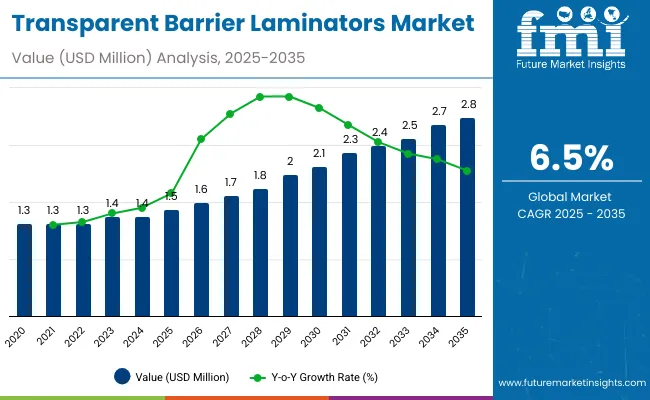

The transparent barrier laminators market will expand from USD 1.5 billion in 2025 to USD 2.9 billion by 2035, growing at a CAGR of 6.5%. Market expansion is driven by increasing use of PET and EVOH-coated films in flexible food packaging. Solventless lamination remains preferred for energy efficiency and low emissions.

| Metric | Value |

|---|---|

| Industry Size (2025E) | USD 1.5 billion |

| Industry Value (2035F) | USD 2.9 billion |

| CAGR (2025 to 2035) | 6.5% |

Between 2025 and 2030, the market will gain USD 0.6 billion due to rising packaging automation. From 2030 to 2035, improved substrate compatibility and bio-based lamination materials will add another USD 0.8 billion. Asia-Pacific will maintain its leadership with advanced converting infrastructure.

From 2020 to 2024, the market was shaped by sustainability mandates and shifts toward solventless systems. Transparent laminates gained adoption across pharmaceutical, food, and electronic packaging sectors for their moisture and oxygen resistance.

By 2035, global revenue will reach USD 2.9 billion, led by demand for recyclable, high-clarity laminates. Technological upgrades in lamination speed, coating uniformity, and digital quality control will drive cost competitiveness and environmental compliance.

The growing preference for flexible packaging with high transparency and protective properties is fueling market expansion. Solventless laminators enable reduced carbon footprint and improved operational safety.

Increasing applications in barrier films for pharmaceuticals and electronics further strengthen demand, while packaging manufacturers prioritize low-waste and energy-efficient conversion systems.

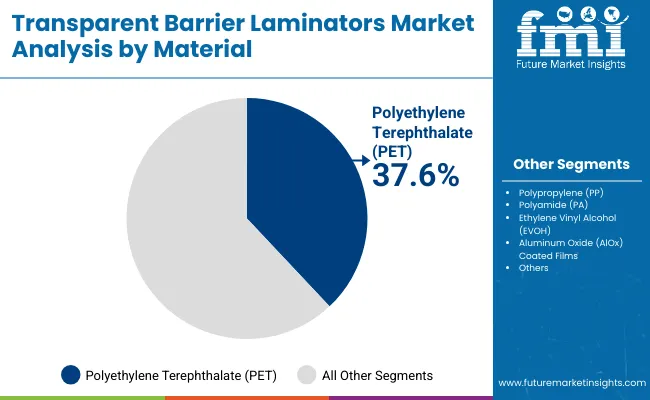

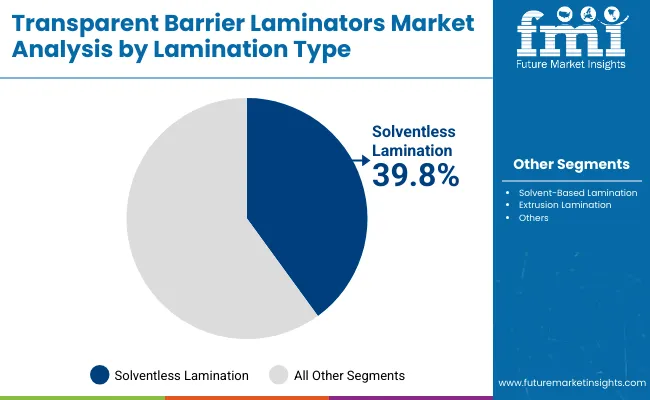

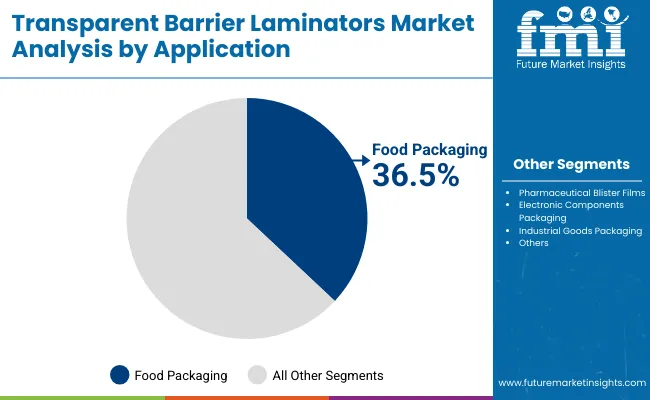

The market is segmented by material, lamination type, application, and region. Materials include PET, PP, PA, EVOH-coated, and AIOx-coated films. Lamination types comprise solventless, solvent-based, and extrusion processes. Applications include food packaging, blister films, electronics packaging, and industrial goods packaging.

PET will account for 37.6% share in 2025, supported by strong tensile properties and clarity. These films enhance printability and barrier performance in flexible packaging.

By 2035, improved recyclability and high-barrier coating integration will consolidate PET’s dominance in food and pharma packaging.

Solventless lamination will hold a 39.8% share in 2025, favored for faster curing, reduced emissions, and cost savings.

Future adoption will accelerate through bio-solvent adhesives and digital monitoring for coating precision.

Food packaging will capture 36.5% share in 2025 as transparent laminates preserve product freshness and branding visibility.

By 2035, demand will rise for recyclable laminates supporting sustainable labeling and extended shelf-life packaging.

Rising demand for high-clarity barrier films and recyclable packaging solutions fuels market growth. Solventless systems cut costs and enhance sustainability.

Initial investment in lamination technology and solvent recovery systems limits adoption among small converters.

The rise of bio-based adhesive formulations and recyclable PET laminates presents significant opportunities.

Trends include multi-layer coating integration, digital lamination control, and hybrid automation across film converting lines.

The global transparent barrier laminators market is growing rapidly as automation, sustainability, and food safety standards reshape packaging operations. Asia-Pacific leads adoption, driven by flexible packaging expansion and large-scale manufacturing investments, while Europe continues to lead regulatory innovation in low-emission laminates. North America emphasizes automation, recyclable materials, and high-barrier performance for food and medical packaging. Worldwide, the market’s evolution is defined by eco-certification, hybrid lamination systems, and precision-driven film technologies.

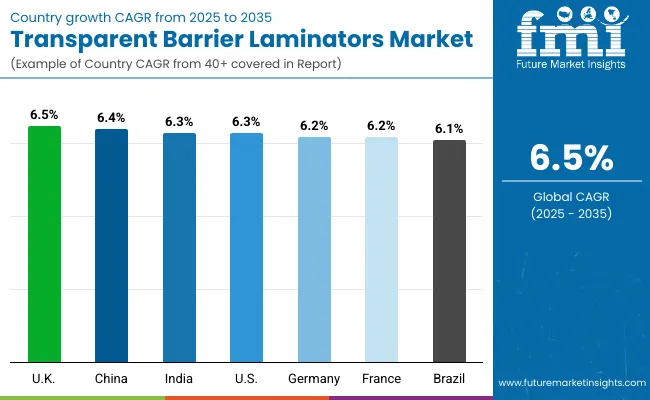

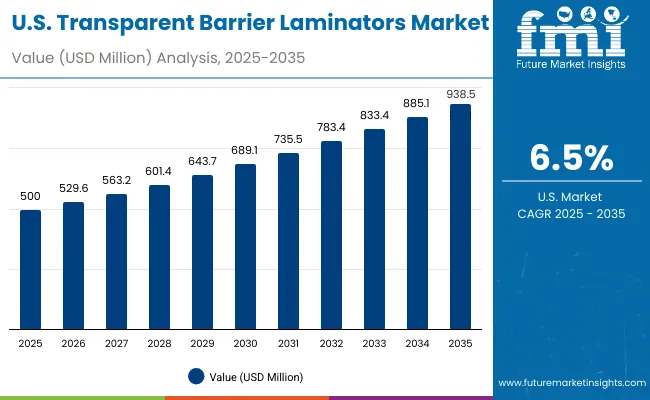

The USA market will grow at a CAGR of 6.5% from 2025 to 2035, driven by the expanding food and medical film packaging industries. Rising consumer demand for high-barrier transparent laminates is strengthening market growth. Packaging companies are investing in fully automated lamination lines to increase throughput and reduce material waste. Sustainability certifications and FDA-compliant materials are further driving innovation in solvent-free and recyclable lamination processes across major converters.

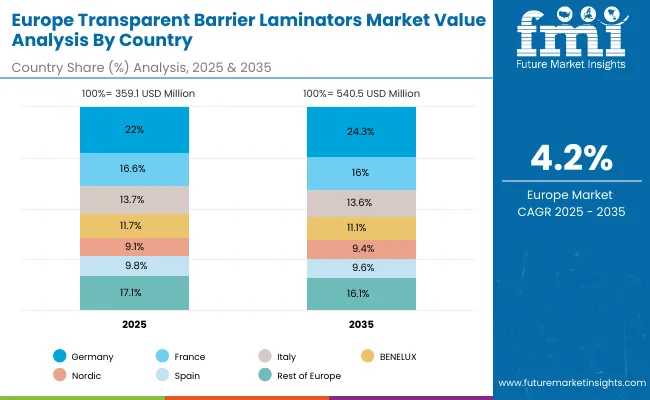

Germany will grow at a CAGR of 6.2%, supported by its leadership in advanced converting machinery and engineering. The growing need for precision lamination in pharmaceuticals and specialty packaging is spurring demand for hybrid laminators. German manufacturers are integrating advanced controls for VOC minimization and energy efficiency. EU-driven eco-design directives are enhancing Germany’s position as a global exporter of environmentally compliant lamination systems.

The UK market will grow at a CAGR of 6.3%, driven by expansion in consumer goods and e-commerce packaging. Transparent barrier laminates are increasingly replacing traditional opaque plastics for visual appeal and recyclability. Local converters are investing in flexible lamination technology that supports lower energy use and enhanced film bonding. The shift toward recycled barrier materials and sustainable adhesive systems is accelerating across the packaging industry.

China will grow at a CAGR of 6.4%, powered by expanding converter capacity and strong export potential. Local manufacturing is boosting PET and polypropylene-based film production for global distribution. The government’s focus on green manufacturing and circular packaging is accelerating investment in solvent-free lamination systems. Adoption of smart, digitally controlled laminators is enabling higher precision and reduced energy consumption in China’s rapidly advancing packaging sector.

India will grow at a CAGR of 6.3%, supported by food packaging modernization and regional expansion of lamination units. Demand for cost-effective PET and bio-based laminates is rising, particularly across FMCG and export packaging. The introduction of sustainability certifications and energy-efficient equipment is improving production quality. Local converters are adopting hybrid adhesive systems and recyclable multilayer laminates to meet global standards.

Japan will grow at a CAGR of 6.9%, emphasizing compact, automated laminators for high-precision applications. Integration of advanced coating and curing systems enhances film efficiency and output consistency. Hybrid adhesives with low VOC emissions are driving adoption in food and medical packaging. Japan’s strong engineering and robotics ecosystem continues to support innovation in lamination technology for high-barrier, sustainable packaging solutions.

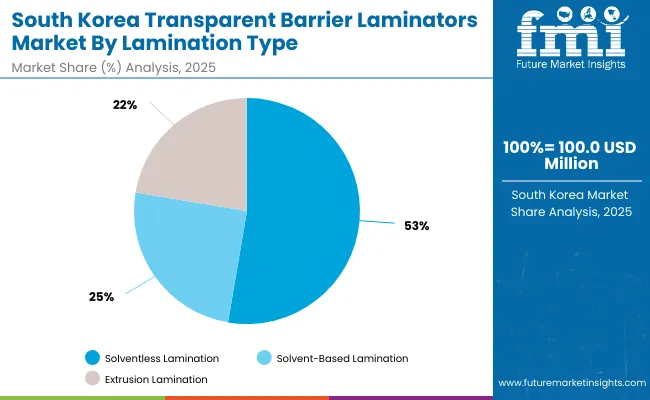

South Korea will lead with a CAGR of 7.0%, driven by rapid investments in flexible packaging and high-speed automation. Manufacturers are deploying smart laminators equipped with AI-driven control systems to enhance quality and production stability. Solvent-free adhesives and bio-based barrier films dominate new installations. Strategic partnerships with global technology firms are further expanding South Korea’s footprint in advanced lamination systems across international markets.

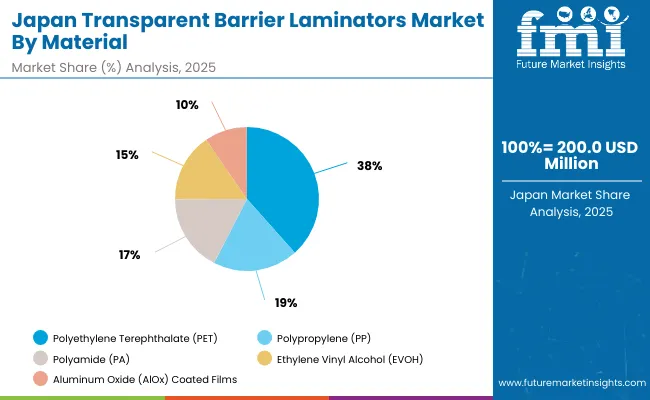

Japan’s transparent barrier laminators market, valued at USD 200.0 million in 2025, is led by polyethylene terephthalate (PET) films due to their high clarity, strength, and recyclability. Polypropylene (PP) laminates are expanding with increased use in flexible food packaging applications. Polyamide (PA) films offer superior puncture resistance, supporting demand in industrial and pharmaceutical packaging. Meanwhile, EVOH and aluminum oxide (Alox) coated films enhance gas and moisture barriers, strengthening Japan’s advanced multilayer packaging innovations.

South Korea’s transparent barrier laminators market, valued at USD 100.0 million in 2025, is dominated by solventless lamination, driven by sustainability regulations and reduced VOC emissions. Solvent-based lamination remains relevant for high-performance adhesive needs in food and medical packaging. Extrusion lamination is increasingly adopted for durable multilayer films offering enhanced mechanical strength. South Korea’s focus on eco-friendly manufacturing and flexible packaging innovation fuels steady expansion in advanced lamination technologies.

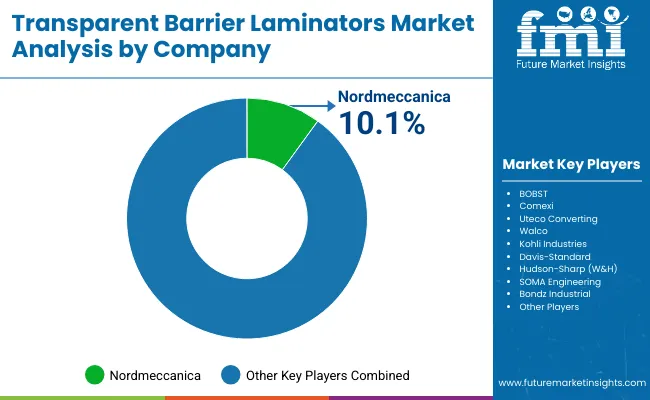

The market is moderately consolidated, featuring Nordmeccanica, BOBST, Comexi, Uteco Converting, Walco, Kohli Industries, Davis-Standard, Hudson-Sharp (W&H), SOMA Engineering, and Bondz Industrial.

Nordmeccanica and BOBST lead in global laminator sales, while Uteco and Comexi focus on high-speed, eco-efficient designs. SOMA and Kohli emphasize modularity and automation for mid-scale converters. Competition centers on precision, energy savings, and sustainable adhesives.

Key Developments of Transparent Barrier Laminators Market

| Item | Value |

|---|---|

| Quantitative Units | USD 1.5 Billion |

| By Material | PET, PP, PA, EVOH-Coated, AIOx -Coated Films |

| By Lamination Type | Solventless, Solvent-Based, Extrusion |

| By Application | Food, Blister Films, Electronics, Industrial Goods |

| Key Companies Profiled | Nordmeccanica , BOBST, Comexi , Uteco Converting, Walco , Kohli Industries, Davis-Standard, Hudson-Sharp (W&H), SOMA Engineering, Bondz Industrial |

| Additional Attributes | Growth driven by PET recyclability, solventless processing, and automation in packaging conversion. |

The market will be valued at USD 1.5 billion in 2025.

The market will reach USD 2.9 billion by 2035.

The market will grow at a CAGR of 6.5% during 2025-2035.

Solventless lamination will dominate with a 39.8% share in 2025.

Food packaging will anchor demand with a 36.5% share in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Transparent Paper Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Transparent Coating Market Size and Share Forecast Outlook 2025 to 2035

Transparent Plastics Market Size and Share Forecast Outlook 2025 to 2035

Transparent Conductive Films Market Size and Share Forecast Outlook 2025 to 2035

Transparent Plastic Packaging Market Size and Share Forecast Outlook 2025 to 2035

Transparent Ceramics Market Size and Share Forecast Outlook 2025 to 2035

Transparent Display Market Size and Share Forecast Outlook 2025 to 2035

Transparent Digital Signage Market Analysis by Type, End Users and Region Through 2035

Multilayer Transparent Conductors Market Size and Share Forecast Outlook 2025 to 2035

UV-Blocking Transparent Film Market Size and Share Forecast Outlook 2025 to 2035

Barrier System Market Forecast Outlook 2025 to 2035

Barrier Packaging Market Size and Share Forecast Outlook 2025 to 2035

Barrier Coated Papers Market Size and Share Forecast Outlook 2025 to 2035

Barrier Tube Packaging Market Size and Share Forecast Outlook 2025 to 2035

Barrier Resins Market Size and Share Forecast Outlook 2025 to 2035

Barrier Material Market Size and Share Forecast Outlook 2025 to 2035

Barrier Shrink Bags Market Analysis - Size, Share, and Forecast 2025 to 2035

Barrier Coated Paper Industry Analysis in Europe - Demand, Growth & Future Outlook 2025 to 2035

Key Players & Market Share in the Barrier Coated Paper Industry

Market Share Insights for Barrier Shrink Bag Providers

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA