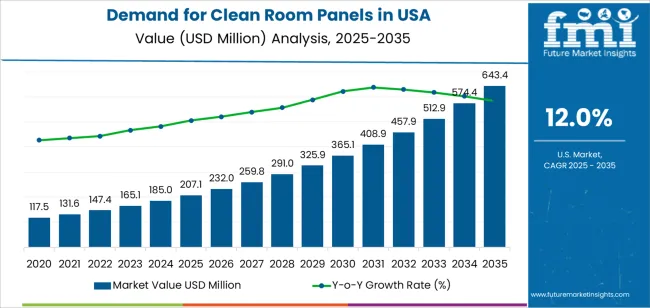

The demand for clean room panels in the USA is projected to reach USD 641.6 million by 2035, reflecting an absolute increase of USD 434.5 million over the forecast period. The demand, valued at USD 207.1 million in 2025, is expected to grow at a robust CAGR of 12%. This growth is primarily driven by the expanding need for controlled environments in industries such as pharmaceuticals, biotechnology, electronics, and aerospace, where clean room panels are crucial for maintaining sterile and contamination-free environments.

Clean room panels play an essential role in creating spaces that are free from dust, airborne microbes, and other contaminants that could affect sensitive processes, such as drug production, electronics manufacturing, and laboratory testing. As industries increasingly prioritize quality control, safety, and compliance with stringent regulations, the demand for these panels is expected to grow significantly. The rising focus on research and development, especially in life sciences and technology sectors, will further drive the demand for clean room solutions.

The demand is also supported by advancements in materials and technologies that improve the performance, durability, and cost-effectiveness of clean room panels. As industries continue to evolve, the need for more efficient and reliable clean room solutions will remain a key driver of growth.

The year-on-year (YoY) growth analysis for clean room panels in the USA reveals consistent and steady growth throughout the forecast period. Starting in 2025, the demand is valued at USD 207.1 million. In 2026, the demand rises to USD 231.9 million, reflecting an 11.3% increase. This growth accelerates slightly in the following years, with demand increasing by 12% annually. By 2027, the demand reaches USD 259.7 million, and by 2028, it grows to USD 290.8 million. In 2029, the demand continues to climb to USD 325.6 million, followed by a rise to USD 364.6 million by 2030. This steady growth, driven by expanding industries requiring controlled environments, highlights a sustained increase in demand.

From 2031 to 2035, the demand for clean room panels continues to rise steadily at a consistent growth rate of 12% each year. In 2031, demand reaches USD 408.2 million, and by 2032, it grows to USD 457.1 million. The upward trend continues with demand increasing to USD 511.8 million in 2033, USD 573.0 million in 2034, and finally, reaching USD 641.6 million in 2035. This YoY growth pattern reflects the ongoing expansion of sectors like pharmaceuticals, biotechnology, and electronics, all of which require clean room environments to meet regulatory standards and ensure product quality.

| Metric | Value |

|---|---|

| USA Clean Room Panels Sales Value (2025) | USD 207.1 million |

| USA Clean Room Panels Forecast Value (2035) | USD 641.6 million |

| USA Clean Room Panels Forecast CAGR (2025 to 2035) | 12.00% |

The demand in the USA for clean room panels is increasing as industries with strict contamination control requirements expand their production infrastructure. Key sectors such as pharmaceuticals, biotechnology, electronics, and semiconductors are driving the need for controlled environments capable of meeting stringent regulatory standards. Clean room panels offer the structural backbone for these controlled spaces, enabling firms to ensure high cleanliness levels, air purity, and the containment of particulates.

The surge in investment into biologics manufacturing, vaccine production, and advanced semiconductor fabrication in the USA is also a major factor. These applications require modular, high‑performance panel systems that can support rapid deployment and maintain integrity under demanding conditions. As companies scale up operations and retrofit existing facilities, clean room panels are becoming a critical component of infrastructure upgrades.

Technological enhancements in panel materials and formats such as antimicrobial surfaces, modular insert systems, and integration with environmental monitoring are further boosting demand. Firms are placing emphasis on flexibility, ease of installation, and compliance with international standards like ISO 14644. With these drivers in play, the demand for clean room panel systems in the USA is set to grow strongly over the next decade.

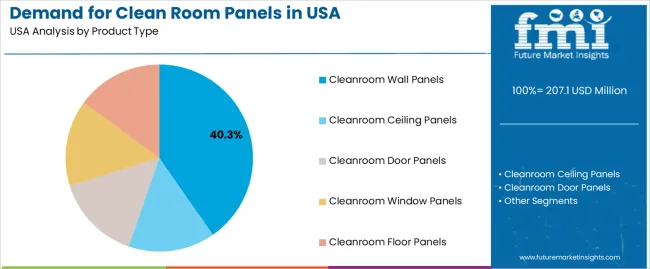

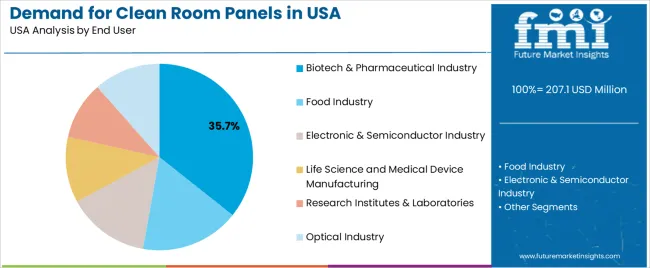

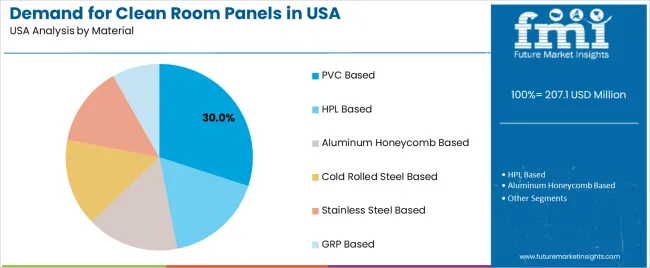

Demand is segmented by product type, end user, and material type. By product type, demand is divided into cleanroom wall panels, cleanroom ceiling panels, cleanroom door panels, cleanroom window panels, and cleanroom floor panels. Based on end user, demand is categorized into biotech & pharmaceutical industry, food industry, electronic & semiconductor industry, life science and medical device manufacturing, research institutes & laboratories, and optical industry. The industry is also segmented by material, including PVC based, HPL based, aluminum honeycomb based, cold rolled steel based, stainless steel based, and GRP based. Regionally, demand is divided into West, South, Northeast, and Midwest.

Cleanroom wall panels account for 40% of the demand for clean room panels in the USA. These panels are essential in creating the controlled environments required in industries like biotechnology, pharmaceuticals, and electronics manufacturing, where maintaining cleanliness and preventing contamination is crucial. Wall panels are the primary structural component in cleanrooms, offering durability, ease of installation, and seamless integration with other cleanroom components like doors and windows.

The growing demand for cleanroom wall panels is driven by the increasing need for sterile environments in sectors such as pharmaceuticals and electronics, where precision and hygiene are paramount. Cleanroom wall panels also provide excellent insulation properties and can be easily cleaned, which makes them ideal for maintaining air quality and preventing particle contamination. As industries expand their operations to meet increased demand for high-tech products, particularly in biotechnology, pharmaceuticals, and medical devices, the demand for cleanroom wall panels is expected to continue to grow, maintaining their dominant share in the industry.

The biotech & pharmaceutical industry represents 35.7% of the demand for clean room panels in the USA. Cleanrooms are critical in the production of pharmaceutical products and biotechnology research, where even minor contaminants can result in product failure or regulatory issues. The demand for cleanroom panels in this industry is driven by the stringent regulations and standards that require a controlled, contamination-free environment. Panels are used to create walls, ceilings, and floors that prevent particle contamination, ensuring the integrity of products such as vaccines, sterile drugs, and biotech innovations.

As the biotech and pharmaceutical sectors grow, driven by increased drug development, vaccine production, and personalized medicine, the need for advanced cleanroom infrastructure is expanding. Moreover, ongoing technological advancements in biopharmaceuticals and a growing focus on precision medicine also contribute to the rising demand for cleanroom panels. With more companies investing in state-of-the-art cleanroom facilities to meet regulatory and safety standards, the biotech & pharmaceutical industry is expected to continue leading the demand for clean room panels.

PVC-based material accounts for 30% of the demand for clean room panels in the USA. PVC is widely used in cleanroom construction due to its cost-effectiveness, durability, and ease of maintenance. It offers excellent resistance to corrosion, chemicals, and moisture, making it ideal for industries where cleanliness and chemical resistance are crucial, such as pharmaceuticals and electronics. PVC-based panels are also lightweight, easy to install, and can be easily cleaned to prevent particle buildup, ensuring the cleanliness and integrity of the cleanroom environment.

The preference for PVC-based materials is also driven by their versatility in different cleanroom applications, from walls to ceilings. In addition, PVC-based panels are highly customizable, allowing manufacturers to meet the specific needs of various industries. As demand for cleanroom environments grows, particularly in pharmaceutical, biotech, and electronics manufacturing, the adoption of PVC-based materials is expected to continue to rise. Its combination of affordability, durability, and ease of maintenance makes it a preferred choice for building and upgrading cleanroom facilities.

Clean‑room panels are essential for contamination‑control, modular clean‑room builds and retrofits to meet stricter regulatory standards and production volumes. Key drivers include increased investment in life‑sciences infrastructure, semiconductor fab expansion, and faster construction via modular systems. Restraints stem from the high upfront cost of specialty panels, complex retrofit installation in existing facilities, and supply‑chain challenges for advanced materials.

Why is Demand for Clean‑Room Panels Growing in USA?

Demand for clean‑room panels in the USA is growing as industries such as pharmaceuticals, biotechnology, and semiconductor manufacturing increasingly require clean, controlled environments to meet stringent regulatory standards. These panels offer a more efficient and cost‑effective alternative to traditional construction methods by enabling faster project timelines with prefabricated, modular systems. As demand for biologics, micro‑electronics, and advanced manufacturing increases, particularly in response to government initiatives and the need to boost national production capacity, the need for clean‑room infrastructure upgrades has risen. The ability of clean‑room panels to facilitate rapid expansion and adapt to changing regulatory requirements makes them an essential solution for maintaining competitive advantage in high‑growth sectors.

How Are Technological Innovations Driving Growth in USA?

Technological innovations are driving the growth of clean‑room panels in the USA by improving both performance and installation efficiency. New advancements in antimicrobial coatings and better joint sealing technologies enhance the panels' ability to prevent contamination. The development of composite materials with improved thermal and structural properties allows clean‑room panels to better withstand demanding environments. Modular panels now integrate utility channels directly into the system, simplifying construction and reducing the need for additional modifications. These innovations are particularly important in fast‑paced industries where quick installation and high reliability are critical. As a result, clean‑room panels are becoming increasingly popular in industries like pharmaceuticals, biotechnology, and semiconductors, where downtime and contamination risks must be minimized.

What are the Key Challenges Limiting the Uptake in USA?

Despite strong growth, the adoption of clean‑room panels in the USA faces several key challenges. The high initial capital investment required for premium panels, especially when combined with the full clean‑room setup, can deter smaller or budget-conscious businesses from upgrading. Retrofitting existing facilities to accommodate newer panel systems can be complex and costly, limiting adoption in older facilities. Supply chain volatility, particularly for specialty materials like composites or coatings, can delay production timelines and increase costs. The rapid evolution of clean‑room technologies requires ongoing investment in maintenance and upgrades, further adding to the cost burden. These barriers slow the broader adoption of clean‑room panels outside high‑growth segments, such as pharmaceuticals and high-tech manufacturing.

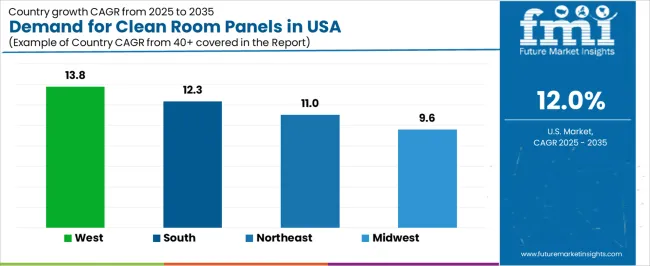

| Region | CAGR (%) |

|---|---|

| West | 13.8% |

| South | 12.3% |

| Northeast | 11.0% |

| Midwest | 9.6% |

The demand for clean room panels in the USA is experiencing strong growth, with the West leading at a 13.8% CAGR. This growth is primarily driven by the expanding pharmaceutical, biotechnology, and electronics industries that require clean room environments for manufacturing. The South follows at 12.3%, bolstered by significant investments in medical manufacturing and tech industries. The Northeast, with its established healthcare and life sciences sectors, shows a solid 11.0% CAGR. The Midwest, while growing at a slower pace with a 9.6% CAGR, benefits from ongoing industrial modernization and advancements in high-tech manufacturing.

The West is leading the demand for clean room panels in the USA, with a 13.8% CAGR. The region’s significant role in biotechnology, pharmaceuticals, and electronics manufacturing, which all require clean rooms for production and research, is a key driver. Major cities like San Francisco, San Diego, and Los Angeles are centers for life sciences and tech industries that rely on advanced clean room environments to maintain strict contamination control standards.

The West’s emphasis on cutting-edge technology, innovation, and the expansion of medical device manufacturing has significantly boosted the demand for clean room panels. As industries scale up and focus on maintaining air quality control and ensuring contamination-free environments, the need for clean rooms becomes even more critical. As the demand for advanced manufacturing processes continues to rise, the West’s growth in clean room panel adoption is expected to remain strong. With its continued focus on technological advancements and high-quality production standards, the West is likely to maintain its position as the leader in clean room panel adoption across the country.

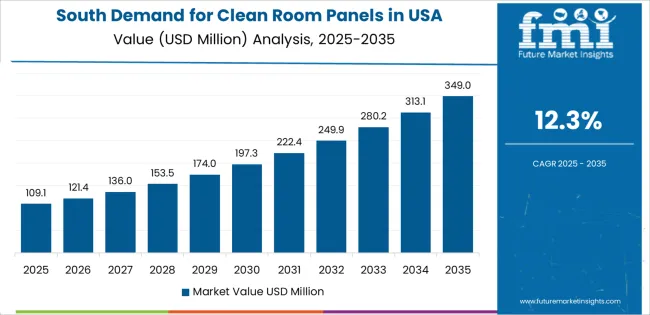

The South is experiencing robust growth in demand for clean room panels, with a 12.3% CAGR. This is driven by the expansion of pharmaceutical, biotechnology, and semiconductor industries in states like Texas, Florida, and Georgia. As these sectors continue to grow, there is an increasing need for clean room environments that ensure precise control over air quality and contamination levels during manufacturing and research processes.

The rise of medical device manufacturing and the burgeoning tech industry in the South also plays a major role in driving demand for clean room panels. These industries require strict environmental controls to ensure product quality and safety. Ongoing investments in infrastructure and the establishment of new research and production facilities have contributed to a steady increase in demand for clean room solutions in the region. As more companies in the South embrace advanced manufacturing techniques and high standards for environmental control, the region’s demand for clean room panels is expected to continue growing at a strong pace.

The Northeast is experiencing steady demand growth for clean room panels, with an 11.0% CAGR. The region is home to major pharmaceutical companies, research institutions, and medical device manufacturers that rely on clean rooms to ensure product integrity and maintain controlled environments during the production and research stages. Key cities like Boston, New York, and Philadelphia are hubs for life sciences and healthcare, creating a strong demand for clean room solutions.

As industries in the Northeast continue to innovate, the need for high-quality clean room environments that prevent contamination and ensure product safety grows. The region’s established infrastructure, which supports advanced research and manufacturing, is a key factor driving the increased demand for clean room panels. Moreover, with ongoing investments in the healthcare and life sciences sectors, the Northeast’s clean room panel industry is expected to remain robust. The growing trend toward specialized medical treatments and pharmaceutical production will likely keep the region at the forefront of clean room panel adoption.

The Midwest is experiencing moderate growth in demand for clean room panels, with a 9.6% CAGR. The region is home to a strong industrial base, with major industries like automotive, electronics, and food production increasingly adopting clean room technology. Cities such as Chicago, Detroit, and Indianapolis are becoming key centers for manufacturing and high-tech industries, all of which are demanding stricter environmental controls for quality assurance and product integrity.

While growth in the Midwest is slower than in other regions, industries like medical device manufacturing, industrial automation, and pharmaceuticals are driving steady demand for clean room panels. Companies in the Midwest are increasingly investing in advanced manufacturing techniques that prioritize air quality and contamination control, boosting the need for specialized clean room environments. As the region continues to modernize its manufacturing practices and adopt higher standards for environmental control, the demand for clean room panels will continue to grow at a steady, albeit more moderate, pace.

The demand for clean‑room panels in the United States is strengthening significantly, driven by intensive expansion in industries requiring controlled‑environment facilities—such as pharmaceuticals, biotech manufacturing, semiconductor fabrication, and medical device production. Clean‑room panels play a crucial role in creating contamination‑controlled spaces where strict standards for particle counts, air purity, and cleanliness are required. As USA firms invest in new or upgraded clean‑room infrastructure and modular systems for fast build‑outs, demand for high‑performance panel systems continue to rise.

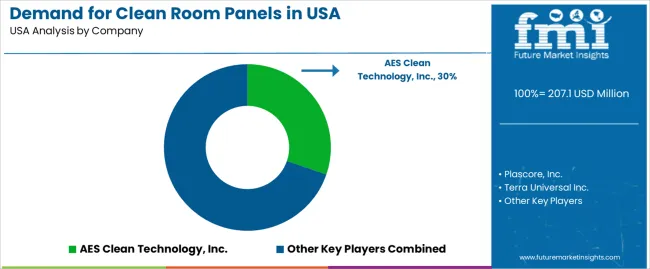

Within the USA demand landscape, AES Clean Technology, Inc. commands approximately 30.3% of the demand, reflecting its strong reputation, broad product range and customer base for clean‑room panel solutions tailored to American regulatory and operational needs. Other notable companies contributing to demand include Plascore, Inc., Terra Universal Inc., G‑CON Manufacturing, and Pacific Panels Inc., each supplying panel materials and modular systems that meet strict USA clean‑room requirements and customer expectations.

Key drivers fueling this demand include the growth in pharmaceutical and biotech production facilities, rapid expansion of semiconductor manufacturing in the USA, heightened regulatory focus on contamination control, and adoption of modular clean‑room construction that shortens lead times and reduces cost. Challenges like high upfront installation costs, complex retrofit requirements in existing facilities, and material supply‑chain pressures remain. Nonetheless, the outlook remains robust as manufacturers continue embracing advanced clean‑room panel solutions to align with stringent productivity, quality and compliance demands.

| Items | Values |

|---|---|

| Quantitative Unit | USD million |

| Product Type | Cleanroom Wall Panels, Cleanroom Ceiling Panels, Cleanroom Door Panels, Cleanroom Window Panels, Cleanroom Floor Panels |

| End User | Biotech & Pharmaceutical Industry, Food Industry, Electronic & Semiconductor Industry, Life Science and Medical Device Manufacturing, Research Institutes & Laboratories, Optical Industry |

| Material | PVC Based, HPL Based, Aluminum Honeycomb Based, Cold Rolled Steel Based, Stainless Steel Based, GRP Based |

| Regions Covered | West, South, Northeast, Midwest |

| Key Players Profiled | AES Clean Technology, Inc., Plascore, Inc., Terra Universal Inc., G-CON Manufacturing, Pacific Panels Inc. |

| Additional Attributes | Dollar sales by product type, end user, material, and regional trends |

The global demand for clean room panels in USA is estimated to be valued at USD 207.1 million in 2025.

The market size for the demand for clean room panels in USA is projected to reach USD 643.4 million by 2035.

The demand for clean room panels in USA is expected to grow at a 12.0% CAGR between 2025 and 2035.

The key product types in demand for clean room panels in USA are cleanroom wall panels, cleanroom ceiling panels, cleanroom door panels, cleanroom window panels and cleanroom floor panels.

In terms of end user, biotech & pharmaceutical industry segment to command 35.7% share in the demand for clean room panels in USA in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Demand Signal Repository Solutions Market Size and Share Forecast Outlook 2025 to 2035

Demand Side Management Market Size and Share Forecast Outlook 2025 to 2035

Demand Response Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

North America Shipping Supplies Market Trends – Innovations & Growth 2024-2034

Demand of Kozani Saffron in Greece Analysis - Size, Share & Forecast 2025 to 2035

Demand of No-acid Whey Strained Dairy Processing Concepts in European Union Size and Share Forecast Outlook 2025 to 2035

Demand for Bronte Pistachio in Italy Analysis - Size, Share & Forecast 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Western Europe Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Japan Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Korea Size and Share Forecast Outlook 2025 to 2035

Glycine Soja (Soybean) Seed Extract Market Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Yeast in Japan - Size, Share, and Forecast Outlook 2025 to 2035

Demand and Trends Analysis of Stevia in Japan Size and Share Forecast Outlook 2025 to 2035

Demand of Pistachio-based desserts & ingredients in France Analysis - Size, Share & Forecast 2025 to 2035

Japan Women’s Intimate Care Market Trends – Growth & Forecast 2024-2034

Western Europe Men’s Skincare Market Analysis – Forecast 2023-2033

Demand and Trend Analysis of Fabric Stain Remover in Korea Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Japan Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Korea Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Western Europe Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA