.

Appeal Factors: Vitamin tablet manufacturers prioritize packaging reliability, moisture barrier effectiveness, and integration with existing pharmaceutical distribution infrastructure that enables product integrity across multiple storage environments. The segment benefits from substantial consumer health investment and supplement consumption growth that emphasizes acquisition of protective tube packaging for vitamin preservation and dispensing convenience applications.

Growth Drivers: Health supplement expansion programs incorporate tube packaging as standard protection for effervescent vitamin products, while pharmaceutical channel growth increases demand for packaging capabilities that comply with pharmaceutical standards and minimize product degradation during storage and distribution.

Market Challenges: Varying tablet formulations and moisture sensitivity levels may limit packaging standardization across different vitamin products or manufacturing scenarios.

Application dynamics include:

Tea effervescent tablet applications capture 25% share through specialized packaging requirements for beverage tablet formats, flavor preservation needs, and consumer convenience applications. These products demand protective tube systems capable of maintaining aroma integrity while providing effective dispensing access and moisture resistance capabilities.

Fruit and vegetable effervescent tablet applications account for 20% share, including nutritional supplement innovations, flavor variety expansion, and functional beverage tablet formulations requiring specialized packaging for optimal freshness and product appeal.

| Category | Factor | Impact | Why It Matters |

|---|---|---|---|

| Driver | Effervescent tablet consumption growth (vitamins, supplements, hydration products) | ★★★★★ | Expanding effervescent format adoption requires specialized moisture-resistant packaging with consistent barrier performance and consumer convenience features. |

| Driver | Pharmaceutical packaging requirements (moisture protection, child-resistant closures) | ★★★★★ | Regulatory standards transform advanced tube designs from optional to mandatory; manufacturers providing compliant packaging solutions gain competitive advantage. |

| Driver | E-commerce expansion & direct-to-consumer distribution | ★★★★☆ | Online pharmaceutical sales need robust packaging with tamper-evidence and moisture protection; demand for reliable tube packaging expanding addressable market. |

| Restraint | Raw material price volatility (polypropylene, polyethylene costs) | ★★★★☆ | Plastic resin price fluctuations impact tube manufacturing costs; increases price sensitivity and affects profit margins in commodity segments. |

| Restraint | Sustainability concerns & single-use plastic regulations | ★★★☆☆ | Environmental regulations and consumer preferences push for alternative materials; traditional plastic tube manufacturers face adaptation challenges and compliance costs. |

| Trend | Sustainable packaging materials & circular economy initiatives | ★★★★★ | Recycled content integration, bio-based alternatives, and closed-loop systems transform packaging specifications; environmental compatibility becomes core value proposition. |

| Trend | Smart packaging integration & serialization requirements | ★★★★☆ | Track-and-trace capabilities, QR codes, and temperature indicators enhance product security; digital integration and anti-counterfeiting features drive competitive differentiation. |

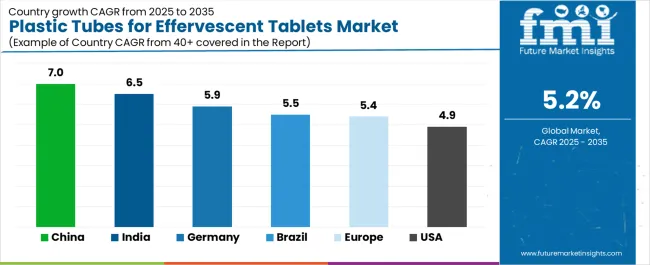

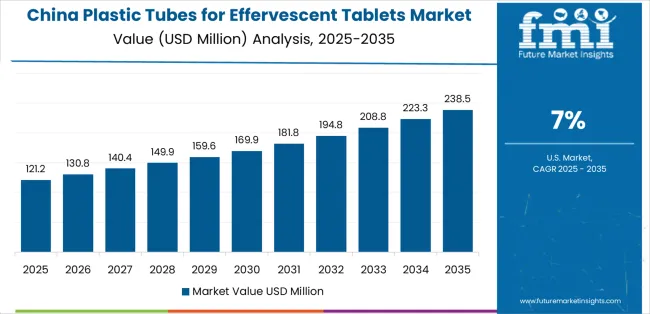

The plastic tubes for effervescent tablets market demonstrates varied regional dynamics with Growth Leaders including China (7.0% growth rate) and India (6.5% growth rate) driving expansion through pharmaceutical manufacturing growth and supplement consumption increases. Steady Performers encompass Germany (5.9% growth rate), United States (4.9% growth rate), and developed regions, benefiting from established effervescent tablet markets and pharmaceutical packaging standards. Emerging Markets feature Brazil (5.5% growth rate) and developing regions, where supplement adoption and pharmaceutical packaging modernization support consistent growth patterns.

Regional synthesis reveals East Asian markets leading expansion through pharmaceutical production growth and supplement consumption increases, while European countries maintain steady development supported by established effervescent tablet markets and stringent packaging standards. South Asian markets show accelerating growth driven by rising health awareness and supplement market development.

| Region/Country | 2025-2035 Growth | How to win | What to watch out |

|---|---|---|---|

| China | 7.0% | Lead with high-volume production capacity | Raw material sourcing; quality consistency |

| India | 6.5% | Focus on cost-effective solutions | Infrastructure gaps; distribution challenges |

| Germany | 5.9% | Offer premium sustainable options | Over-specification; regulatory complexity |

| United States | 4.9% | Provide compliance documentation | Material certification costs; testing requirements |

| Brazil | 5.5% | Value-oriented pricing models | Import dependencies; currency variations |

| Europe | 5.4% | Push sustainable materials | Recycling infrastructure; regional variations |

China establishes fastest market growth through aggressive pharmaceutical packaging expansion programs and comprehensive supplement manufacturing development, integrating plastic tubes for effervescent tablets as standard components in vitamin production and pharmaceutical packaging installations. The country's 7.0% growth rate reflects government initiatives promoting pharmaceutical manufacturing self-sufficiency and domestic packaging capabilities that mandate use of protective tube systems in pharmaceutical and nutraceutical facilities. Growth concentrates in major manufacturing hubs, including Guangdong, Zhejiang, and Jiangsu provinces, where pharmaceutical packaging technology development showcases integrated tube production that appeals to manufacturers seeking cost-effective packaging solutions and high-volume production capabilities.

Chinese manufacturers develop efficient tube production systems combining domestic material sourcing advantages with advanced manufacturing features, including automated production lines and quality control integration. Distribution channels through pharmaceutical packaging suppliers and contract manufacturing service providers expand market access, while government support for pharmaceutical packaging development supports adoption across diverse supplement and pharmaceutical segments.

Strategic Market Indicators:

In Mumbai, Bangalore, and Hyderabad, pharmaceutical facilities and supplement manufacturing plants implement plastic tube packaging as standard protection for effervescent vitamin products and nutritional tablet applications, driven by increasing consumer health awareness and pharmaceutical manufacturing capacity expansion programs that emphasize product protection importance. The market holds a 6.5% growth rate, supported by growing middle-class supplement consumption and pharmaceutical manufacturing development programs that promote protective packaging systems for vitamin and nutritional tablet facilities. Indian manufacturers adopt tube packaging providing reliable moisture protection and pharmaceutical compliance features, particularly appealing in urban regions where product quality and consumer safety represent critical market requirements.

Market expansion benefits from growing pharmaceutical packaging capabilities and technology adoption from international suppliers that enable domestic production of quality tube systems for pharmaceutical and supplement applications. Packaging adoption follows patterns established in pharmaceutical packaging sectors, where cost-effectiveness and moisture barrier performance drive procurement decisions and operational deployment.

Market Intelligence Brief:

Germany establishes technology leadership through comprehensive pharmaceutical packaging standards and advanced material development programs, integrating plastic tubes for effervescent tablets across pharmaceutical and supplement applications. The country's 5.9% growth rate reflects established pharmaceutical industry relationships and mature packaging technology adoption that supports widespread use of high-quality tube systems in pharmaceutical and contract manufacturing facilities. Growth concentrates in major pharmaceutical centers, including Bavaria, Baden-Württemberg, and North Rhine-Westphalia, where pharmaceutical packaging technology showcases advanced tube designs that appeal to manufacturers seeking proven moisture protection capabilities and regulatory compliance applications.

German packaging manufacturers leverage engineering expertise and comprehensive quality management systems, including material certification programs and sustainability initiatives that create customer confidence and operational advantages. The market benefits from stringent regulatory standards and pharmaceutical requirements that mandate protective packaging use while supporting material innovation and sustainability advancement.

Market Intelligence Brief:

United States demonstrates mature market characteristics through established pharmaceutical packaging infrastructure and comprehensive supplement distribution networks, integrating plastic tubes for effervescent tablets across vitamin and pharmaceutical applications. The country's 4.9% growth rate reflects stable pharmaceutical industry demand and mature packaging adoption that supports consistent use of tube systems in pharmaceutical and online distribution channels. Growth concentrates in major pharmaceutical regions, including New Jersey, California, and Pennsylvania, where pharmaceutical packaging solutions showcase established tube deployment that appeals to manufacturers seeking regulatory compliance and consumer convenience applications.

American packaging suppliers maintain strong relationships with pharmaceutical companies and supplement brands, providing material certification documentation and compliance support that create operational reliability. The market benefits from established FDA regulations and pharmaceutical standards that ensure packaging quality while supporting innovation in sustainable materials and smart packaging features.

Market Intelligence Brief:

Brazil's market expansion benefits from diverse supplement demand, including pharmaceutical manufacturing growth in São Paulo and Minas Gerais, vitamin supplement consumption increases, and pharmaceutical packaging modernization programs that increasingly incorporate tube solutions for product protection applications. The country maintains a 5.5% growth rate, driven by rising health awareness and increasing recognition of protective packaging benefits, including moisture control and product integrity maintenance.

Market dynamics focus on cost-effective tube solutions balancing adequate moisture protection with affordability considerations important to Brazilian pharmaceutical manufacturers and supplement brands. Growing pharmaceutical industrialization creates continued demand for modern tube packaging in new production facilities and manufacturing modernization projects.

Strategic Market Considerations:

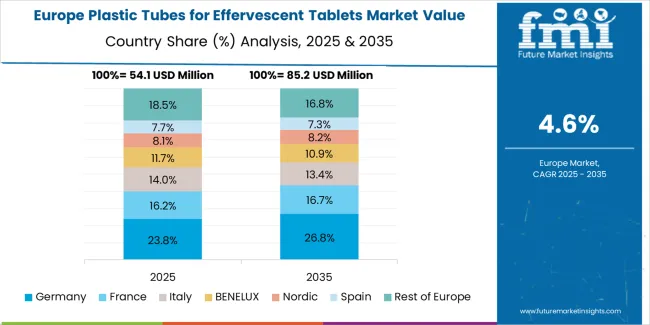

The plastic tubes for effervescent tablets market in Europe is projected to grow from USD 68.2 million in 2025 to USD 115.9 million by 2035, registering a CAGR of 5.4% over the forecast period. Germany is expected to maintain its leadership position with a 32.4% market share in 2025, supported by its advanced pharmaceutical packaging infrastructure and major supplement manufacturing centers.

United Kingdom follows with a 19.8% share in 2025, driven by comprehensive pharmaceutical packaging standards and supplement market development initiatives. France holds a 17.6% share through established effervescent tablet production and pharmaceutical packaging requirements. Italy commands a 14.2% share, while Spain accounts for 10.3% in 2025. The rest of Europe region is anticipated to gain momentum, expanding its collective share from 5.7% to 6.4% by 2035, attributed to increasing tube packaging adoption in Nordic countries and emerging Central European pharmaceutical facilities implementing packaging modernization programs.

Japan shows stable market development with 3.9% growth rate, supported by established pharmaceutical packaging standards and mature supplement consumption patterns. The market benefits from stringent quality requirements and consumer preference for premium packaging solutions, with manufacturers in Tokyo, Osaka, and Nagoya regions leading adoption of advanced moisture barrier tube systems. Japanese pharmaceutical facilities prioritize packaging reliability and material quality, creating demand for certified tube products that meet pharmaceutical manufacturing standards and consumer safety expectations.

South Korea demonstrates accelerating market expansion driven by pharmaceutical manufacturing development and supplement consumption growth in Seoul, Busan, and Incheon industrial regions. The market reflects increasing adoption of automated tube packaging systems and integration with high-speed pharmaceutical production lines. Korean manufacturers emphasize packaging innovation and material quality, supporting demand for advanced tube designs with enhanced moisture protection and pharmaceutical compliance features that align with export-oriented pharmaceutical production strategies.

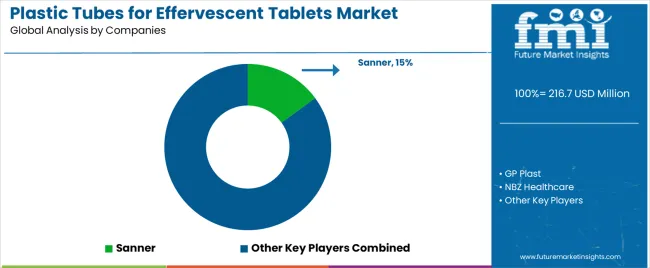

The plastic tubes for effervescent tablets market features a moderately consolidated competitive structure with approximately 12-18 established players serving pharmaceutical and supplement manufacturers globally. The top 4-6 manufacturers hold approximately 55-60% market share by revenue, with competition based on production capacity, material quality, closure system integration, and pharmaceutical compliance support. Market leadership is maintained through manufacturing scale, technical expertise in moisture barrier technology, global distribution networks, and ability to provide customized tube solutions meeting diverse pharmaceutical specifications.

Margin differentiation opportunities exist in sustainable material development, smart packaging integration, and value-added services including regulatory documentation support and validation assistance. Basic tube manufacturing and standard dimensions are becoming increasingly commoditized, with price competition intensifying in high-volume segments. Premium segments focused on sustainable alternatives, integrated desiccant systems, and pharmaceutical-grade materials maintain higher margins through technical differentiation and compliance certification requirements.

Strategic positioning varies across manufacturer categories, with global packaging companies leveraging broad product portfolios and established pharmaceutical relationships, specialized tube manufacturers focusing on technical innovation and customization capabilities, regional producers competing on cost efficiency and local market proximity, and material suppliers expanding into finished tube production to capture downstream value. Pharmaceutical compliance requirements and material certification standards create barriers to entry while supporting premium pricing for certified manufacturers.

Technology innovation focuses on sustainable material alternatives including recycled content integration and bio-based polymers, smart packaging features with serialization and track-and-trace capabilities, advanced moisture barrier systems with integrated desiccants, automation-compatible designs for high-speed production lines, and child-resistant closure integration meeting pharmaceutical safety standards. Manufacturers investing in sustainability credentials and digital packaging capabilities position for long-term growth as pharmaceutical customers prioritize environmental responsibility and supply chain transparency alongside traditional performance requirements.

| Stakeholder | What they actually control | Typical strengths | Typical blind spots |

|---|---|---|---|

| Global packaging platforms | Production scale, material sourcing, multi-region distribution | Broad pharmaceutical relationships, certified quality systems | Customization flexibility; regional responsiveness |

| Technical specialists | Material innovation, barrier technology, closure systems | Advanced moisture protection, pharmaceutical compliance | Production capacity; price competitiveness |

| Regional manufacturers | Local supply chains, rapid delivery, market proximity | Cost efficiency, flexible customization, regional compliance | Material innovation; global expansion capability |

| Sustainable innovators | Bio-based materials, recycled content, circular systems | Environmental credentials, future-ready solutions | Production scale; cost parity challenges |

| Contract packagers | Integrated filling services, turnkey solutions, logistics | Complete packaging solutions, pharmaceutical relationships | Material procurement; technology development |

| Item | Value |

|---|---|

| Quantitative Units | USD 216.7 million |

| Tube Length | Less than 99 mm, 99-144 mm, Other |

| Application | Vitamin Effervescent Tablets, Tea Effervescent Tablets, Fruit and Vegetable Effervescent Tablets, Other |

| Regions Covered | East Asia, South Asia Pacific, Western Europe, North America, Latin America, Eastern Europe, Middle East & Africa |

| Countries Covered | China, India, Germany, United States, Brazil, United Kingdom, Japan, South Korea, France, Italy, and 20+ additional countries |

| Key Companies Profiled | Sanner, GP Plast, NBZ Healthcare, Suzhou Super Packaging, Shijiazhuang Xinfuda, Yantai Cmcpack, Hoffmann Neopac, Lameplast, CCL Industries, Romaco Group |

| Additional Attributes | Dollar sales by tube length and application categories, regional production trends across East Asia, South Asia Pacific, and Western Europe, competitive landscape with pharmaceutical packaging manufacturers and material suppliers, pharmaceutical customer preferences for moisture barrier effectiveness and closure system reliability, integration with pharmaceutical production lines and quality management systems, innovations in sustainable materials and smart packaging technology, and development of automation-compatible tube designs with enhanced performance and pharmaceutical compliance capabilities. |

The global plastic tubes for effervescent tablets market is estimated to be valued at USD 216.7 million in 2025.

The market size for the plastic tubes for effervescent tablets market is projected to reach USD 359.8 million by 2035.

The plastic tubes for effervescent tablets market is expected to grow at a 5.2% CAGR between 2025 and 2035.

The key product types in plastic tubes for effervescent tablets market are 99-144 mm length, less than 99 mm and other.

In terms of application, vitamin effervescent tablets segment to command 0.0% share in the plastic tubes for effervescent tablets market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Plastic Banding Market Size and Share Forecast Outlook 2025 to 2035

Plastic Tube Market Size and Share Forecast Outlook 2025 to 2035

Plastic Jar Packaging Market Forecast and Outlook 2025 to 2035

Plastic Cases Market Size and Share Forecast Outlook 2025 to 2035

Plastic Jar Industry Analysis in the United States Size and Share Forecast Outlook 2025 to 2035

Plastic Cutlery Market Forecast and Outlook 2025 to 2035

Plastic Vial Market Forecast and Outlook 2025 to 2035

Plastic Hot and Cold Pipe Market Forecast and Outlook 2025 to 2035

Plastic Retort Can Market Size and Share Forecast Outlook 2025 to 2035

Plastic Gears Market Size and Share Forecast Outlook 2025 to 2035

Plastic Additive Market Size and Share Forecast Outlook 2025 to 2035

Plastic Market Size and Share Forecast Outlook 2025 to 2035

Plastic Vials and Ampoules Market Size and Share Forecast Outlook 2025 to 2035

Plastic Healthcare Packaging Market Size and Share Forecast Outlook 2025 to 2035

Plastic Bottle Industry Analysis in Malaysia Size and Share Forecast Outlook 2025 to 2035

Plastic Drum Industry Analysis in Malaysia Size and Share Forecast Outlook 2025 to 2035

Plastic Healthcare Packaging Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Plastic Healthcare Packaging Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Plastic Healthcare Packaging Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Plastic Bottles Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA