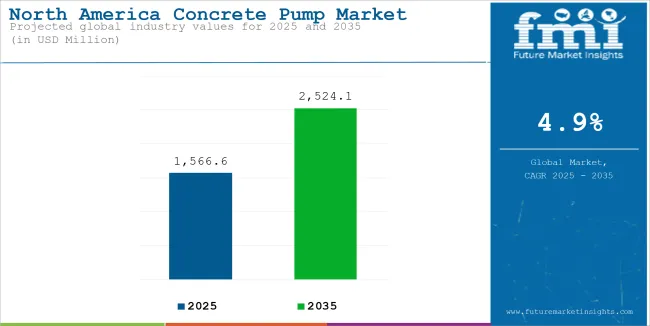

The North America Concrete Pump Market was valued at USD 1236.7 Million in 2020 and reached a valuation of USD 1566.6 Million by 2025. The market is anticipated to register a Y-o-Y growth of 4.0% in the year 2025.Over the assessment period (2025 to 2035), the market is projected to expand at a value CAGR of 4.9% and reach USD 2524.1 Million by the end of the forecast period.

Concrete pumps are efficient machineries meant to get liquid concrete to building sites quickly and accurately. Concrete pumps play an important role in the modern construction industry, providing answers to complex development, such as skyscrapers, infrastructure, and residential construction; they reduce manual labour on site, increase productivity, and maintain quality.

Concrete pumps vary in type according to the construction industry's demands. Boom pumps are suitable for large projects as the hydraulic arm of the pump enables placing concrete at a great height or over obstacles, thus more suitable for high structures and bridges. Trailer pumps are more suitable for medium-scale construction because they are compact in design and highly valued for the flexibility they offer with cost-effectiveness.

Line pumps are also more versatile and are increasingly used for small projects like sidewalks, driveways, and pool construction. North America is increasingly urbanizing, and the development of infrastructure creates a demand for concrete pumps.

Further advancement in technology will lead to more pervasive use of concrete pumps equipped with smart features like automated controls and advanced safety mechanisms. There is growing interest in high-performance equipment capable of performing across different terrains and harsher environments, positioning concrete pumps as integral equipment in modern North American construction projects.

| Attribute | Value |

|---|---|

| Estimated Size (2025E) | USD 1,566.6 million |

| Projected Value (2035F) | USD 2,524.1 million |

| CAGR 2025 to 2035 | 4.9% |

The market is expected to grow approximately 1.6 times during this period Between 2025 and 2035, the traction motor markets is expected to grow significantly, reaching a valuation of approximately USD 2524.1 million by 2035, with a projected CAGR of 4.9%.

This growth will be driven by increasing urbanization and industrialization in North America, where renewable solution adapting is expanding rapidly. Technology advancement and increasing infrastructure development will continue to play a pivotal role, with the development of next-generation trencher attachment market that offer enhanced performance, and cheaper costs.

Increasing Infrastructure Development Fuels Demand for Efficient Concrete Pump Solutions

Infrastructure development across North America is a key driver of the concrete pump market. Governments are committing vast sums to upgrade old infrastructure, construct new transportation networks, and increase urban housing. For instance, the Bipartisan Infrastructure Law in the USA commits USD 1.2 trillion toward roads, bridges, and utilities development, thus emphasizing the need for efficient construction equipment.

Concrete pumps become an essential commodity for such large-scale undertakings where concrete can easily be delivered and placed at high inaccessible locations accurately and in haste. Unlike others, these machines reduce labour dependency, minimize losses of materials to waste, and improve the general timeline of most projects.

What's more is that their incorporation into high rise buildings and massive structures like dams and bridges delivers uniformity of construction. There is an expectation that, with ongoing urbanization and industrialization in the region, concrete pump usage will gradually continue to increase. Their suitability for meeting modern construction needs, along with their efficiency, will class them as critical machinery equipment in large-scale infrastructure development.

Rising Adoption of High-Pressure Pumps for Specialized Applications

Increasing sophistication in construction makes North America require more high-pressure concrete pumps. Such highly specialized pumps are made to handle extreme conditions- pumping concrete to towering heights or over long distances, making them great for specialized applications.

For example, high-pressure pumps are essential in the construction of skyscrapers, tunnels, hydroelectric dams, and other giant projects in which traditional equipment cannot achieve the required performance. They ensure smooth operations by maintaining consistent flow rates and avoid blockages, even in dense or highly viscous concrete mixtures. Contractors are increasingly using these pumps to promote high productivity and structural integrity on tough sites.

The efficiency of high-pressure pumps when working on demanding projects reduces the construction time while efficiently expanding the bottom line. As the scope and complexity of construction projects increase, the adoption of these high-performance machines is expected to rise and place them as a cornerstone of modern construction technologies.

Trend: Integration of IoT and Automation in Concrete Pumps

The North American construction industry is undergoing a paradigm shift with IoT technology and automation in concrete pumps. These innovations are revolutionizing the conventional operations with the prowess of advanced monitoring and control. IoT-enabled concrete pumps keep in record in real-time the performance of the pumps, concrete flow rates, and equipment health conditions, thus facilitating proactive action by the contractor to not let these situations worsen.

It is not just efficiency but also maintenance downtime reduction and maintaining the life expectancy of the equipment. On its part, automation features like remote operation, smart pumping systems, and self-diagnostics make the process less cumbersome for the contractors, as they let them prioritize critical tasks. These technologies enhance safety through reduced human intervention in hazardous areas and high accuracy in concrete placement.

For instance, smart pumps automatically regulate flow rates and pressure to fit project specifications to ensure uniform delivery and reduce material wastage. As contractors seek innovative solutions to optimize resources and improve project outcomes, the adoption of IoT and automation in concrete pumps is set to grow, redefining the industry’s operational standards.

High Initial Costs of Advanced Concrete Pumps Pose Challenges

Despite their numerous advantages, advanced concrete pumps face significant barriers to adoption due to their high initial costs. These machines, especially high-pressure pumps and IoT-enabled ones, come with a heavy price tag. It is mainly due to the expensive materials used in their manufacture, the most sophisticated hydraulic systems, and high-end monitoring technologies.

Small-scale contractors and construction companies cannot afford to spend that amount of money because they are working on very low budgets, hence restricting access to the efficiency and precision provided by advanced pumps. Moreover, training operating personnel on newer systems would again add cost that would put pressures on the wallet.

In companies working on a smaller project level, it will be more troublesome to determine an appropriate cost benefit ratio that calls for the investments. In fact, to avoid these difficulties manufacturers are striving toward developing affordable but not cost-compromised variants that preserve prime features at competitive prices.

Other initiatives include subsidies or low-interest financing programs offered by the government. Innovation should always be weighed against the cost. With proper balancing, it will ensure greater access to high-performance concrete pumps even among the most budget-conscious firms.

From 2020 to 2024, the North America Concrete Pump market witnessed steady growth, driven by rising demand renewable solutions, advancements in technology, and increasing adoption across various industries. The market expanded from approximately USD 1236.7 Million in 2020 to USD 1491.3 Million in 2024, growing at a CAGR of 4.0%. Adoption during seasonal change compelled industries to adopt Engine Starter fluids.

Between 2025 and 2035, the traction motor market is expected to grow significantly, reaching a valuation of approximately USD 2524.1 million by 2035, with a projected CAGR of 4.9%. This growth will be propelled by increasing urbanization and industrialization, in markets of North America where technology is expanding rapidly. Rise of adoption is energy saving systems will continue to play a pivotal role, with the development of next-generation solutions that offer enhanced performance and reduced costs.

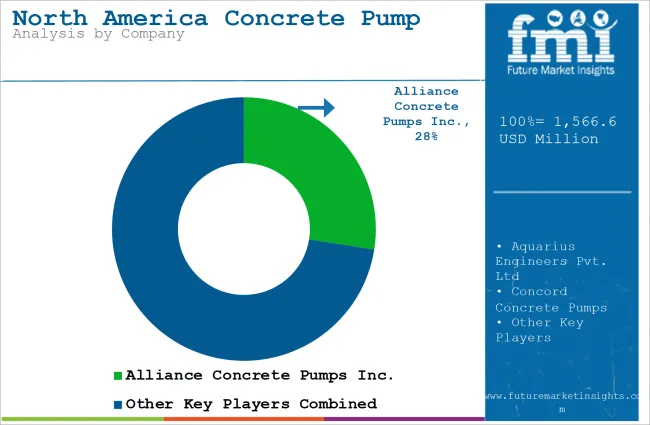

The North America Concrete Pump market is moderately fragmented, with a mix of established multinational corporations and regional players competing for market share. Larger companies dominate the market with their extensive product portfolios, advanced manufacturing capabilities, and strong global distribution networks. However, regional and niche players contribute significantly by catering to local markets with cost-effective solutions.

Tier 1 companies include industry leaders with annual revenues exceeding USD 70 Million. These companies are currently capturing a significant share of 20% to 25%. These frontrunners are characterized by high production capacity and a wide product portfolio.

They are distinguished by extensive expertise in manufacturing and a broad geographical reach, underpinned by a robust consumer base. The firms provide a wide range of products and utilize the latest technology to meet regulatory standards. Prominent companies within this tier I players include Liebherr, KLEIN GmbH, Aquarius Engineers Pvt. Ltd.

Tier 2 companies encompass most of the small-scale enterprises operating within the regional sphere and catering to specialized needs with revenues between USD 40-70 Million. These businesses are notably focused on meeting local demand and are hence categorized within the Tier 2 segment.

They are small-scale participants with limited geographical presence. In this context, Tier 2 is acknowledged as an informal sector, indicating a segment distinguished by a lack of extensive organization and formal structure in comparison to the structured one. Tier II Players such as Concord concrete pumps, Alliance Concrete Pumps Inc. and others have been considered in this tier where they are projected to account for 45-50% of the overall market.

Tier 3 includes the majority of small-scale companies operating at the local presence and serving niche having revenue below USD 40 Million. These companies are notably oriented towards fulfilling local demands and are consequently classified within the tier 3 share segment.

They are small-scale players and have limited geographical reach. The manufacturers such as Tier III Players Sany, Schwing America Inc. XCMG, Zoomlion and others are expected to hold 30-35% of the share.

| Countries | CAGR 2025 to 2035 |

|---|---|

| USA | 5.0% |

| Canada | 4.5% |

| Mexico | 4.1% |

Infrastructure and agricultural projects are going very strong in the United States, and their demand for concrete pumps is high. The Bipartisan Infrastructure Law has directed tremendous investment towards updating transportation networks, bridges, and utility infrastructure across the country. Because of the gigantic size of such projects, contractors now require concrete pumps to ensure accurate and efficient concrete placement, ensuring that deadlines are met and quality levels are maintained.

High-rise buildings, highways, and renewable energy facilities are some of the main areas that cannot do without concrete pumps. Urban construction works, especially in large cities, will also require more advanced pumps in order to convey concrete into tightly confined spaces without causing much commotion.

Concrete pumps are in high demand in states like California and Texas as the systems of water management and irrigation expand. Modern agricultural practices involve sustainability and resource optimization, hence the ability to construct reservoirs, water channels, and irrigation infrastructure will require concrete pumps.

Advances in feature-rich pumps-high-pressure and IoT-based monitoring systems are currently gaining momentum for improving operational efficiencies while saving labour costs. Driven by government support through subsidies and financing schemes, these advancements drive the USA concrete pump market forward in the country as a leading force towards the construction and agricultural developments across the nation.

Canada is investing in infrastructure development and hence sustainable growth, which causes increased demand for concrete pumps from many fronts. Such key major infrastructure programs shall include upgrading transportation systems and utility networks and supporting green energy projects.

These initiatives prioritize the use of modern construction equipment, such as concrete pumps, for their efficiency and precision in delivering high-quality results. Concrete pumps are especially critical in Canada’s urban centres, where high-rise construction and complex infrastructure projects require advanced solutions for effective concrete placement.

The country's efforts in renewable energy, especially wind and hydroelectric projects, are also compelling the demand for concrete pumps. Such projects generally involve difficult terrain and require the pumping of concrete over long distances and to a considerable height.

Canada's agricultural sector also contributes to the increasing demand for concrete pumps, especially in the construction of water management systems and storage facilities in areas such as Alberta and Saskatchewan. Farmers are using these machines to increase productivity and resource efficiency, with government programs that encourage sustainable farming practices. These trends indicate the growing concrete pumps in Canada's construction and agricultural sectors, hence underlining their significance to the country in its development activities.

The concrete pump market in Mexico is rapidly growing, developing with urban growth and industrial development. Several government programs for the National Infrastructure Plan focus on improving transport, energy networks, and housing developments in the country.

The volumes of work under these projects must be executed accurately and efficiently using highly advanced construction machineries, especially concrete pumps, to handle huge volumes. Such factors like building high-rise skyscrapers and metro systems besides commercial complexes favour boom pump acceptance in urban developments.

A huge potential driver for the concrete pump market in Mexico would be the development of manufacturing hubs and industrial parks that will have to be supported by strong, efficient construction. The government has been pushing renewable energy projects, especially wind and solar farms, so there is growing demand for concrete pumps in terms of constructing all the infrastructure supporting these, like turbine foundations and utility installations.

In another sector, the agriculture sector of Mexico is the region where concrete pumps are gaining traction. The irrigation projects and the construction of water storage systems in areas prone to drought are crucial and require a very high precision with speed that only concrete pumps can provide in their construction.

With the continuous modernization of its infrastructures and industrial base in Mexico, this will continue to rise in demand for high-tech concrete pumps and by that aspect that is very essential towards the development agenda of the country.

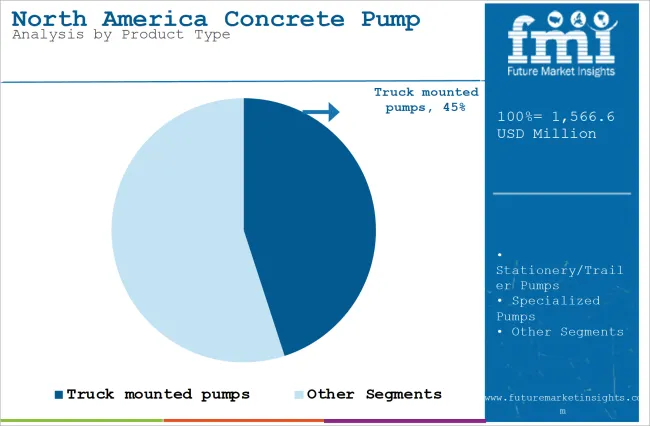

| By Product Type | Market Share 2024 |

|---|---|

| Truck mounted pumps | 45% |

Truck-mounted pumps have dominated among the product types of the North America concrete pump market because no other product has rivalled the flexibility and operational efficiency. Truck-mounted pumps bring mobility and functionality, making them an ideal choice for any construction work from a residential building to large-scale infrastructure development.

The capability to hold and operate directly from a truck chassis does not require any further equipment, leading to significant reductions in setup times while increasing productivity on site.

Truck-mounted pumps are particularly preferred for urban construction works where space availability is limited, and the need is to supply concrete in congested areas. Hydraulic boom arms give excellent reach and flexibility, and with this reach, concrete can be placed at inaccessible locations such as upper floors or behind obstacles.

They are therefore indispensable for high-rise buildings, bridges, and other complex structures Another factor making them so popular is the desire for quicker timelines in construction activities. Truck-mounted pumps with high speed and operational convenience meet this end.

Also, their capability to process a range of consistencies also makes it capable of application from small residential undertakings to gigantic infrastructure works. This flexibility, coupled with efficiency and reliability, positions truck-mounted pumps as the most important product type in the North America concrete pump market.

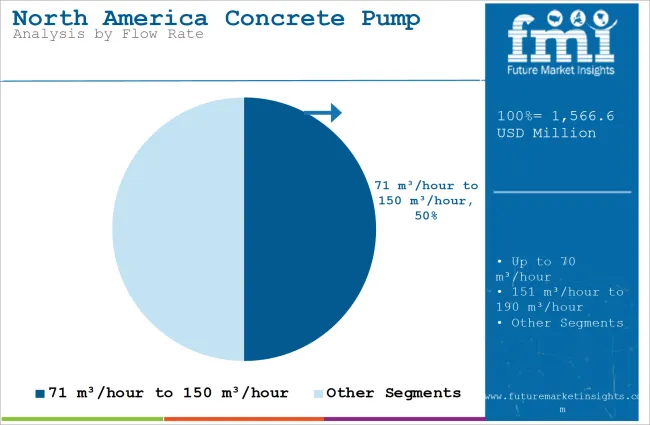

| By Flow Rate | Market Share 2024 |

|---|---|

| 71 m³/hour to 150 m³/hour | 50% |

The 71 m³/hour to 150 m³/hour flow rate segment is notable as the largest category in the North America concrete pump market, because it caters to a wide range of construction works. This flow rate range covers an ideal balance of performance and efficiency for medium to large-scale projects.

Most people find this flow range suitable for the construction of residential complexes, commercial buildings, and infrastructure development. Its capacity is suitable for most construction conditions where neither very low nor exceptionally high flow rates are necessary.

This is because it has been able to meet the increased demand for the fast completion of projects with high accuracy in the placement of concrete. Pumps in this category are capable of producing enough output for most applications, such as the pouring of foundations, floors, and columns, making them essentials for contractors who undertake different types of projects.

Further, they have enough flexibility for varied concrete strengths regardless of general-purpose or even highly specialized such as in heavy industrial buildings. This flow rate range is also cost-effective. High flow rates of more than 190 m³/hour are applicable to massive infrastructure projects, such as dams and highways. However, for common construction jobs, such flow rates are too expensive and too much.

The section provides comprehensive assessments and insights that highlight current opportunities and emerging trends for companies in developed and developing countries. It analyses advancements in manufacturing and identifies the latest trends poised to drive new applications in the.

A few key players in the North America Concrete Pump market are actively enhancing capabilities and resources to cater to the growing demand for the compound across diverse applications. Leading companies also leverage partnership and joint venture strategies to co-develop innovative products and bolster resource base.

Significant players are further introducing new products to address the increasing need for cutting-edge solutions in various end-use sectors. Geographic expansion is another important strategy that is being embraced by reputed companies. Start-ups are likely to emerge in the sector through 2035, thereby making it more competitive.

Key companies are investing in continuous research for producing new products and increasing their production capacity to meet end-user demand. They are also showing an inclination toward adopting strategies, including acquisitions, partnerships, mergers, and facility expansions to strengthen their footprint.

Industrial Developments

According to the product type the North American Concrete Pumps market is categorized into Truck Mounted Pumps, Stationery/ Trailer Pumps, Specialized Pumps

According to the flow rate, the North America Concrete Pump market is categorized into Up to 70 m³/hour, 71 m³/hour to 150 m³/hour, 151 m³/hour to 190 m³/hour, Above 190 m³/hour

According to the application the North America Concrete Pump market is categorized into Fuel and electric.

According to the scale of operations the north America Pump market is categorized into Small Scale Operation, Medium Scale Operation, Large Scale Operation

On the basis of region, the traction motors market is categorized into North America.

The overall market size for North America Concrete Pump market was USD 1491.3 million in 2024.

The North America Concrete market is expected to reach USD 2524.1 million in 2035.

Increase in infrastructure development and technological advancement will drive the North America concrete Pump market during the forecast period.

The top 3 countries which drives the development of North America Concrete Pump Market are USA, Canada and Mexico.

Truck-mounted pumps are expected to command significant share over the assessment period.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Northern Blotting Market Size and Share Forecast Outlook 2025 to 2035

Northern Europe Calcium Sulphate Market Size and Share Forecast Outlook 2025 to 2035

North America Boat Trailer Market Size and Share Forecast Outlook 2025 to 2035

North America Cryogenic Label Printer Market Size and Share Forecast Outlook 2025 to 2035

North America Chitosan Market Size and Share Forecast Outlook 2025 to 2035

North America Underground Mining Vehicle Market Size and Share Forecast Outlook 2025 to 2035

North America Bulk Aseptic Packaging Market Size and Share Forecast Outlook 2025 to 2035

North America Licorice Extract Market Size and Share Forecast Outlook 2025 to 2035

North America Par Baked Bread Market Size and Share Forecast Outlook 2025 to 2035

North America Silo Bags Market Size and Share Forecast Outlook 2025 to 2035

North America Fresh Meat Packaging Market Size and Share Forecast Outlook 2025 to 2035

North America Ceramic Barbeque Grill Market Size and Share Forecast Outlook 2025 to 2035

North America Temperature Sensor Market Size and Share Forecast Outlook 2025 to 2035

North American Dietary Supplements Market Size and Share Forecast Outlook 2025 to 2035

North America Head-up Display Market Size and Share Forecast Outlook 2025 to 2035

North America, Europe & Asia Pacific Legal Cannabis Market Size and Share Forecast Outlook 2025 to 2035

North America Ceiling Cassette Market Size and Share Forecast Outlook 2025 to 2035

North America Pressure Regulating Valves Market Size and Share Forecast Outlook 2025 to 2035

North America Flame Retardant Thermoplastics Market Size and Share Forecast Outlook 2025 to 2035

Fire Pit Market Analysis in North America - Growth, Trends and Forecast from 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA