The wire harness tape market is experiencing steady growth driven by expanding automotive production, advancements in electrical systems, and the need for enhanced insulation and protection in wiring applications. Rising vehicle electrification and integration of advanced safety and infotainment systems are creating consistent demand for high-performance tapes. Market players are focusing on developing heat-resistant, flame-retardant, and durable materials to meet evolving performance and safety standards.

Growing emphasis on noise reduction, vibration control, and space optimization within vehicles is further supporting market expansion. The future outlook remains positive as regulatory bodies continue to mandate stringent electrical safety and emission standards.

Emerging opportunities in electric vehicles and renewable energy applications are expected to widen the adoption of specialized harness tapes Strategic investment in material innovation, adhesive technology, and sustainable production practices will continue to define competitive positioning, ensuring steady revenue growth and broader market penetration across industrial and automotive applications.

| Metric | Value |

|---|---|

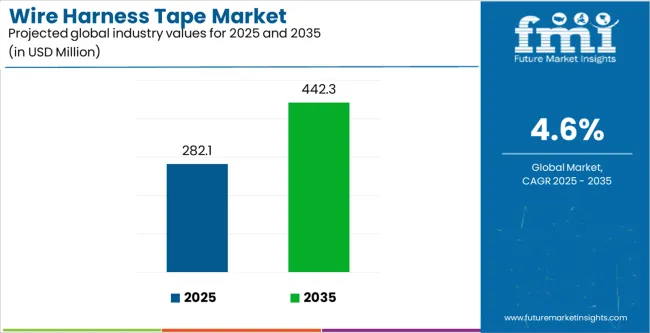

| Wire Harness Tape Market Estimated Value in (2025 E) | USD 282.1 million |

| Wire Harness Tape Market Forecast Value in (2035 F) | USD 442.3 million |

| Forecast CAGR (2025 to 2035) | 4.6% |

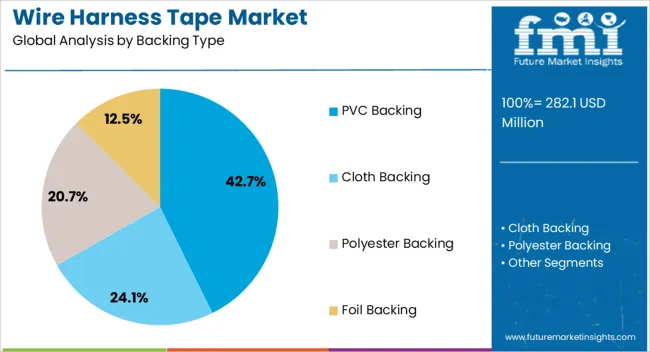

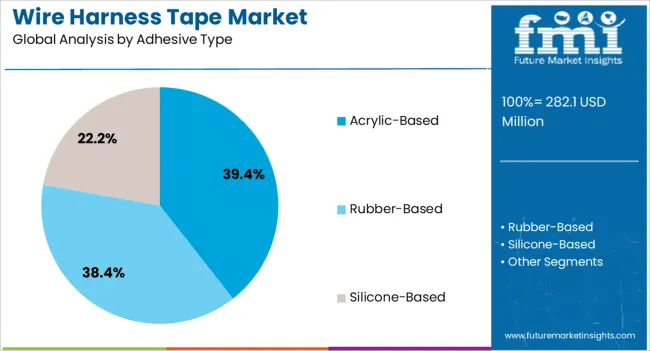

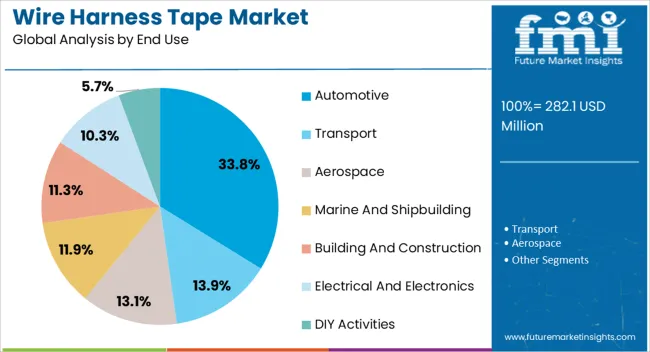

The market is segmented by Backing Type, Adhesive Type, and End Use and region. By Backing Type, the market is divided into PVC Backing, Cloth Backing, Polyester Backing, and Foil Backing. In terms of Adhesive Type, the market is classified into Acrylic-Based, Rubber-Based, and Silicone-Based. Based on End Use, the market is segmented into Automotive, Transport, Aerospace, Marine And Shipbuilding, Building And Construction, Electrical And Electronics, and DIY Activities. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The PVC backing segment, accounting for 42.70% of the backing type category, has maintained its dominance due to superior flexibility, electrical insulation, and cost-effectiveness. Its wide applicability across automotive wiring, industrial machinery, and consumer electronics has reinforced its market position.

The segment benefits from high temperature and abrasion resistance, which ensures reliable performance under harsh operational conditions. Consistent demand from automotive OEMs and component suppliers has supported production stability.

Manufacturers are investing in eco-friendly formulations to meet evolving environmental standards, further strengthening long-term growth prospects Continuous improvements in processing efficiency and adhesive compatibility are enhancing product performance, ensuring that PVC-backed tapes remain a preferred choice in wire harnessing applications across multiple end-use sectors.

The acrylic-based adhesive segment, holding 39.40% of the adhesive type category, has emerged as the leading formulation due to its superior adhesion, temperature resistance, and long-term stability. Its compatibility with various backing materials and substrates makes it suitable for high-demand applications in automotive and industrial environments.

The segment’s growth is supported by the trend toward lightweight and durable adhesive systems that ensure reliable bonding under thermal and mechanical stress. Advances in solvent-free and low-VOC formulations are enhancing environmental compliance, while improved adhesion to plastics and metals is expanding use across complex assemblies.

Continuous research into performance optimization and material sustainability is expected to maintain the competitive edge of acrylic-based adhesives and sustain their leadership in wire harness tape production.

The automotive segment, representing 33.80% of the end-use category, remains the primary consumer of wire harness tapes due to extensive wiring requirements in vehicle assembly and component integration. Increasing electrification, safety system installation, and the rise of electric and hybrid vehicles are driving consistent demand.

OEMs prioritize tapes offering high durability, noise suppression, and flame-retardant properties to ensure reliability and compliance with international standards. Expansion of vehicle production in Asia-Pacific and technological advancements in wiring design are reinforcing the segment’s growth.

Strategic sourcing partnerships and product customization are enabling manufacturers to meet OEM-specific needs efficiently With continued innovations in lightweight materials and thermal-resistant adhesives, the automotive segment is expected to sustain its leading share and drive long-term growth in the global wire harness tape market.

Rise in the Demand for Electronic Vehicles

The automotive wire harness tape market is experiencing growth due to the rising demand for automotive wire harness tape for various applications such as the car interior, engine compartment, dashboard, floor, airbags, seat belts, and others on a global scale. One notable trend in the wire harness tape market is its increasing use in the production of electric vehicles.

As per the analysis of wire harness tape materials for durability and insulation, the tapes are ideal for the production of automobiles with multiple electronic circuits. The key players in the wire harness tape industry are developing novel tapes with different materials and adhesives according to the applications of the tapes in the production process of the electronic vehicles industry.

Trend of Car Customization

The current customer base primarily comprises millennials, with GenZ gaining traction in the realm of vehicle customization. Enthusiasts are driving innovation in engine, wiring, and interior enhancements for automobiles. The integration of wire harness tape in automotive wire harness assemblies presents an attractive prospect for vehicle customization. More youthful consumers are revitalizing vintage cars, imbuing them with a dynamic and futuristic appeal. The evolution of custom exterior and interior designs for vehicles underscores the growth in the market for wire harness tapes.

To sum up, in contemporary automobile wiring systems, wire harness tapes are essential. Car designers and developers rely on wire harness tapes to help them stay competitive in a difficult market by providing binding protection, organization, and efficiency benefits.

Inflating Raw Material Price and Chances of Electronic Failure to Hamper Adoption

The wire harness tape market is expected to be hindered by volatility in raw material prices. Along with that, the wiring harness failures in automobiles can cause electrical issues, causing battery, lights, alternator, non-functional lights, and ignition failure. Such concerns can also cause the harness to bend, reducing its lifespan and causing further damage.

The adoption of wire harness tapes aids in bundling and organizing wires and cables, making installation and maintenance easier. The demand for electronic devices and reliable connections is anticipated to propel the demand for wire harness tapes in the period of 2020 to 2025.

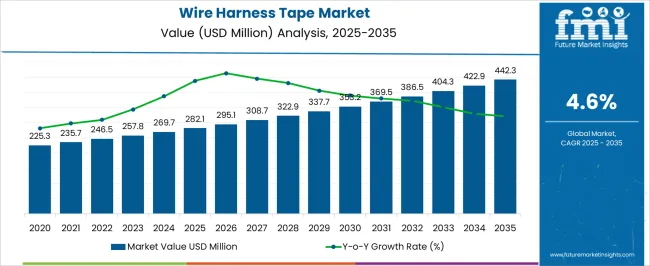

The industry in the period between 2020 to 2025 exhibited a CAGR of 3.3%. During the period of the pandemic, the sales of wire harness tapes were impacted due to the partial production of electronic vehicles and electronic gadgets. Subsequently, the demand for wire harness tapes has shown restricted applications in these sectors for a limited period. During the historical period and generated a market value of USD 282.1 million in 2025 from base valuation of USD 225.3 million in 2020.

The environmental sustainability considerations in wire harness tape production are augmenting the automobile production segment. The demand for plastic wire harness tape is developing in the early period of 2025 from the electronic vehicle industry. The growth factors influencing the wire harness tape market in the forecast period of 2025 to 2025 are the growing applications of electronic circuitry in several sectors.

The aerospace sector has also developed the demand for automotive wire harness tapes in the designing and assembly of spacecraft and aircraft. The lightweight nature and cost-effectiveness of wire harness tapes are also anticipated to push the demand during the evaluation period.

The wire harness tape sector is augmenting the demand based on various factors across the globe. In 2025, on the basis of adhesive type, rubber-based tapes are in demand, whereas the electrical and electronics industry is developing a larger consumer base for wire harness tapes.

The majority of the general population shows a strong preference for rubber-based wire harness tapes. It is projected that in 2025, these types of adhesive will account for 49.3% of the revenue share in the global market.

| Segment | Rubber-based (Adhesive Type) |

|---|---|

| Value Share (2025) | 49.3% |

Rubber, vinyl, electrical tape, conduit, or a blend of these materials are used to bind wires together in a wiring harness, which is an arrangement of cables used to carry electrical power or messages.

The demand for rubber-based adhesives is projected to experience a significant surge within the wire harness tape industry. This type of tape is widely utilized across various sectors for diverse purposes, such as insulation, protection against abrasion, and resistance to moisture. As a result, the need for rubber-based wire harness tape is anticipated to exhibit rapid growth over the forecast period.

On account of end use, the wire harness tapes industry is applied in multiple sectors. Among these, the electrical and electronics segment holds an industry share of 34.1% in 2025.

| Segment | Electrical and Electronics (End Use) |

|---|---|

| Value Share (2025) | 34.1% |

The increasing demand for electrical and electronic devices is a key aspect of the growth of the automotive wiring harness market. The expanding electrical and electronics industry is also foreseen to boost the demand for wire harness tapes, which are widely used for insulation, abrasion resistance, and moisture resistance in various applications.

Hence, the wire harness tape market is anticipated to experience rapid growth in the forecast period. The growing demand for electric vehicles (EVs) in developing regions is projected further to accelerate the market expansion within the specified time frame.

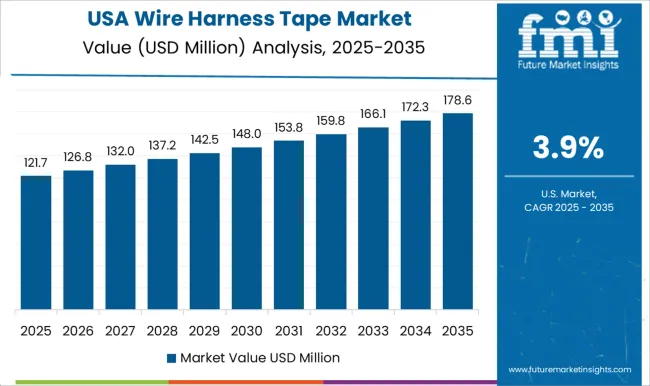

The section discusses the region-wise analysis of the wire harness tape industry. Information on key countries in several parts of the globe, including North America, Asia Pacific, Europe, and others, is provided. The United States is anticipated to remain at the forefront in North America, with a CAGR of 2.9% through 2035. In South Asia and Pacific, India is projected to witness a CAGR of 6.7% by 2035, leaving behind China at 5.9%.

| Countries | CAGR 2025 to 2035 |

|---|---|

| United States | 2.9% |

| Canada | 2.6% |

| United Kingdom | 2.8% |

| Germany | 2.4% |

| China | 5.9% |

| India | 6.7% |

The Indian wire harness tape industry is very likely to exhibit a healthy CAGR of 6.7% through 2035. Because of foreign producers, products are quite popular in the Indian market. India can provide resources and a large consumer base to the telecom business as a growing nation. The nation's technological developments are at an all-time high, enabling the sector to push limits.

More and more Indian enterprises are involved in the construction of underwater communication cables; the majority of these marine cables are being stretched across oceans. According to the National Maritime Foundation, there are four more proposed cable additions throughout the nation's maritime range. The wire harness tape sector may find new prospects as a result of the expansion of communication cables, which are utilized by wire harness tapes, in India.

China is also one of the most prominent countries when it comes to the wire harness tape industry. It is very likely to register a CAGR of 5.9% through 2035. China, the world's largest manufacturer in various industries, is dominated by its low labor cost and advanced innovation and technology, making it the preferred manufacturing hub globally.

China is the world's top producer of silicon, owing to its skilled labor force and strong supply chain. This dominance in silicon manufacturing will ease production in the wire harness tapes sector, as easy availability of adhesive strengthens manufacturers' production capacity. As such, Chinese industries are envisioned to propel growth in the market for wire harness tapes.

The United States wire harness tape industry is slated to show a 2.9% CAGR for the forecast period of 2025 to 2035. The United States boasts one of the world's largest automotive markets. As the demand for electric vehicles continues to rise in the country, there is a growing need for wire harness tapes.

Market players in the automobile industry are innovating and creating new applications for plastic wire harness tapes in the manufacturing of various car components such as car interiors, engine compartments, dashboards, floors, airbags, seat belts, and others. The advancement in car manufacturing in the United States is heavily reliant on cutting-edge research and development in the wire harness tape industry.

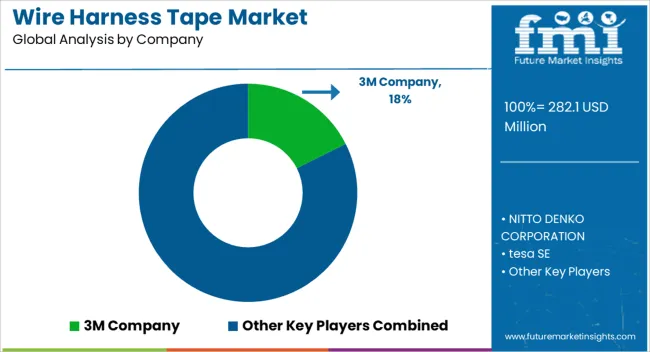

Key players in the wire harness tape industry are focusing on creating cutting-edge goods from environmentally friendly and sustainable materials. Top manufacturers will be able to meet strict environmental laws in addition to increasing sales in the automobile and aerospace industries.

Enterprises are always coming up with new wire harness tapes that have better properties, such as increased heat resistance, chemical resistance, and strength, to meet the various demands of various automotive and electronics applications.

In order to fulfill the demand, major companies in the wire harness tape industry are improving their skills with the goal of boosting sales and income, augmenting the market size of wire harness tapes. A few of the major firms are using the acquisition method in an attempt to raise resources. In order to satisfy the strong demand from customers, they are also launching new products. The companies are also focusing on modernizing their facilities in order to increase their production capabilities.

Industry Updates

In November 2025, New York-based Saint-Gobain Tape Solutions introduced new automotive assembly technologies, including Norbond Z2000 acrylic tapes, ensuring long-lasting adhesion for complex surfaces.

In 2025, Yongle Tape, headquartered in China, introduced a new line of eco-friendly wire harness tapes aimed at reducing environmental impact.

The market is segmented by backing type, with options including PVC backing, cloth backing, polyester backing, and foil backing.

In terms of adhesive type, the market is trifurcated into acrylic-based, rubber-based, and silicone-based.

Based on end use of tapes, the industries such as automotive, transport, aerospace, marine and shipbuilding, building and construction, electrical and electronics, and DIY activities gains the upper hand.

As per region, the industry is divided into North America, Latin America, Europe, Asia-Pacific, and the Middle East and Africa.

The global wire harness tape market is estimated to be valued at USD 282.1 million in 2025.

The market size for the wire harness tape market is projected to reach USD 442.3 million by 2035.

The wire harness tape market is expected to grow at a 4.6% CAGR between 2025 and 2035.

The key product types in wire harness tape market are pvc backing, cloth backing, polyester backing and foil backing.

In terms of adhesive type, acrylic-based segment to command 39.4% share in the wire harness tape market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Wire and Cable Management Market Forecast Outlook 2025 to 2035

Wire Rope Lubricants Market Size and Share Forecast Outlook 2025 to 2035

Wireless Access Point Market Size and Share Forecast Outlook 2025 to 2035

Wirewound Resistor Market Size and Share Forecast Outlook 2025 to 2035

Wire-cutting EDM Machines Market Size and Share Forecast Outlook 2025 to 2035

Wireless Video - 2.4/5GHz Market Size and Share Forecast Outlook 2025 to 2035

Wireless Polysomnography Market Size and Share Forecast Outlook 2025 to 2035

Wireless Audio Devices Market Size and Share Forecast Outlook 2025 to 2035

Wireless Communication Technologies In Healthcare Market Size and Share Forecast Outlook 2025 to 2035

Wireless Mesh Network Market Size and Share Forecast Outlook 2025 to 2035

Wireless Sensor Tags Market Size and Share Forecast Outlook 2025 to 2035

Wireless Sensor Network Market Size and Share Forecast Outlook 2025 to 2035

Wireless Power Transmission Market Size and Share Forecast Outlook 2025 to 2035

Wireless Home Security Camera Market Size and Share Forecast Outlook 2025 to 2035

Wire Livestock Panels Market Size and Share Forecast Outlook 2025 to 2035

Wireless Testing Market Size and Share Forecast Outlook 2025 to 2035

Wireless Power Bank Market Size and Share Forecast Outlook 2025 to 2035

Wireless Battery Monitoring System Market Size and Share Forecast Outlook 2025 to 2035

Wire and Cable Market Size and Share Forecast Outlook 2025 to 2035

Wireless Printer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA