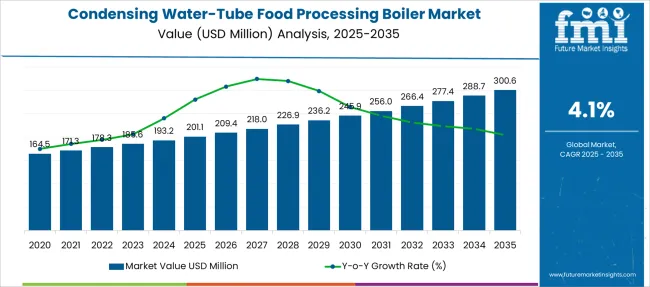

The Condensing Water-Tube Food Processing Boiler Market is estimated to be valued at USD 201.1 million in 2025 and is projected to reach USD 300.6 million by 2035, registering a compound annual growth rate (CAGR) of 4.1% over the forecast period.

| Metric | Value |

|---|---|

| Condensing Water-Tube Food Processing Boiler Market Estimated Value in (2025 E) | USD 201.1 million |

| Condensing Water-Tube Food Processing Boiler Market Forecast Value in (2035 F) | USD 300.6 million |

| Forecast CAGR (2025 to 2035) | 4.1% |

The condensing water tube food processing boiler market is undergoing steady growth as food manufacturers seek energy-efficient, environmentally responsible, and cost-effective steam generation solutions. Rising operational costs and stringent emission standards are driving the adoption of advanced condensing technologies that optimize fuel utilization and minimize carbon footprint.

The market is benefiting from increasing investments in modernizing food processing plants, where reliable and efficient steam systems are critical for maintaining productivity and product quality. Technological advancements in heat recovery, controls, and materials are further enhancing boiler performance and lifecycle value.

Future expansion is expected to be supported by the growing focus on decarbonization, adoption of cleaner fuels, and integration of smart monitoring systems, paving the way for broader deployment in both new facilities and retrofit projects across diverse food processing segments.

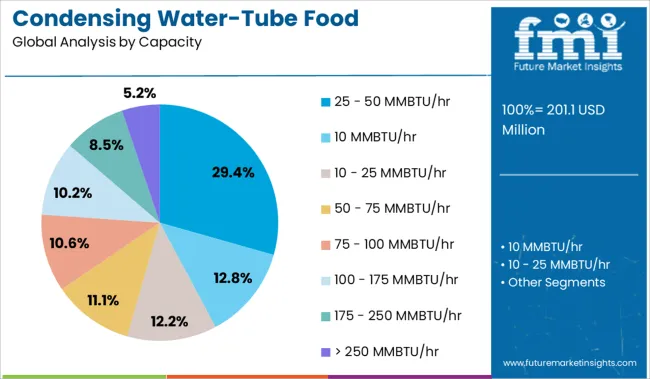

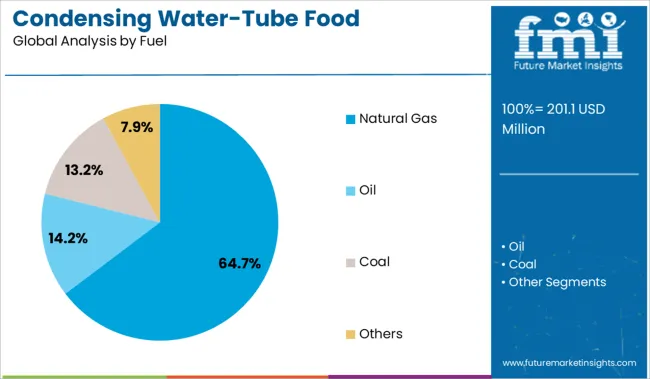

The condensing water-tube food processing boiler market is segmented by capacity, fuel, and geographic regions. The capacity of the condensing water-tube food processing boiler market is divided into 25 - 50 MMBTU/hr, 10 MMBTU/hr, 10 - 25 MMBTU/hr, 50 - 75 MMBTU/hr, 75 - 100 MMBTU/hr, 100 - 175 MMBTU/hr, 175 - 250 MMBTU/hr, and > 250 MMBTU/hr. In terms of fuel, the condensing water-tube food processing boiler market is classified into Natural Gas, Oil, Coal, and Others. Regionally, the condensing water-tube food processing boiler industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by capacity, the 25 to 50 MMBTU/hr range is expected to account for 29.4% of the total market revenue in 2025, making it the leading capacity segment. This prominence is attributed to its suitability for mid to large scale food processing operations where consistent and high volume steam demand is present.

The capacity range has been favored for its balance between operational efficiency and scalability, enabling food processors to meet production needs without incurring excessive capital or operational costs. Facilities operating within this range have benefited from the ability to optimize floor space, minimize downtime through modular configurations, and maintain compliance with regulatory standards.

The adaptability of this capacity to different process loads and plant layouts has reinforced its dominance in environments where performance, flexibility, and cost effectiveness are critical.

Segmented by fuel type, natural gas is projected to hold 64.7% of the market revenue in 2025, establishing itself as the dominant fuel segment. This leadership is driven by its widespread availability, competitive pricing, and favorable environmental profile compared to alternative fossil fuels.

Food processors have increasingly chosen natural gas fueled boilers to reduce greenhouse gas emissions, comply with tightening air quality regulations, and achieve lower operating costs through higher combustion efficiency. The ease of integration with existing infrastructure and the ability to deliver precise and reliable heat output have further strengthened its adoption.

The transition away from oil and coal toward cleaner fuels has positioned natural gas as the preferred energy source, reflecting both economic and sustainability imperatives shaping procurement decisions in the food processing industry.

Rising food industry demand, energy cost pressures, and environmental regulations are accelerating adoption of condensing water‑tube boilers. Future growth will stem from modular designs, waste heat recovery integration, and decentralized plant deployment.

Food processing facilities such as confectionery plants, dairies, breweries, and ready‑meal manufacturers are prioritizing boilers that deliver high steam output with minimal energy loss. Condensing water‑tube boilers recover latent heat from flue gases, achieving efficiencies over 95 percent and lowering fuel costs significantly. Strict emissions standards and carbon reporting mandates push operators toward low‑NOx and low‑CO₂ equipment. These boilers also provide rapid steam delivery and flexible load matching, which suits batch cooking cycles and cleaning regimes common in food plants. Their compact footprint and quicker warm‑up time reduce operational disruption. As cost of natural gas and LPG increases, plant managers adopt condensing water‑tube systems for precise control, compliance assurance, and measurable savings on energy and emissions.

Opportunities emerge through bundling condensing water‑tube boilers with waste‑heat recovery units, phase‑change thermal storage, and on‑site renewable generation like biomass or solar thermal. Modular boiler packages that can be rapidly installed, scaled, or relocated are attractive for seasonal production or contract food manufacturing units. Small and medium‑scale processors can adopt compact plug‑and‑play systems, avoiding high capital outlays. Strategic alliances with design‑build engineering firms and equipment leasing companies offer operators flexible financing and lifecycle service plans. Expanding into regions with growing packaged food demand, such as Asia‑Pacific and Latin America, allows suppliers to tailor systems for variable feedstock and fuel types. Training and certification programs for maintenance staff further boost long‑term reliability and customer trust.

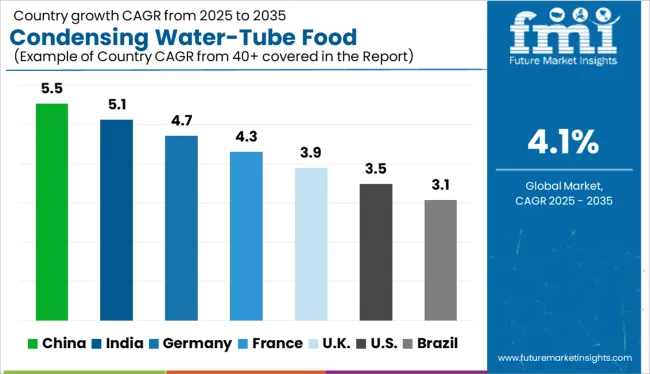

| Country | CAGR |

|---|---|

| China | 5.5% |

| India | 5.1% |

| Germany | 4.7% |

| France | 4.3% |

| Uk | 3.9% |

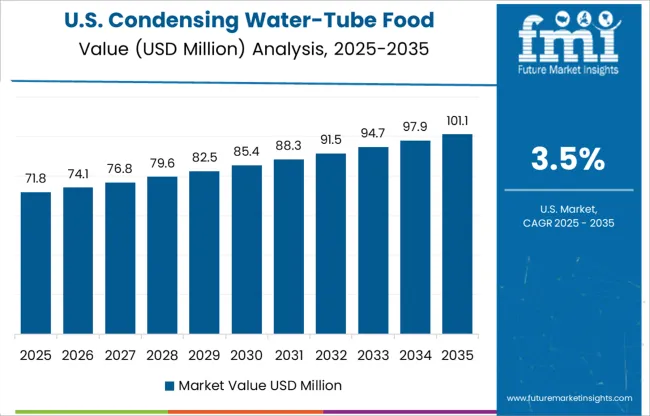

| USA | 3.5% |

| Brazil | 3.1% |

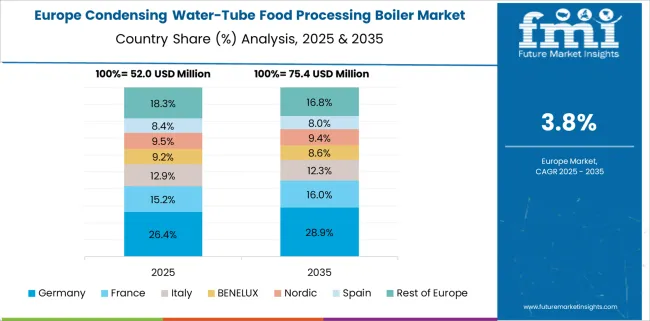

The global condensing water-tube food processing boiler market is projected to grow at a CAGR of 4.1% from 2025 to 2035, driven by increasing demand for energy-efficient thermal systems, stringent emission regulations, and sustainability goals in the food processing sector. Among BRICS nations, China leads with a 5.5% CAGR, supported by modernization of food manufacturing, urban industrial upgrades, and energy transition policies. India follows at 5.1%, where rising packaged food production and cost-efficient plant retrofits are accelerating adoption. Germany, a key OECD player, shows a 4.7% CAGR due to green building standards and eco-label compliant boilers. In contrast, the United Kingdom (3.9%) and United States (3.5%) demonstrate slower growth due to market maturity, legacy infrastructure, and moderate replacement cycles. This report covers detailed analysis of 40+ countries, and the top five countries have been shared as a reference.

Strong industrial expansion and tightening energy efficiency norms are driving the condensing water-tube food processing boiler market in China, which is advancing at a 5.5% CAGR. Modernization of food manufacturing clusters, particularly in dairy and beverages, is accelerating adoption of energy-efficient boilers. Regional governments are incentivizing low-emission technologies through carbon credit mechanisms, and dual-fuel configurations are becoming common across processing plants. Automation in boiler operation is further optimizing heat recovery, reducing gas consumption per production cycle. Both domestic OEMs and foreign players are investing in smart boiler upgrades to meet zero-waste mandates.

The condensing water-tube boiler market in India is projected to grow at a 5.1% CAGR, driven by expanding packaged food manufacturing and pressure to minimize thermal waste. Increased consumption of ready-to-eat meals and functional foods is prompting infrastructure upgrades across mid-sized processing plants. Demand is also being influenced by national energy efficiency schemes such as PAT (Perform Achieve Trade), which encourage industrial units to lower specific fuel consumption. Heat exchange optimization is gaining traction, especially in plants using multiple batch cycles. Cost-sensitive buyers are opting for modular condensing systems compatible with both LPG and biomass fuel.

Germany is experiencing steady growth in its condensing water-tube food processing boiler market, expected to expand at a 4.7% CAGR through 2035. Industrial energy policy reforms emphasizing sustainability are prompting food companies to transition to high-efficiency thermal systems. The market is increasingly defined by demand for low-NOx condensing boilers that can integrate with renewable gas infrastructure. Precision thermal control, enabled by sensor-based automation, is also becoming standard for heat-intensive applications like baking and brewing. The preference is shifting toward stainless steel heat exchangers that reduce fouling and extend boiler lifespans.

The United Kingdom is projected to witness moderate growth in this segment, with a 3.9% CAGR from 2025 to 2035. Aging food manufacturing infrastructure across the UK is gradually being upgraded with low-emission condensing boiler systems. Strict DEFRA regulations are compelling processors to integrate heat recovery and smart gas usage controls. Smaller producers are increasingly leveraging leasing options and energy-as-a-service models to avoid large capital investments. There is notable interest in hybrid boiler setups that pair with electric backup systems for better uptime. Demand is most pronounced in meat processing and frozen foods, where high thermal loads are routine.

The United States condensing water-tube food processing boiler market is advancing at a 3.5% CAGR, supported by cost-efficiency goals and sustainability pressures within the food industry. While overall boiler replacement rates remain slow, federal incentives and local decarbonization mandates are pushing investment in condensing models with reduced fuel use per output unit. Integration with industrial control systems is enabling better monitoring of flue gas composition and heat losses. Demand is led by high-volume facilities in dairy, baked goods, and beverage sectors. Natural gas remains the dominant fuel, though compatibility with renewable gas is gaining importance in new projects.

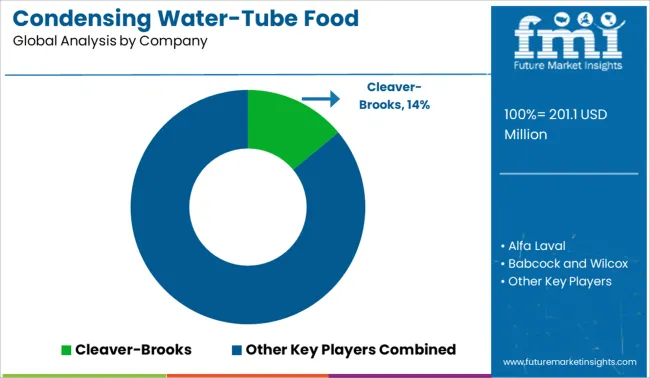

The condensing water-tube food processing boiler market is moderately fragmented, with several global and regional manufacturers competing on thermal efficiency, clean steam delivery, and compliance with food-grade standards. Cleaver-Brooks leads the market with a significant share, driven by its advanced energy recovery systems, modular boiler platforms, and robust service network across the food processing sector. Key Tier 1 players like Alfa Laval, Fulton, and Miura America offer compact, low-emission designs with high operational uptime. Tier 2 firms such as Thermax, Hurst Boiler, and Clayton Industries serve regional or specialized applications with customizable systems. The market's growth is propelled by increasing demand for sustainable processing, automation integration, and strict hygiene regulations across food and beverage facilities.

| Item | Value |

|---|---|

| Quantitative Units | USD 201.1 Million |

| Capacity | 25 - 50 MMBTU/hr, 10 MMBTU/hr, 10 - 25 MMBTU/hr, 50 - 75 MMBTU/hr, 75 - 100 MMBTU/hr, 100 - 175 MMBTU/hr, 175 - 250 MMBTU/hr, and > 250 MMBTU/hr |

| Fuel | Natural Gas, Oil, Coal, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Cleaver-Brooks, Alfa Laval, Babcock and Wilcox, Babcock Wanson, Clayton Industries, Forbes Marshall, Fulton, Hurst Boiler, Johnston Boiler, Miura America, Par Techno-Heat, Rentech Boilers, Thermax, Thermodyne Boilers, and Viessmann |

| Additional Attributes | Dollar sales by boiler capacity, fuel type, and food processing application; regional demand influenced by energy efficiency regulations, food safety standards, and industrial modernization; innovation in heat recovery, modular design, and smart controls; cost dynamics driven by installation, maintenance, and fuel supply; environmental impact related to emissions and water usage; and emerging use cases in clean-label production, ready-to-eat meals, and dairy processing. |

The global condensing water-tube food processing boiler market is estimated to be valued at USD 201.1 million in 2025.

The market size for the condensing water-tube food processing boiler market is projected to reach USD 300.6 million by 2035.

The condensing water-tube food processing boiler market is expected to grow at a 4.1% CAGR between 2025 and 2035.

The key product types in condensing water-tube food processing boiler market are 25 - 50 mmbtu/hr, 10 mmbtu/hr, 10 - 25 mmbtu/hr, 50 - 75 mmbtu/hr, 75 - 100 mmbtu/hr, 100 - 175 mmbtu/hr, 175 - 250 mmbtu/hr and > 250 mmbtu/hr.

In terms of fuel, natural gas segment to command 64.7% share in the condensing water-tube food processing boiler market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Condensing Unit Market Trends-Growth, Demand & Forecast 2025 to 2035

Condensing Chemical Boiler Market Size and Share Forecast Outlook 2025 to 2035

Condensing Low Temperature Commercial Boiler Market Size and Share Forecast Outlook 2025 to 2035

Condensing Food Processing Boiler Market Size and Share Forecast Outlook 2025 to 2035

Non-Condensing Fire Tube Chemical Boiler Market Size and Share Forecast Outlook 2025 to 2035

Non-Condensing Water Tube Chemical Boiler Market Size and Share Forecast Outlook 2025 to 2035

Non-Condensing Fire Tube Food Processing Boiler Market Size and Share Forecast Outlook 2025 to 2035

Gas Fired Condensing Low Temperature Commercial Boiler Market Size and Share Forecast Outlook 2025 to 2035

Industrial Condensing Units Market Size and Share Forecast Outlook 2025 to 2035

Evaporative Condensing Units Market Trend Analysis Based on Type, Operation, Application, and Region 2025 to 2035

Transportation Condensing Units Market Growth – Trends & Forecast 2025 to 2035

Gas Fired Water-Tube Food Processing Boiler Market Size and Share Forecast Outlook 2025 to 2035

Boiler Control Market Size and Share Forecast Outlook 2025 to 2035

Boiler Water Treatment Chemicals Market Size and Share Forecast Outlook 2025 to 2035

Boiler Market Size and Share Forecast Outlook 2025 to 2035

Boiler Safety System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Egg Boiler Market Size and Share Forecast Outlook 2025 to 2035

Steam Boiler Market Size and Share Forecast Outlook 2025 to 2035

Combi Boiler Market Growth – Trends & Forecast 2025 to 2035

Office Boiler Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA