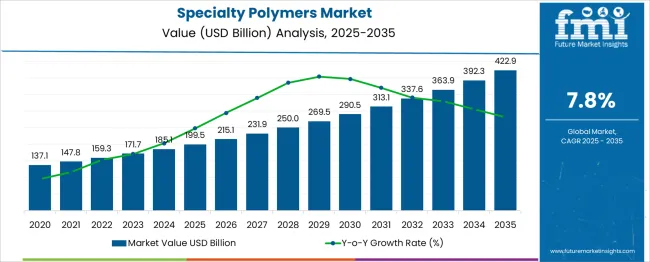

The global specialty polymers market is projected to grow from USD 199.5 billion in 2025 to approximately USD 422.9 billion by 2035, recording an absolute increase of USD 223.3 billion over the forecast period. This translates into a total growth of 111.9%, with the market forecast to expand at a compound annual growth rate (CAGR) of 7.8% between 2025 and 2035. The overall market size is expected to grow by nearly 2.12X during the same period, supported by increasing demand from automotive and aerospace industries, rising adoption of lightweight materials, and growing focus on eco-friendly and high-performance polymer solutions.

Between 2025 and 2030, the specialty polymers market is projected to expand from USD 199.5 billion to USD 290.4 billion, resulting in a value increase of USD 90.9 billion, which represents 40.7% of the total forecast growth for the decade. This phase of growth will be shaped by rising demand for high-performance materials in automotive lightweighting, increasing adoption of advanced polymers in medical devices, and growing penetration of specialty polymers in electronics and semiconductor applications. Chemical manufacturers are expanding their specialty polymer portfolios to address the growing demand for engineered solutions across diverse industrial applications.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 199.5 billion |

| Forecast Value in (2035F) | USD 422.9 billion |

| Forecast CAGR (2025 to 2035) | 7.8% |

From 2030 to 2035, the market is forecast to grow from USD 290.4 billion to USD 422.9 billion, adding another USD 132.3 billion, which constitutes 59.3% of the overall ten-year expansion. This period is expected to be characterized by expansion of eco-friendly polymer technologies, integration of smart materials with IoT capabilities, and development of next-generation bio-based specialty polymers. The growing adoption of circular economy principles and regulatory focus on environment friendly will drive demand for recyclable and biodegradable specialty polymer solutions with enhanced performance characteristics.

Between 2020 and 2025, the specialty polymers market experienced steady expansion, driven by increasing demand for lightweight materials in transportation, growing adoption of high-performance polymers in medical applications, and rising focus on energy-efficient solutions. The market developed as industries recognized the need for advanced materials that could deliver superior performance while meeting stringent regulatory requirements. Technological advancements in polymer chemistry and processing techniques began focusing on the importance of specialty polymers in enabling next-generation product innovations.

Market expansion is being supported by the increasing demand for high-performance materials that can withstand extreme conditions and deliver superior functionality compared to conventional polymers. Modern industries are increasingly focused on lightweight, durable, and chemically resistant materials that can enhance product performance while reducing overall system weight and energy consumption. Specialty polymers' proven efficacy in applications ranging from aerospace components to medical implants makes them preferred materials in premium industrial formulations.

The growing focuses on eco-friendly and environmental responsibility is driving demand for specialty polymers derived from renewable sources and designed for recyclability. Industrial preference for multifunctional materials that combine mechanical strength, chemical resistance, and processing efficiency is creating opportunities for innovative polymer formulations. The rising influence of Industry 4.0 and smart manufacturing trends is also contributing to increased adoption of specialty polymers across different sectors and applications.

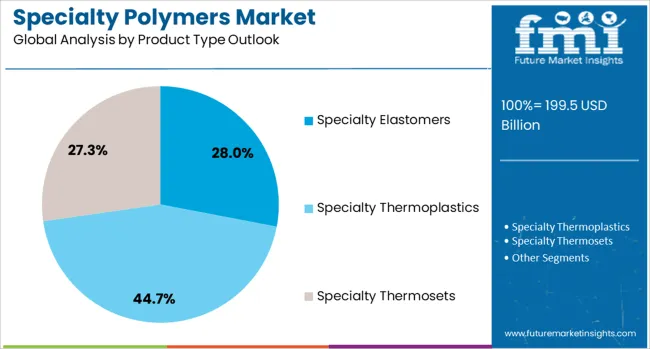

The market is segmented by source, form, product type, end use, and region. By source, the market is divided into synthetic, natural, and semisynthetic polymers. Based on form, the market is categorized into solid and liquid formulations. In terms of product type, the market is segmented into specialty elastomers (including fluoroelastomers, fluorosilicone rubber, liquid silicone rubber, natural rubber, and others), specialty thermoplastics (including polyolefins, polyimides, vinylic polymers, polyphenyles, and others), specialty thermosets (including epoxy, polyester, vinyl ester, polyimides, and others), biodegradable polymers, liquid crystal polymers, and others. By end use, the market is classified into transport, building & construction, medical & healthcare, textile, food & beverage, electrical & electronics, cosmetics & personal care, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

The transport end use segment is projected to account for 27% of the specialty polymers market in 2025, reaffirming its position as the category's largest application sector. The automotive, aerospace, and marine industries increasingly rely on specialty polymers to achieve weight reduction goals while maintaining structural integrity and performance standards. Advanced polymer materials directly address industry needs for fuel efficiency, emissions reduction, and enhanced durability in demanding operational environments.

This segment forms the foundation of market growth, as it represents the most significant and rapidly expanding application area for high-performance polymers. Engineering validation and regulatory approvals continue to strengthen confidence in specialty polymer solutions for critical transport applications. With stricter fuel efficiency standards and growing focuses on electric vehicle development, transport applications align with both performance enhancement and eco-friendly objectives across global automotive and aerospace markets.

Specialty thermoplastics are projected to represent 44.7% of specialty polymers demand in 2025, underscoring their role as the leading product category for applications requiring strength, lightweight performance, and design versatility. Industries gravitate toward specialty thermoplastics for their excellent mechanical properties, processability, and resistance to heat, chemicals, and wear. Positioned as high-value engineering materials, specialty thermoplastics offer both structural benefits, such as load-bearing capacity and dimensional stability, and functional benefits, including transparency, flame retardancy, and recyclability.

The segment is supported by the rising adoption of high-performance plastics in automotive, aerospace, electronics, and medical industries, where thermoplastics enable lightweighting and precision component fabrication. Manufacturers are increasingly leveraging advanced compounding techniques, fiber reinforcements, and functional additives to enhance performance characteristics, opening up premium market opportunities. As industries accelerate the shift toward sustainability, electrification, and miniaturization, specialty thermoplastic-based solutions will continue to dominate demand, reinforcing their leadership position within the specialty polymers market.

The synthetic source segment is forecasted to contribute 59.4% of the specialty polymers market in 2025, reflecting the superior control over material properties and consistency that synthetic polymers provide. Industries are increasingly attentive to performance predictability, preferring synthetic specialty polymers that offer precise molecular architecture and tailored functionality for specific applications. This aligns with advanced manufacturing requirements, which focuses on reproducibility, quality control, and optimized processing characteristics.

Synthetic polymers provide enhanced design flexibility, allowing manufacturers to engineer materials with specific combinations of mechanical, thermal, and chemical properties. The segment also benefits from continuous innovation in polymerization technologies and catalyst systems that enable the development of next-generation materials with unprecedented performance capabilities. With heightened performance requirements and demanding application conditions, synthetic specialty polymers serve as critical enablers of technological advancement, making them a fundamental driver of market growth and industrial innovation.

The market is advancing rapidly due to increasing demand for high-performance materials and growing adoption of lightweight solutions across industries. The market faces challenges including raw material price volatility, complex processing requirements, and competition from alternative advanced materials. Innovation in eco-friendly polymer technologies and advanced manufacturing processes continue to influence product development and market expansion patterns.

The growing adoption of circular economy principles is enabling manufacturers to develop specialty polymers from renewable feedstocks and design materials for end-of-life recyclability. Eco-friendly polymer technologies offer environmental benefits, regulatory compliance, and brand positioning advantages that influence purchasing decisions. Research and development investments in bio-based chemistry and polymer recycling technologies are driving innovation in eco-friendly specialty polymer solutions, particularly among industries with stringent environmental commitments.

Modern specialty polymer manufacturers are incorporating smart material technologies such as shape-memory properties, self-healing capabilities, and responsive behavior to environmental stimuli. These technologies improve material functionality while enabling new application possibilities and providing enhanced user experience. Advanced formulation techniques also enable combination products that deliver multiple performance benefits through single material solutions, reducing system complexity and improving overall efficiency.

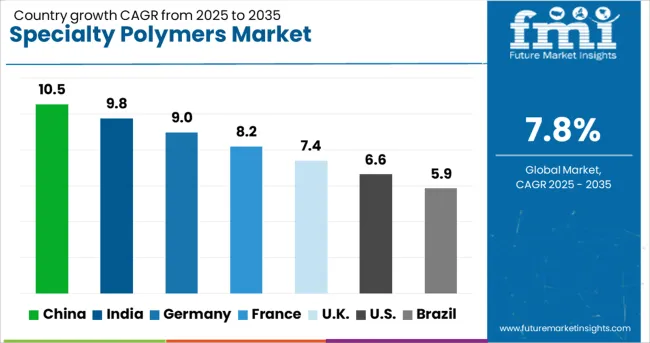

| Country | CAGR (2025-2035) |

|---|---|

| China | 10.5% |

| India | 9.8% |

| Germany | 9.0% |

| France | 8.2% |

| UK | 7.4% |

| USA | 6.6% |

| Brazil | 5.9% |

The specialty polymers market is experiencing robust growth globally, with China leading at a 10.5% CAGR through 2035, driven by massive industrial expansion, government support for advanced materials development, and growing demand from automotive and electronics sectors. India follows closely at 9.8%, supported by rapid infrastructure development, expanding manufacturing base, and increasing adoption of high-performance materials. Germany shows steady growth at 9.0%, focusing on precision engineering applications and automotive innovations. France records 8.2% growth, focusing on aerospace and specialty chemical applications. The United Kingdom shows 7.4% growth, prioritizing advanced materials for energy and medical applications. The report covers an in-depth analysis of 40+ countries; six top-performing countries are highlighted below.

Revenue from specialty polymers in China is projected to exhibit exceptional growth with a CAGR of 10.5% through 2035, driven by massive industrial expansion, government initiatives supporting advanced materials development, and increasing demand from automotive, electronics, and infrastructure sectors. The country's Belt and Road Initiative and focus on high-tech manufacturing are creating significant opportunities for specialty polymer applications across diverse industrial segments.

Revenue from specialty polymers in India is expanding at a CAGR of 9.8%, supported by rapid industrialization, infrastructure development, and increasing adoption of advanced materials across manufacturing sectors. The country's Make in India initiative and growing automotive industry are driving demand for high-performance polymer solutions. International specialty polymer manufacturers are establishing production facilities to serve the expanding Indian market.

Demand for specialty polymers in Germany is projected to grow at a CAGR of 9.0%, supported by the country's leadership in automotive engineering, chemical industry expertise, and advanced manufacturing technologies. German manufacturers prioritize precision, quality, and innovation, positioning specialty polymers as essential materials for high-performance industrial applications. The market is characterized by strong demand for engineered solutions that meet stringent technical specifications.

Revenue from specialty polymers in France is projected to grow at a CAGR of 8.2% through 2035, driven by the country's strength in aerospace, energy, and specialty chemicals industries. French manufacturers focuses on high-performance applications, and innovation. The market benefits from strong research and development capabilities and established partnerships between industry and academic institutions.

Revenue from specialty polymers in the UK is projected to grow at a CAGR of 7.4% through 2035, supported by focus on high-value manufacturing, energy sector innovations, and medical technology development. British industries value performance and regulatory compliance, positioning specialty polymers as critical materials for advanced applications.

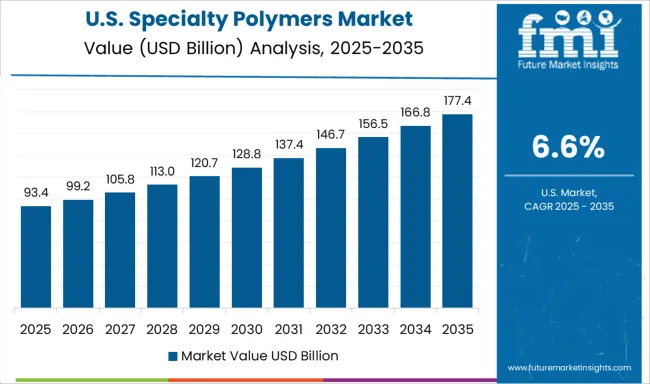

Revenue from specialty polymers in the United States is projected to grow at a CAGR of 6.6% through 2035, supported by the country's leadership in aerospace, medical devices, electronics, and advanced manufacturing technologies. American companies prioritize innovation, performance, and regulatory compliance, making specialty polymers essential materials for critical applications across multiple high-tech industries.

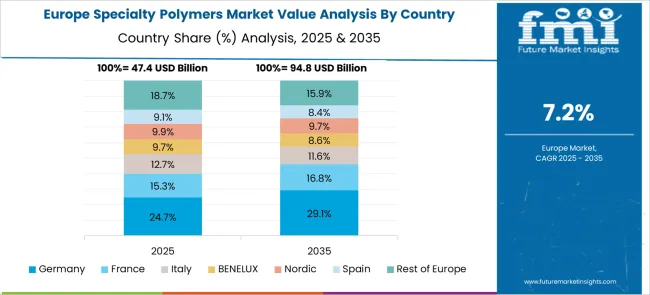

The European specialty polymers market demonstrates sophisticated development across major economies with Germany leading through precision engineering excellence and advanced chemical manufacturing capabilities, supported by companies like BASF SE and Covestro AG pioneering comprehensive polymer solutions focusing on automotive, aerospace, and industrial applications while focusing on eco-friendly and circular economy principles.

The UK shows strength in high-performance materials and regulatory compliance, with companies specializing in advanced polymer technologies meeting strict environmental standards and providing consistent quality outcomes. France contributes through companies like Arkema delivering integrated specialty polymer solutions for aerospace applications. Italy and Spain demonstrate growth in specialized polymer formulations for construction and industrial applications across diverse manufacturing sectors.

The Japanese specialty polymers market demonstrates steady growth driven by precision manufacturing focus, advanced automation technologies, and consumer preference for high-quality polymer systems ensuring superior product consistency and safety compliance throughout manufacturing operations. Companies like Toray Industries, Mitsubishi Chemical Group, and international suppliers establish presence through cutting-edge polymer technologies aligning with Japan's sophisticated manufacturing industry and stringent quality standards while incorporating IoT integration and smart manufacturing capabilities.

The market focuses on automated control systems, mechanical processing excellence, and thermal processing innovations reflecting Japanese manufacturing precision and attention to detail. Growing investment in Industry 4.0 technologies supports intelligent processing systems with real-time monitoring, predictive analytics, and optimized equipment performance for enhanced operational efficiency.

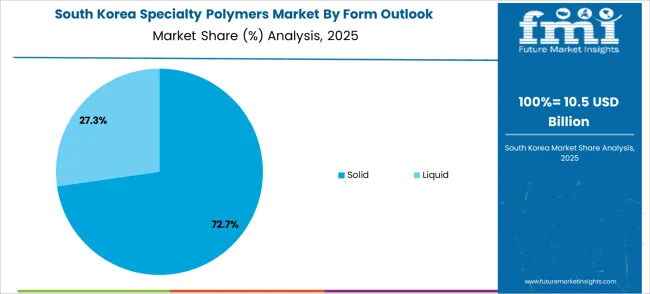

The South Korean specialty polymers market shows emerging growth potential driven by expanding manufacturing industry, increasing adoption of automation technologies, and growing demand for high-performance materials requiring efficient and advanced polymer solutions. The market benefits from South Korea's technological advancement capabilities and increasing focus on manufacturing competitiveness driving investment in modern specialty polymers meeting international quality standards and regulatory requirements.

Korean manufacturers increasingly adopt automatic operation modes, mechanical processing equipment, and integrated polymer systems improving production efficiency and product consistency while ensuring safety compliance. Growing influence of Korean industrial products in global markets supports demand for sophisticated specialty polymers ensuring quality assurance while maintaining cost-effectiveness and operational reliability across manufacturing applications.

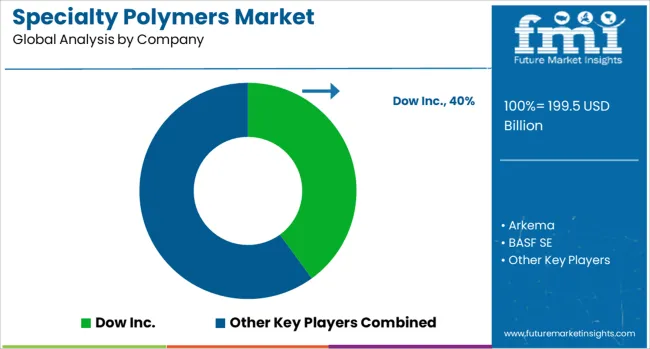

The specialty polymers market is characterized by competition among established chemical companies, specialty materials manufacturers, and innovative technology developers. Companies are investing in advanced polymer chemistry, eco-friendly production processes, application development, and strategic partnerships to deliver high-performance, reliable, and cost-effective specialty polymer solutions. Technology innovation, market diversification, and customer collaboration are central to strengthening product portfolios and competitive positioning.

Dow Inc., USA-based, leads the market with significant global presence, offering comprehensive specialty polymer portfolios with focus on performance materials and eco-friendly solutions. Arkema, France, provides specialized high-performance polymers with focuses on advanced applications and technical expertise. BASF SE, Germany, delivers extensive specialty polymer ranges with focus on automotive, construction, and industrial applications. Evonik Industries AG, Germany, focuses on specialty chemical solutions and custom polymer development.

Covestro AG, Germany, focuses on high-performance polymers for automotive, electronics, and construction applications. Solvay SA, Belgium, provides advanced specialty polymers with focuses on aerospace, automotive, and energy applications. DuPont de Nemours Inc., USA, offers innovation-driven polymer solutions with focus on safety and performance. SABIC, Saudi Arabia, delivers comprehensive polymer portfolios across multiple industrial segments. Celanese Corporation and Eastman Chemical Company provide specialized solutions with focus on engineering applications and customer collaboration.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 199.5 billion |

| Source | Synthetic, Natural, Semisynthetic |

| Form | Solid, Liquid |

| Product Type | Specialty Elastomers (Fluoroelastomers, Fluorosilicone Rubber, Liquid Silicone Rubber, Natural Rubber, Others), Specialty Thermoplastics (Polyolefins, Polyimides, Vinylic Polymer, Polyphenyles, Others), Specialty Thermosets (Epoxy, Polyester, Vinyl Ester, Polyimides, Others), Biodegradable Polymers, Liquid Crystal Polymers, Others |

| End Use | Transport, Building & Construction, Medical & Healthcare, Textile, Food & Beverage, Electrical & Electronics, Cosmetics & Personal Care, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Dow Inc., Arkema, BASF SE, Evonik Industries AG, Covestro AG, Solvay SA, DuPont de Nemours Inc., SABIC, Celanese Corporation, Eastman Chemical Company, Mitsubishi Chemical Group Corporation, Toray Industries Inc., Kuraray Co. Ltd., LG Chem, and Wacker Chemie AG |

| Additional Attributes | Market analysis by polymer chemistry and molecular weight, regional demand trends, competitive landscape, customer preferences for synthetic versus bio-based sources, integration with eco-friendly and circular economy initiatives, innovations in polymer processing, advanced applications development, and strategic partnerships across industrial value chains |

The global specialty polymers market is estimated to be valued at USD 199.5 billion in 2025.

The market size for the specialty polymers market is projected to reach USD 422.9 billion by 2035.

The specialty polymers market is expected to grow at a 7.8% CAGR between 2025 and 2035.

The key product types in specialty polymers market are synthetic, natural and semisynthetic.

In terms of form outlook, solid segment to command 76.1% share in the specialty polymers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Specialty Film Market Size and Share Forecast Outlook 2025 to 2035

Specialty Silica Market Size and Share Forecast Outlook 2025 to 2035

Specialty Food Ingredients Market Size and Share Forecast Outlook 2025 to 2035

Specialty Commercial Deep Fryers Market Size and Share Forecast Outlook 2025 to 2035

Specialty Tapes Market Size and Share Forecast Outlook 2025 to 2035

Specialty Fertilizers Market Size and Share Forecast Outlook 2025 to 2035

Specialty Coatings Market Size and Share Forecast Outlook 2025 to 2035

Specialty Transformer Market Size and Share Forecast Outlook 2025 to 2035

Specialty Chemicals Market Size and Share Forecast Outlook 2025 to 2035

Specialty Nitriles Market Size and Share Forecast Outlook 2025 to 2035

Specialty Fuel Additives Market Size and Share Forecast Outlook 2025 to 2035

Specialty Cultures Market Analysis - Size, Share and Forecast Outlook 2025 to 2035

Specialty Shortenings Market Size and Share Forecast Outlook 2025 to 2035

Specialty Labels Packaging Market Size and Share Forecast Outlook 2025 to 2035

Specialty Commercial Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Specialty Carbon Black Market Size and Share Forecast Outlook 2025 to 2035

Specialty Lighting Market Size and Share Forecast Outlook 2025 to 2035

Specialty Amino Acids Market Size and Share Forecast Outlook 2025 to 2035

Specialty Pulp & Paper Chemicals Market Size, Share & Forecast 2025 to 2035

Specialty Yeast Market Analysis - Size, Growth, and Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA