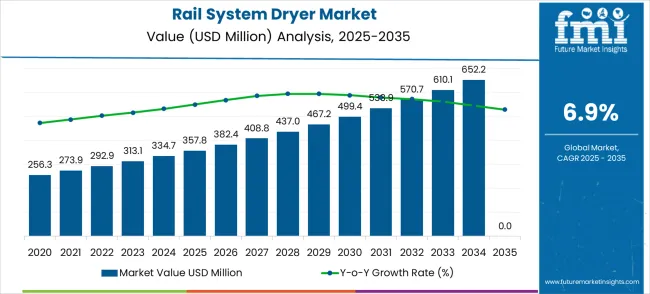

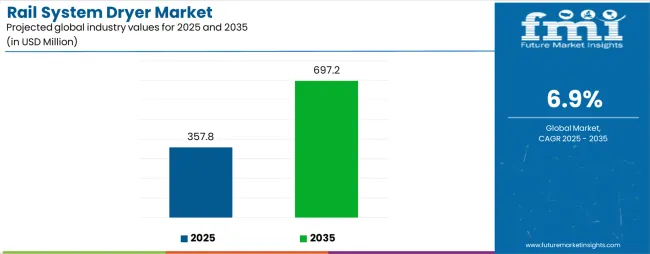

The rail system dryer market is poised for steady growth over the next decade, with an estimated CAGR of 6.9% from 2025 to 2035. The market is projected to grow from USD 357.8 million in 2025 to USD 697.2 million by 2035. This upward trend can be attributed to the increasing need for efficient and reliable drying systems in the railway sector. With rail systems being central to transportation in many regions, maintaining operational efficiency and minimizing downtime are critical concerns. Rail system dryers play a crucial role in preventing moisture damage and ensuring smooth operations, thus driving demand for these systems across various markets.

The growing investment in rail infrastructure, particularly in developing regions, is expected to further accelerate the market growth. As global economies place more emphasis on improving transportation networks and reducing delays caused by moisture-related issues, the adoption of advanced rail system dryers is expected to rise. Furthermore, these systems' ability to enhance the durability and performance of trains and their components under various environmental conditions strengthens their position in the market. As transportation continues to evolve, the rail system dryer market will likely experience sustained demand driven by these practical considerations.

The rail system dryer market accounts for approximately 4% of the overall rail transportation market, driven by the need for effective maintenance systems that ensure optimal train performance in diverse weather conditions. In the industrial drying equipment market, it holds around 5%, reflecting the growing adoption of drying technologies tailored for specialized sectors like rail transportation. Within the transportation maintenance equipment market, the market share is about 6%, with rail system dryers becoming essential in maintaining the efficiency and safety of train operations.

The train components market sees approximately 3% share, as dryers are integrated into the overall train maintenance systems. Lastly, in the infrastructure maintenance market, it holds about 4%, driven by the need for effective systems to maintain transportation infrastructure. These percentages underscore the rail system dryer’s pivotal role in supporting the efficiency and longevity of rail systems, facilitating smoother operations.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 357.8 million |

| Market Forecast Value (2035) | USD 697.2 million |

| Forecast CAGR (2025-2035) | 6.9% |

Market expansion is being supported by comprehensive railway infrastructure modernization programs and increasing emphasis on operational safety through advanced moisture control systems in critical rail applications. Modern railway operators increasingly demand reliable compressed air drying solutions that ensure consistent brake performance, prevent system corrosion, and minimize maintenance downtime through superior moisture removal capabilities. The integration of advanced drying technologies with sophisticated monitoring systems enables unprecedented levels of system reliability and operational efficiency.

The growing focus on preventive maintenance and asset optimization is driving substantial demand for rail system dryers from established railway equipment manufacturers with proven track records of reliability and technical excellence. Railway operators are investing significantly in advanced air treatment technologies that offer superior moisture control while providing enhanced system longevity and reduced operational costs. Railway safety standards are establishing performance benchmarks that favor integrated drying systems with advanced monitoring capabilities and superior reliability characteristics.

The railway industry's transformation toward digitalization and predictive maintenance is creating substantial demand for intelligent drying systems capable of delivering real-time performance monitoring and automated maintenance scheduling through advanced sensor technologies. The transportation sector continues to drive innovation in compressed air applications while maintaining safety and environmental standards, leading to development of breakthrough rail system dryers with enhanced efficiency and comprehensive performance monitoring capabilities.

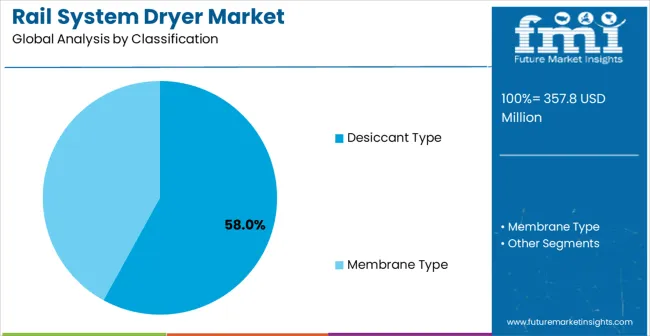

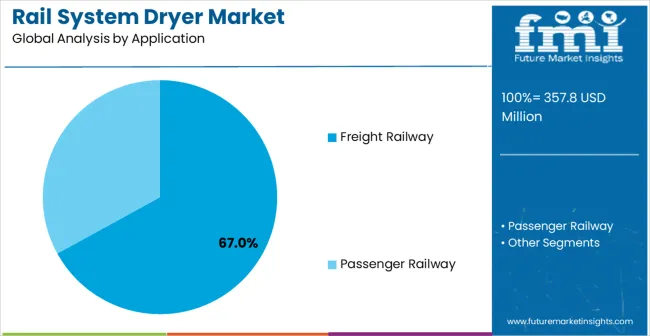

The market is segmented by product type, application, and region. By product type, the market is divided into desiccant type, membrane type, and other configurations. Based on application, the market is categorized into freight railway and passenger railway applications. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

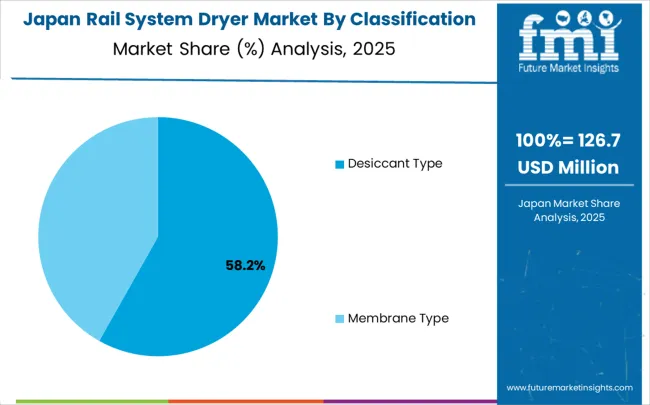

Desiccant type configurations are projected to account for 58% of the rail system dryer market in 2025. This leading share is supported by superior moisture removal efficiency and proven reliability in demanding railway applications requiring consistent compressed air quality. Desiccant-based systems provide exceptional drying performance and operational flexibility, making them the preferred choice for railway operators seeking comprehensive moisture control and long-term system reliability. The segment benefits from advanced desiccant materials, regenerative drying cycles, and automated control systems that have created entirely new levels of operational efficiency in railway air treatment applications.

Modern desiccant rail system dryers incorporate sophisticated regeneration control and advanced monitoring systems that enable optimal drying performance, predictive maintenance alerts, and energy-efficient operation while ensuring consistent air quality and extended system lifespan. These innovations have transformed railway maintenance practices while providing exceptional moisture removal for brake systems, door operations, and other pneumatic applications through continuous air quality optimization and intelligent system management. The freight railway market particularly drives demand for desiccant solutions, as these applications require robust moisture control and reliable performance to ensure safe and efficient cargo transportation operations.

Additionally, the passenger railway and urban transit sectors increasingly adopt advanced desiccant technologies to optimize system reliability and support critical safety systems through precise moisture control and comprehensive air quality management. The growing emphasis on operational excellence creates opportunities for specialized desiccant dryers designed for high-frequency service and comprehensive railway system integration.

Freight railway applications are expected to represent 67% of rail system dryer demand in 2025. This dominant share reflects the extensive freight rail network infrastructure and critical importance of reliable compressed air systems for heavy-duty cargo transportation operations. Freight railway applications require robust drying solutions that ensure consistent brake performance, prevent system corrosion, and minimize maintenance downtime across extended operational cycles. The segment benefits from increasing freight transportation demand and growing investment in rail infrastructure modernization projects.

The global freight transportation expansion drives significant demand for rail system dryers that provide exceptional reliability and performance optimization for heavy-duty railway operations requiring consistent compressed air quality and system durability. These applications require drying systems with superior capacity and robust construction to ensure reliable performance across diverse weather conditions and intensive operational schedules. The segment benefits from growing intermodal transportation adoption and increasing emphasis on rail freight efficiency and operational cost optimization.

Industrial transportation and logistics sectors contribute substantially to market growth as freight operators implement advanced air treatment systems in locomotive fleets and comprehensive railway infrastructure modernization projects. The growing adoption of automated freight systems creates opportunities for specialized rail system dryers designed for unmanned operations and integrated system monitoring. Additionally, the trend toward sustainable transportation drives demand for energy-efficient drying systems that enable comprehensive freight railway optimization through integrated pneumatic system management and environmental compliance.

The rail system dryer market is advancing steadily due to comprehensive railway infrastructure investments and growing emphasis on operational safety through advanced moisture control technologies across all railway segments. However, the market faces challenges including high initial investment costs, need for specialized technical expertise, and varying regulatory requirements across different railway applications. Railway safety standards and environmental regulations continue to influence product development and market adoption patterns.

The revolutionary advances in sensor technology, IoT connectivity, and predictive analytics are enabling unprecedented system monitoring capabilities while maintaining operational efficiency and cost-effectiveness standards. Advanced monitoring architectures and railway-specific diagnostic systems provide superior performance optimization and predictive maintenance capabilities, enabling proactive system management and comprehensive operational excellence. These technologies are particularly valuable for critical railway applications that require sophisticated monitoring, accurate performance prediction, and actionable maintenance recommendations.

Modern rail system dryer manufacturers are implementing breakthrough energy optimization and comprehensive sustainability initiatives that enable reduced power consumption while supporting environmental compliance and operational cost optimization requirements. Advanced system architectures enable optimized energy usage, reduced environmental impact, and enhanced operational efficiency while ensuring superior drying performance and regulatory compliance verification.

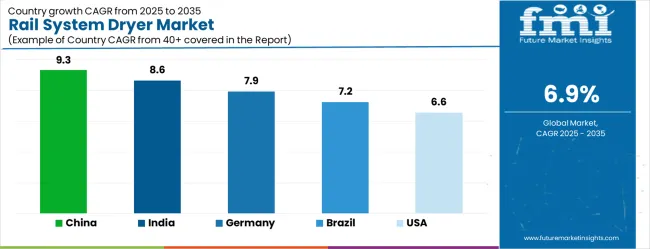

| Country | CAGR (2025-2035) |

|---|---|

| China | 9.3% |

| India | 8.6% |

| Germany | 7.9% |

| Brazil | 7.2% |

| United States | 6.6% |

| United Kingdom | 5.9% |

| Japan | 5.2% |

The rail system dryer market is experiencing robust growth, with China leading at an impressive 9.3% CAGR through 2035, driven by massive railway infrastructure expansion and rapidly growing freight transportation network development. India follows at 8.6%, supported by extensive railway modernization projects and increasing emphasis on operational efficiency. Germany records strong growth at 7.9%, emphasizing technological innovation excellence and advanced railway system integration. Brazil grows substantially at 7.2%, benefiting from expanding railway infrastructure and freight transportation development. The United States shows solid growth at 6.6%, focusing on railway modernization and freight system optimization. The United Kingdom maintains steady expansion at 5.9%, supported by infrastructure investment programs. Japan demonstrates consistent growth at 5.2%, emphasizing precision engineering and advanced railway technology integration.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

The rail system dryer market in China is projected to exhibit the highest growth rate with a CAGR of 9.3% through 2035, driven by the country's position as a global railway infrastructure leader and massive domestic investment in high-speed rail and freight transportation networks. The extensive railway development programs and unprecedented investment in transportation infrastructure are creating extraordinary opportunities for advanced rail system dryer adoption. Major railway operators are implementing world-leading compressed air technologies to serve both the enormous domestic transportation market and international railway development projects while establishing leadership in railway system efficiency.

Railway infrastructure revolution and transportation network expansion are supporting explosive adoption of advanced rail system dryer technologies across freight and passenger railway operations, driving demand for sophisticated moisture control capabilities and comprehensive system integration solutions. Global railway leadership and transportation infrastructure scale are creating unprecedented opportunities for Chinese railway technology companies in worldwide transportation markets requiring advanced drying functionality and competitive cost structures.

The rail system dryer market in India is expanding at a CAGR of 8.6%, supported by the country's extensive railway network modernization and rapidly accelerating infrastructure development across passenger and freight transportation segments. The enormous railway system scale and increasing emphasis on operational efficiency are driving extraordinary rail system dryer demand potential. Railway operators are leveraging India's vast transportation network while implementing advanced moisture control solutions to capture emerging opportunities in railway safety and operational excellence.

Railway modernization acceleration and infrastructure development expansion are creating unprecedented opportunities for rail system dryer integration across diverse railway categories requiring cost-effective solutions and localized technical support capabilities. Domestic railway technology development and international collaboration programs are driving investments in compressed air technologies throughout major railway corridors and freight transportation networks.

The rail system dryer market in Germany is projected to grow at a CAGR of 7.9%, supported by the country's leadership in railway technology innovation and advanced transportation system development across high-speed rail, freight transportation, and urban transit sectors. German railway technology companies are implementing sophisticated rail system dryer development that meets stringent safety standards and environmental requirements while delivering superior performance and operational reliability. The market is characterized by focus on technological innovation, advanced system integration, and compliance with comprehensive railway safety and environmental regulations.

Railway innovation investments are prioritizing advanced compressed air technologies that demonstrate superior reliability characteristics and environmental compliance while meeting German transportation quality and safety standards for railway applications. Innovation programs and railway technology development initiatives are driving adoption of precision-engineered drying systems that support optimal railway performance and enhanced transportation system integration.

The rail system dryer market in Brazil is growing at a CAGR of 7.2%, driven by expanding transportation infrastructure development and increasing railway investment across freight transportation and urban transit market segments. The growing emphasis on efficient transportation systems and increasing railway network expansion are creating substantial opportunities for rail system dryer market development. Railway operators are adapting advanced drying technologies to support growing freight transportation demand and infrastructure modernization while maintaining cost accessibility and local market relevance.

Transportation infrastructure development and railway network expansion are facilitating adoption of reliable rail system dryer solutions capable of meeting diverse railway requirements and operational patterns across traditional and emerging transportation segments. Regional railway technology capability development and transportation infrastructure expansion are creating demand for localized drying systems that meet railway operator preferences and infrastructure accessibility requirements.

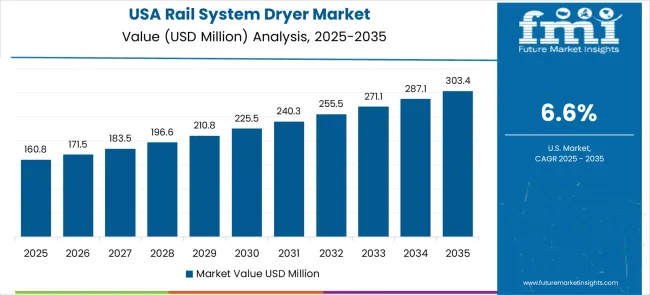

The rail system dryer market in the United States is expanding at a CAGR of 6.6%, driven by the country's focus on railway infrastructure modernization and freight transportation system optimization across Class I railroads and regional transportation networks. The sophisticated railway technology ecosystem and operator investment in advanced rail system technologies create substantial demand for high-performance compressed air solutions. The market benefits from freight transportation growth and premium railway technology segments across logistics, manufacturing, and energy transportation applications.

Railway modernization programs and freight system optimization initiatives are driving adoption of advanced rail system dryers that offer superior reliability and operational efficiency for demanding freight transportation applications. Infrastructure investment programs and railway technology advancement initiatives are supporting demand for sophisticated drying systems that meet premium railway performance requirements and operational excellence standards.

The rail system dryer market in the United Kingdom is projected to grow at a CAGR of 5.9%, supported by ongoing railway technology advancement and increasing investment in transportation system optimization across passenger rail and freight transportation applications. Railway technology companies are investing in advanced rail system dryer development that provides superior functionality while meeting safety requirements and environmental compliance for railway applications. The market is characterized by focus on system integration, operational efficiency, and advanced technology implementation across diverse railway segments.

Railway technology advancement and system integration programs are supporting adoption of advanced rail system dryers that meet contemporary safety and performance standards for railway applications. Infrastructure enhancement initiatives and railway technology excellence programs are creating demand for sophisticated drying systems that provide superior railway performance and operational compliance verification.

The rail system dryer market in Japan is expanding at a CAGR of 5.2%, driven by the country's emphasis on railway technology excellence and precision engineering across high-speed rail, urban transit, and freight transportation sectors. Japanese railway technology companies are developing sophisticated compressed air applications that incorporate precision engineering and operational optimization principles. The market benefits from focus on technological precision, system reliability, and continuous innovation in railway technology development and transportation system integration.

Railway technology excellence programs and precision engineering initiatives are driving advancement of premium rail system dryers that demonstrate superior technology characteristics and operational reliability. Transportation technology excellence programs and railway advancement initiatives are supporting adoption of precision-engineered drying solutions that optimize railway performance and ensure consistent operation in demanding transportation applications and system integration scenarios.

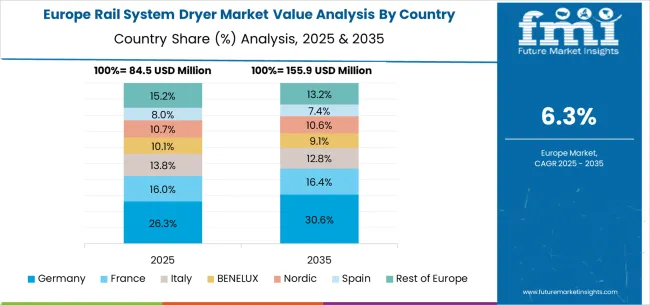

The rail system dryer market in Europe is projected to grow from USD 89.5 million in 2025 to USD 153.4 million by 2035, registering a CAGR of 5.6% over the forecast period. Germany is expected to maintain its leadership with a 35.2% share in 2025, supported by its advanced railway technology industry and transportation system excellence. The United Kingdom follows with 22.8% market share, driven by railway infrastructure investment and transportation technology development. France holds 18.9% of the European market, benefiting from high-speed rail expansion and transportation system advancement. Italy and Spain collectively represent 15.4% of regional demand, with growing focus on railway modernization and transportation infrastructure development. The Rest of Europe region accounts for 7.7% of the market, supported by railway technology development in Eastern European countries and Nordic transportation innovation.

The rail system dryer market is defined by intense competition among established railway equipment manufacturers, specialized compressed air companies, and innovative technology providers. Companies are investing substantially in research and development, advanced product design, reliability validation, and railway system integration to deliver superior, dependable, and cost-effective rail system dryer solutions. Strategic partnerships, technological advancement, and rapid market expansion are central to achieving market leadership and railway operator adoption.

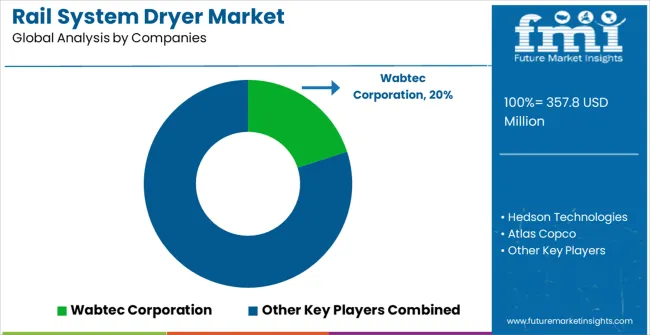

Wabtec Corporation, operating globally, offers comprehensive rail system dryer solutions with focus on operational reliability, safety compliance, and seamless railway system integration across locomotive applications, freight systems, and passenger rail networks. Hedson Technologies, specialized provider, delivers advanced compressed air treatment systems with emphasis on energy efficiency, predictive maintenance, and intelligent system monitoring capabilities. Atlas Copco provides innovative industrial air treatment solutions with focus on railway applications and global technical support. Norgren (IMI Precision Engineering) offers precision pneumatic systems with advanced control and monitoring features for critical railway applications.

AVENTICS (Emerson) provides comprehensive pneumatic solutions with emphasis on railway safety and operational excellence applications. Tsunami delivers specialized rail system dryers with focus on harsh environment performance and extended operational reliability. Trident Pneumatics Pvt. Ltd. offers cost-effective solutions with emphasis on emerging market accessibility and local technical support.

Eldridge USA, Meier Prozesstechnik, SolvAir, and Graham-White offer specialized railway equipment expertise, innovative product development, and technical advancement across compressed air systems and railway technology networks.

The rail system dryer market underpins railway safety advancement, transportation efficiency optimization, infrastructure modernization, and sustainable transportation evolution. With accelerating railway technology adoption, infrastructure investment expansion, and safety regulation requirements, the sector faces pressure to balance innovation velocity, operational cost optimization, and regulatory compliance verification. Coordinated contributions from governments, industry bodies, OEMs/technology integrators, suppliers, and investors will accelerate the transition toward efficient, reliable, and universally accessible rail system dryer ecosystems.

| Item | Value |

|---|---|

| Quantitative Units | USD 357.8 million |

| Type | Desiccant Type, Membrane Type, Others |

| Application | Freight Railway, Passenger Railway |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Germany, India, China, United Kingdom, Japan, Brazil, and other 40+ countries |

| Key Companies Profiled | Wabtec Corporation, Hedson Technologies, Atlas Copco, Norgren (IMI Precision Engineering), AVENTICS (Emerson), Tsunami, Trident Pneumatics Pvt. Ltd., Eldridge USA, Meier Prozesstechnik, SolvAir, Graham-White |

The global smart welding monitoring solution market is estimated to be valued at USD 1,239.7 million in 2025.

The market size for the smart welding monitoring solution market is projected to reach USD 2,283.8 million by 2035.

The smart welding monitoring solution market is expected to grow at a 6.3% CAGR between 2025 and 2035.

The key product types in smart welding monitoring solution market are real-time monitoring systems, iot-integrated platforms, welding management software and others.

In terms of application, automotive segment to command 42.0% share in the smart welding monitoring solution market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Railway Communication Equipment Market Size and Share Forecast Outlook 2025 to 2035

Railway Rolling Stock Market Forecast and Outlook 2025 to 2035

Rail Transit Vehicle Glass Market Size and Share Forecast Outlook 2025 to 2035

Railway CNC Wheel Lathe Market Size and Share Forecast Outlook 2025 to 2035

Railway Flatcar Market Size and Share Forecast Outlook 2025 to 2035

Rail Freight Market Size and Share Forecast Outlook 2025 to 2035

Railroad Market Size and Share Forecast Outlook 2025 to 2035

Rail Gearbox Market Size and Share Forecast Outlook 2025 to 2035

Railway Roof Switches Market Size and Share Forecast Outlook 2025 to 2035

Rail Tank Cars Market Size and Share Forecast Outlook 2025 to 2035

Railway Window Market Size and Share Forecast Outlook 2025 to 2035

Railway Maintenance Machinery Market Size and Share Forecast Outlook 2025 to 2035

Rail Freight Digital Transformation Market Size and Share Forecast Outlook 2025 to 2035

Rail Logistics Market Size and Share Forecast Outlook 2025 to 2035

Railway Control Stands Market Size and Share Forecast Outlook 2025 to 2035

Railway Horn Market Size and Share Forecast Outlook 2025 to 2035

Railway Axlebox Housing Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Railway After-Cooler Market - Growth & Demand 2025 to 2035

Rail Brace Market Analysis - Size, Share & Forecast 2025 to 2035

Railway Fishplate Market Growth – Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA