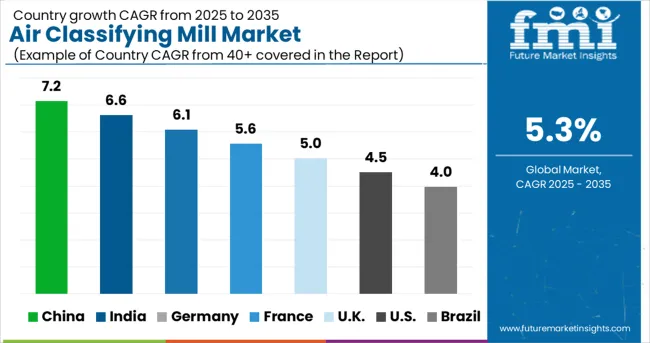

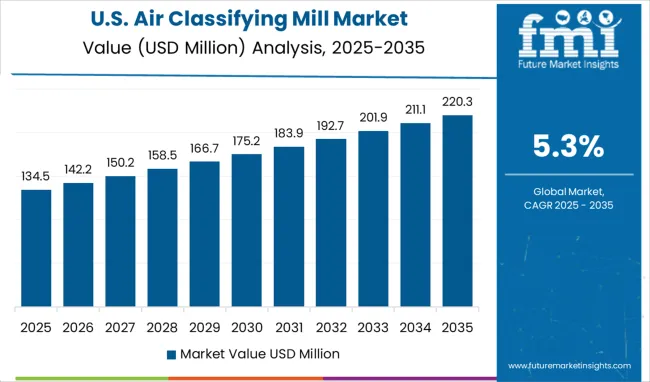

The Air Classifying Mill Market is estimated to be valued at USD 1096.8 million in 2025 and is projected to reach USD 1838.3 million by 2035, registering a compound annual growth rate (CAGR) of 5.3% over the forecast period.

The air classifying mill market is witnessing consistent growth as industries increasingly prioritize precision milling, energy efficiency, and product quality enhancement. Rising demand for finely milled powders in food processing, pharmaceuticals, and chemicals has positioned these mills as an indispensable part of modern production facilities.

Companies are focusing on integrating energy-efficient designs and advanced control systems to meet stringent quality and safety standards, thereby supporting market expansion. Growth is also being driven by operational benefits such as reduced contamination, ease of cleaning, and flexible particle size distribution which have become crucial under evolving regulatory and competitive environments

Future opportunities are anticipated to stem from innovations in wear-resistant materials, automation integration, and expansion of applications into emerging sectors requiring high purity and consistent particle sizes, paving the way for sustained market adoption.

The market is segmented by Type, Application, and Sales Channel and region. By Type, the market is divided into Horizontal Mills, Vertical Mills, and Circular Mills. In terms of Application, the market is classified into Food Processing, Pharmaceuticals, Cosmetics, and Others. Based on Sales Channel, the market is segmented into Offline and Online. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The market is segmented by Type, Application, and Sales Channel and region. By Type, the market is divided into Horizontal Mills, Vertical Mills, and Circular Mills. In terms of Application, the market is classified into Food Processing, Pharmaceuticals, Cosmetics, and Others. Based on Sales Channel, the market is segmented into Offline and Online. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

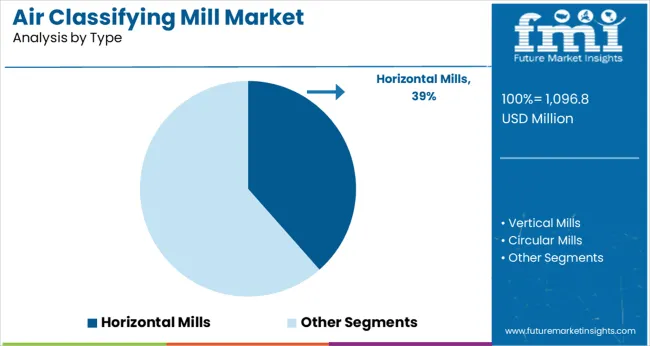

When segmented by type, horizontal mills are expected to account for 38.5% of the total market revenue in 2025, establishing themselves as the leading type segment. This dominance has been attributed to their compact design, superior efficiency in handling fine and ultra-fine powders, and their ability to maintain uniform particle size distribution.

Horizontal configurations have facilitated easier integration into existing production lines due to their space-saving footprint and have enhanced operational stability, especially in continuous processing environments. Durability and lower maintenance requirements have further strengthened their appeal among end users seeking cost effective, high-performance solutions.

The versatility offered by horizontal mills in accommodating a wide range of materials while maintaining product integrity has positioned this segment at the forefront of adoption.

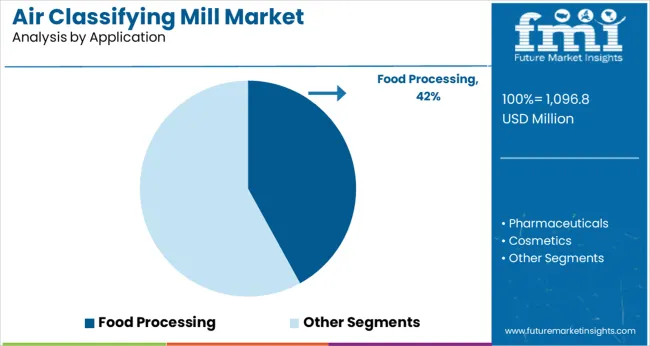

In terms of application, food processing is projected to hold 42.0% of the market revenue share in 2025, making it the leading application segment. This leadership has been driven by increasing demand for precisely milled ingredients required for bakery products, spices, nutritional supplements, and specialty flours.

Air classifying mills have become critical in maintaining hygiene standards, ensuring consistent texture, and achieving the desired particle size without generating excessive heat which can degrade sensitive ingredients. Food producers have increasingly favored these mills for their ability to comply with stringent food safety regulations while delivering high throughput.

The segment’s growth has also been reinforced by the expanding global processed food industry and rising consumer preferences for premium, uniform, and safe food products, further consolidating its dominance.

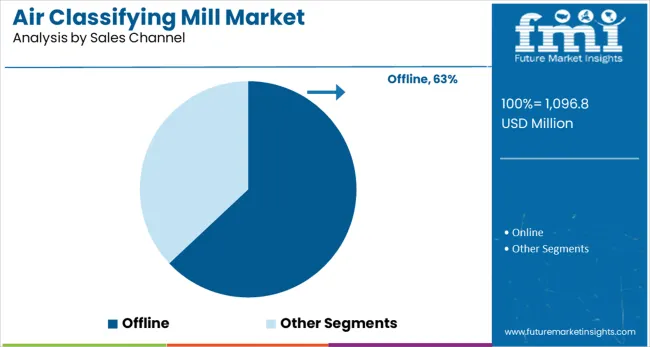

Segmenting by sales channel shows that offline sales are anticipated to contribute 63.0% of the market revenue in 2025, maintaining their leadership as the preferred distribution channel. This dominance has been supported by the complex and customized nature of air classifying mills, which necessitates in-person consultation, demonstrations, and tailored solutions that are best delivered through offline channels.

Purchasing decisions for such capital-intensive equipment often involve direct negotiations, site visits, and technical support, which have continued to favor offline interactions. End users have shown a strong preference for engaging with experienced sales representatives and service engineers to ensure proper installation, training, and maintenance support.

The established networks of distributors and regional agents have further enabled easier access, faster response times, and enhanced customer confidence, sustaining offline channels as the primary conduit for sales.

Air Classifying Mill Market Historical Outlook shows that the market's value expanded from USD 847.2 million in 2020 to USD 1096.8 million in 2025. The observed CAGR (2020 to 2025) is 3.8%.

The Air Classifying Mill market is growing rapidly as the demand for these products increases. The main drivers of this growth are the increasing demand for air classification in industries such as food processing, pharmaceuticals, and cosmetics. Additionally, the Air Classifying Mill market is also driven by the rising awareness of the benefits of these products among consumers.

Air Classifying Mill market value climbed from USD 1096.8 million in 2025 to USD 1,657.9 million in 2035 according to future projections. 5.3% CAGR is predicted to occur between 2025 and 2035.

Horizontal - By Product Type

Food Processing Industry - By End User Industry Type

North America is the leading air classifying mill market, growing at a CAGR of 32.8%. This is attributed to the increasing demand for these mills from the manufacturing and processing industries. Moreover, the air classifying mill market is also being driven by the rising number of applications for these mills in various industries.

Key players in the USA provide mills that operate using the combination of two-stage close-circuit grinding/milling with an inter-stage air classifier all in one convenient unit. In addition, the internal air classifier continuously recirculates particles that are larger than desired back into the grinding zone ensuring an optimal final product particle size. This is likely to aid in the strong-paced growth of the air classifying mill market share in the coming years.

There are several features that are offered by the key manufacturers of air classifying mills in this region, that are remarkably favorable for end users. For instance, the mills are capable to grind challenging materials. Moreover, narrow particle size distribution is made easy, which is also highly uniform. These mills are high in demand since they require minimal and quick maintenance.

End users in the USA require an air classifying mill that can be designed for grinding hygroscopic, heat sensitive, and explosive materials in inert gas/closed loop systems with dry chilled air. Therefore, key players strive to offer these features with integrated grinding, classifying, conveying, and collecting operations for achieving ultra-fine grinding (up to 2 microns) depending upon the nature of the product. This is expected to drive the adoption of air classifying mills amongst American customers.

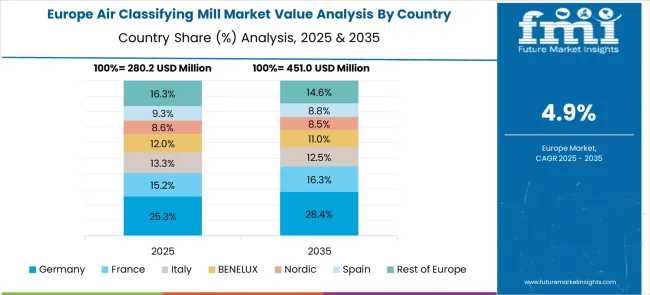

With a notable CAGR of 26.7%, Europe holds the second-largest share of the air classifying mill market, with Germany being the most profitable market. On the other hand, the United Kingdom holds a revenue share of 6% over the projection period. This is attributed to the growing demand for these mills in the food processing industry.

The demand for air classifying mills is rising in Germany, essentially owing to their use to grind various food products, such as spices, coffee beans, and grains. Moreover, they are also used in the pharmaceutical industry for grinding various active ingredients and excipients. This is likely to support the expansion of the global market size.

Increasing industrialization and urbanization in European countries are resulting in the increased demand for air classifying mills from various industries such as chemicals, minerals, and others. Furthermore, key players in Germany offer mills that can be operated with ambient air, hot air as well as dried and cooled air which covers a wide range of mineral applications.

The Asia Pacific is a lucrative air classifying mill market with China and India as the market leaders with revenue shares of 6.6% and 6.2%, respectively. The rapidly expanding market in this region is owing to the growing demand for these products in the region. It is essentially used in the food processing industry, as well as pharmaceutical and cosmetics industries.

China is primarily responsible for exporting machine components to key market players in developed countries. However, the country also benefits from the adoption of air classifying mills owing to its proliferating food and beverage industry. Additionally, the mills provided by the market players in this country are ideal for difficult-to-grind applications or narrow particle distribution curve requirements and offer simple maintenance, uniform particle distribution, a screen-less frame that prevents screen damage and wear.

Safety is always a first for key companies when it comes to air classifying mills so that they are suitable for beginners and accidents or injuries are reduced. Hence, the mills and fine grinders are equipped with an automatic door-locking device to prevent accidental access to the inside while the rotor is operating. In addition, a secondary inlet to provide additional air for an element of cooling is also equipped within these machines.

India has one of the largest food and beverage and pharmaceutical industries in the world and requires the adoption of air classifying mills for grinding food and medicines. The market is growing at a rapid pace and the regional market players sometimes engage in collaborations with key market players in developed countries.

Key players manufacture and supply all types of air classifier mills with food grades of stainless steel material and are designed in accordance with various industrial standards. Moreover, they bring clients air classifying mills of exceptional quality at cost-effective prices. These are likely to contribute to global market growth.

The mills offered by the key players in the country are able to reject coarse material requiring further size reduction which occurs entirely inside the chamber by means of a positive material and air transport system. Furthermore, these mills offer great turbulence and high air volume ensures a minimum temperature increase facilitating the handling of heat-sensitive materials.

The Air Classifying Mill market is characterized by the presence of a large number of small and medium-sized enterprises. The leading players in the market are focused on expanding their product portfolios to cater to the needs of a wide range of customers. The key strategies adopted by the leading players in the Air Classifying Mill market include product innovation, mergers & acquisitions, and expansion into new geographies. The air classifying mill market is highly competitive with a large number of players.

Key players in the market include:

These companies hold a significant share of the market owing to their strong brand presence and product offerings.

| Attribute | Details |

|---|---|

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | million for Value and Units for Volume |

| Key Regions Covered | North America; Europe; Asia Pacific; Latin America; Middle East and Africa (MEA); RoW |

| Key Countries Covered | USA, Canada, Mexico, Germany, United Kingdom, France, Russia, Brazil, Argentina, Japan, Australia, China, India, Indonesia, South Korea |

| Key Segments Covered | Type, Application, Sales Channel, Region |

| Key Companies Profiled | Hosokawa Alpine; British Rema; Hosokawa Micron; NETZSCH; CMS; RIECO; Ultra Febtech; Kaps Engineers; NSI EQUIPMENT (P)LTD; Kemutec; BulkInside; Yinda Machinery; Clarion Engineers & Tech LLP; Innovative Fab |

| Report Coverage | Strategic Growth Initiatives, DROT Analysis, Market Forecast, Company Share Analysis, Market Dynamics and Challenges, and Competitive Landscape. |

| Customization & Pricing | Available upon Request |

The global air classifying mill market is estimated to be valued at USD 1,096.8 million in 2025.

It is projected to reach USD 1,838.3 million by 2035.

The market is expected to grow at a 5.3% CAGR between 2025 and 2035.

The key product types are horizontal mills, vertical mills and circular mills.

food processing segment is expected to dominate with a 42.0% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Airless Paint Spray System Market Size and Share Forecast Outlook 2025 to 2035

Air Caster Skids System Market Size and Share Forecast Outlook 2025 to 2035

Airborne Molecular Contamination Control Services Market Forecast and Outlook 2025 to 2035

Airflow Balancer Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Cabin Environment Sensor Market Forecast and Outlook 2025 to 2035

Aircraft Flight Control System Market Size and Share Forecast Outlook 2025 to 2035

Airborne Radar Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Electric Motor Market Forecast Outlook 2025 to 2035

Airport Ground Transportation Market Forecast and Outlook 2025 to 2035

Airless Sprayer Accessories Market Size and Share Forecast Outlook 2025 to 2035

Air Purge Valve Market Size and Share Forecast Outlook 2025 to 2035

Air Flow Sensors Market Size and Share Forecast Outlook 2025 to 2035

Air Separation Plant Market Size and Share Forecast Outlook 2025 to 2035

Air Cooled Turbo Generators Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Cooling Turbines Market Size and Share Forecast Outlook 2025 to 2035

Air Conditioning Compressor Market Size and Share Forecast Outlook 2025 to 2035

Air Measuring Equipment Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Smoke Detection and Fire Extinguishing System Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Hose Fittings Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Cabin Interior Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA