The draw heat setting winder market is expected to expand significantly between 2025 and 2035, attributed to increased textile industry demand for efficient processes in yarn winding, heat setting, and tension control. The adoption of draw heat setting winders in the textile industry has witnessed a significant upturn as textile manufacturers strive to produce superior quality yarns, increase operational efficiency, and facilitate seamless operations in textile production.

Such machines are commonly used in the continuous production of synthetic and natural fibres polymerized polyester, nylon, cotton and acrylic where yarn dimensions are stabilized with heat to minimize shrinkage in the subsequent processing of textiles. Increasing demand for high-quality textile products for apparel, home furnishing, and industrial textile applications are further propelling the market growth.

Moreover, the increasing adoption of high-performance fibres in applications such as technical textiles, sportswear, and industrial fabrics has also driven the demand for draw heat setting winders that offer advanced tension control and precision winding capabilities.

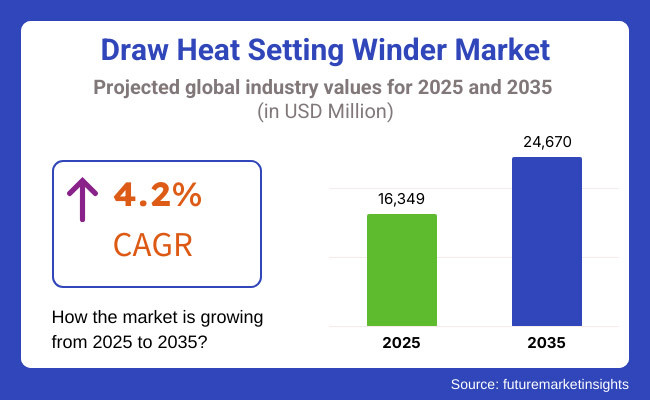

The market is projected to grow at a CAGR of 4.2% from 2025 to 2035 due to developments in textile machinery, increased production of synthetic fibres, and energy-efficient, high-speed winding operations. Furthermore, the growing trend of industrialized textile production in developing economies, along with increasing automation in textile production, is also accelerating the market growth for draw heat setting winders.

Additionally, textile producers are placing greater emphasis on energy-efficient, high-output winding machines, in order to lower the cost of operation and increase output capacity.

The growing trend of customized textiles and innovative fabric designs in the fashion and apparel industry is also having a positive impact trend of the market demand, due to uniform treatment of yarn during the heat setting process provided by the draw heat setting winders, which ensures product consistency and quality among the textiles utilized in various applications.

Primarily used for stabilizing the yarn structure, eliminating internally stored tension, and enhancing the quality of textile yarns in later processing, draw heat setting winders constitute an essential segment of this process. The core fabric types used in these machines are polyester, nylon, acrylic, and blended fibres. Draw Heat Setting Winders for Polyester: Polyester is the most widely processed material across draw heat setting winders, owing to its significant application in apparel, home textiles, and industrial textiles.

Nylon is a widely used material in technical textiles and industrial applications because of its higher strength, flexibility, and resistance to wear and tear. Other areas such as Home furnishing and Knitwear have also started adopting acrylic fibres which in-turn increases demand for these blow moulded, soft winders, and heat setting winders etc. in high-production fill rate areas.

Rising demand for operational cost reduction among textile manufacturers is pushing them towards more energy efficient and high-speed drawing heat setting winders which reduce operational cost and enable high quality products with higher productivity. Additionally, automation and improvements in technology such as automatic doffing, programmable control systems, and tension controls in real-time have augmented their proliferation in bigger textile factories.

North America is anticipated to dominate the draw heat setting winder market, owing to the presence of several textile manufacturing units, high demand for advanced textile machinery, and increasing focus on automation in production. The USA and Canada are important markets, where producers are continually investing in high-speed winding and heat-setting machines to deliver yarn quality and operational efficiency.

Strong demand for high-performance fabrics in industrial textiles, home furnishings, and technical textiles boosts the market growth in the region. In addition, the increasing demand for synthetic fibre from for fashion and sportswear is also supporting the various sectors, which in turn is fuelling the acceptance of draw heat setting winders. The increasing demand for high-quality yarn treatment and the growth of textile exports are also boosting the market growth in North America.

Germany, Italy, France, and the United Kingdom are leading in both manufacturing and usage of textile machineries in Europe, which is a mature market for draw heat setting winders. A growing focus on sustainable textile production in the region, along with the high demand for precision winding machines used in textile processing facilities, is likely to support market growth.

Increasing demand for high-performance technical textiles, automotive textiles, and home furnishings in the European textile industry is driving the application of quality yarn treatment and stabilization, contributing to the growth of the global draw heat setting winders market. In addition, the increasing adoption of energy-efficient and low-waste textile manufacturing methods in Europe has also been responsible for the growing demand for high-output qualified winding equipment with low energy consumption.

The draw heat setting winder market in Asia-Pacific is expected to grow at the fastest rate, driven by countries with significant textile production capabilities, including China, India, Bangladesh, and Vietnam. Market demand is primarily driven by the rapid growth of textile and garment manufacturing industries in the region, along with increasing demand for high-quality synthetic and blended fibre.

Asia-Pacific has become a major player in draw heat setting winders market, owing to greater investments in textile infrastructure, wide scale manufacturing for exports, and cheap labour availability. Moreover, rising consumer demand for luxury clothing, home textiles and industrial fabrics has supplemented the requirement for advanced yarn treatment technologies, propelling market growth in the region.

For instance, governments of developing countries, such as India and China, are encouraging the implementation of advanced textile machinery to enhance production efficiency, which is expected to boost the market.

Challenge

High Initial Investment Costs and Complex Machine Operations

The draw heat setting winder market is concerned about the high cost of innovation in initial machine investment. In textile and yarn production, draw heat setting winders are used on a wide scale in refining synthetic yarns, including polyester, nylon, and polypropylene, which provide high tensile strength, texture, and dimensional stability.

Nevertheless, the major hurdles are the high cost of manufacturing, installing, and maintaining these machines, which makes it a deterrent for small and medium-scale textile manufacturers. For example operating draw heat setting winders requires high skilled labour and technical knowledge, because of that operational cost for manufacturing units is increased.

Another critical pain point of this market is the energy-processing machine. This process is energy-intensive and results in high operating costs and carbon footprints. For textile manufacturers in areas with expensive energy use or strict carbon emissions legislation, that creates a headache. Frequent breakdowns or maintenance and downtimes reduces production efficiency and profitability alongside.

At present, the widespread adoption of winders in small-scale textiles industries is limited due to the lack of affordable and energy-efficient draw heat setting winders.

To address these issues, Manufacturers are increasingly turning to energy-efficient & automated draw heat setting winders that help reduce production costs while improving productivity. Moreover, offering training programs for operators and technical personnel can enhance operational efficiency, whereas leasing or financing options can facilitate investments in advanced draw heat setting winders for small-scale manufacturers.

Opportunity

An Expanding Market for High-Quality Textured Yarns and Nonwoven Fabrics

With growing preference towards high-quality textured yarns across apparel, home textiles and industrial fabric sectors, increasing demand for draw heat setting winder is expected to follow through in the coming forecast period. As global demand for stretch and durable fabrics continues to rise, manufacturers emphasize the production of thermally stabilized and textured yarns, which need effective draw heat setting winding processes.

Furthermore, the increasing adoption of synthetic types of fabric, such as polyester, polypropylene, and nylon, in sportswear, activeness wear, and performance textiles, has stimulated the demand for advanced draw heat setting winders.

Another emerging opportunity is in the increasing adoption of nonwoven fabrics for medical, hygiene, and automotive applications. Nonwoven fabrics are commonly found in disposable medical textiles, automotive interiors, and filtration media. To ensure high-tensile strength and dimensional stability, draw heat setting winders form a vital component of their production.

Furthermore, the growing trend of technical textiles for infrastructure, agriculture, and industrial applications is analysed to boost the high-performance yarns demand such as to open up other avenues of the market growth.

The development of energy-efficient models, smart control systems, and automatic yarn feeding mechanisms are technological advancements in draw heat setting winders that are providing new growth opportunities to market players.

Furthermore, with rising demand for sustainable, and low-energy textile production, the need for innovation in heat setting technologies is expected to be a key driving factor for manufacturers to invest in modernization of draw heat setting winders to deliver on evolving requirements of the industry as a whole.

The draw heat setting winder market has experienced considerable growth during the period 2020 to 2024, due to increasing demand for high-quality textured yarns for applications in apparel, home textiles and industrial. Textile manufacturers concentrated on enhancing the strength, texture, and dimensional stability of the yarn which increases the demand for effective draw heat setting winding machines.

Yet, the high upfront costs, energy consumption, and maintenance requirements were blocks to adoption particularly for small textile manufacturers.

In the coming years from 2025 to 2035, further developments will see especially ground-breaking market expansion, to a large extent propelled by the introduction of new technology and the increasing needs for energy efficiency and automation in the textile production process. With the benefits like optimized features, low operating costs, automated, low-energy, high speed draw heat setting winders, manufacturers can invest in these winders to improve efficiency.

Further, rising demands for eco-friendly and sustainable textile production applications are poised to spur innovations in low-carbon heat-setting technologies, making the draw heat setting winder market well-positioned for amplified growth.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Limited emphasis on energy efficiency in draw heat setting winders |

| Technological Advancements | Use of conventional heat setting winding machines |

| Industry Adoption | Demand for high-tensile yarns in apparel and home textiles |

| Supply Chain and Sourcing | Dependency on imported draw heat setting winding machines |

| Market Competition | Presence of traditional machinery manufacturers |

| Market Growth Drivers | Growing demand for high-quality textured yarns |

| Sustainability and Energy Efficiency | High energy consumption and carbon footprint of traditional machines |

| Integration of Smart Monitoring | Manual operation with limited process monitoring |

| Advancements in Yarn Processing | Limited automation in yarn heat setting processes |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Stricter energy efficiency regulations and low-carbon textile production norms |

| Technological Advancements | Adoption of energy-efficient, automated, and high-speed winding machines |

| Industry Adoption | Widespread use of textured yarns in technical textiles, nonwoven fabrics, and industrial textiles |

| Supply Chain and Sourcing | Increased domestic production of advanced heat setting winders |

| Market Competition | Emergence of advanced, energy-efficient winder manufacturers |

| Market Growth Drivers | Increasing demand for sustainable textiles and technical textiles |

| Sustainability and Energy Efficiency | Development of energy-efficient and low-emission draw heat setting winders |

| Integration of Smart Monitoring | Integration of real-time production monitoring and predictive maintenance |

| Advancements in Yarn Processing | Fully automated, high-speed, and programmable draw heat setting winders |

The United States Draw Heat Setting Winder Market is witnessing steady growth, aided by rising demand for high-performance textile machinery from textile and apparel manufacturers. Focus on the quality of yarn requires machines with improved efficiency, which is why the United States manufacturers are heavily investing into advanced draw heat setting winder machines.

That's not all, the increasing demand for synthetic and blended fibre manufacturing, especially in home furnishings, sportswear, and technical textiles segments also considerably contributes to the growth of the market. In the USA, renewable energy sources such as wind and solar power will reshape the energy landscape and are driving demand for energy-efficient draw heat setting winders in large-scale textile mills.

Moreover, increasing demand for recycled polyester and sustainable textiles is compelling manufacturers to improve their winding and heat-setting processes. To overcome these challenges, textile companies are collaborating with machinery manufacturers to implement high-precision winders capable of delivering superior yarn finish, providing uniform tension control and minimizing breakage.

Moreover, rising demand for technical textile from defines and automotive sectors and healthcare industries are imposing the market growth in the USA.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 4.5% |

The demand for high-quality textile manufacturing machinery in the apparel, technical textile, and home textile industries has led to a steady growth of the Draw Heat Setting Winder Market in the United Kingdom. The transition to energy-efficient practices aiming to lower energy use and decrease material waste in the yarn processing has been a driving force behind the increased deployment of advanced draw heat setting winders across India.

Also, the increasing trend for sustainable textile production (utilizing recycled fibres and environmentally friendly materials) is significant to market growth within the region.

In UK, textile manufacturers are expected to invest more in automated draw heat setting winders, as these are offering improved production efficiency, reduced power consumption, and better finishing of yarn. The increasing demand for sustainable manufacturing practices, supported by leading government initiatives, is another factor catalysing demand for advanced winding technology.

Moreover, increasing requirements for technical textiles from various industries like, automotive, construction, healthcare, etc. is expected to fuel the growth market for high-speed, high-precision draw heat setting winders.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 4.1% |

The European Union draw heat setting winder market is significantly growing with a higher demand for textile processing machinery across major textile-producing countries including Germany, Italy, and France. This transition toward sustainable production methodologies, lower carbon footprints, and better quality yarn in the region textile industry drive demand for draw heat setting winders.

Increasing utilization of automated and high-precision winding machines across textile mills is enhancing the operational efficiency, increasing the production capacity, and reducing yarn breakage.

In addition, the growth is generating momentum from the growing demand for technical textiles, non-woven fabrics, and high-performance yarns, in the European automotive, healthcare, and construction sectors. Also, textile manufacturers are focused on building winding machinery with lower energy consumption, accurate heat setting, and best yarn handling.

In addition, the growing adoption of Industry 4.0 solutions and smart manufacturing in textile mills is also contributing to increased demand for next-generation draw heat setting winders across the region.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union (EU) | 4.4% |

Japan Draw Heat Setting Winder Market Growth & Size the Draw Heat Setting Winder Market in Japan is witnessing progressive growth in the region, owing to the supportive textile manufacturing framework of the country along with the inclination towards modern and high-precision machinery.

Japanese spinning companies are focusing on energy-saving and automated draw heat setting winders to guarantee better yarn quality and to reduce production costs. The top textile industries in the country are investing in advanced winding machines to enhance operational efficiency in responding to increased consumer demand, such as synthetic fibre, technical textile, and industrial yarn production, and so on.

The increasing focus on sustainability and circular economy practices in Japan is also driving the adoption of eco-friendly textile processing machinery, including heat-setting winders. The demand for advanced draw heat setting winders in the country has also increased in recent years due to the rising utilization of high-performance fabrics in the automotive, healthcare, and electronics industries.

All these factors along with presence of prominent textile machinery manufacturer in Japan and access to innovative and efficient yarn processing solutions are further contributing to the growth market in the region.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 4.3% |

The growth of Draw Heat Setting Winder in South Korea is driven by its advancing textile and garment manufacturing industry. When yarn is processed by using high-speed, energy-efficient draw heat setting winders, South Korean textile manufacturers are able to increase the processing efficiency. The market is further enhanced by the increasing requirement for technical textiles and high-performance fabrics in the automotive, electronics, and healthcare industries.

Additionally, there is a swift uptake of technologies in South Korea, encompassing an array of innovations from smart manufacturing to AI-powered yarn processing systems, all contributing to improved operational efficiencies across South Korean textile mills.

The growing need for eco-friendly fabric production and expanding utilization of recycled fibres has further increased the demand for high yarn output, low energy consumption advanced heat-setting winders. Moreover, the growing export of technical textiles and premium quality yarn from South Korea to international markets is accelerating market growth.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 4.5% |

Draw heat setting winder in textile and technical yarn industries dominate the market, with manufacturers focusing more on precision, efficiency, and consistency for yarn winding and heat-setting processes. Draw heat setting winders are essential for accurate tension uniformity, higher strength of yarns and better dye penetration for textile and technical yarn products.

Increasing consumption of quality yarn in sectors such as apparel, home textiles, and industrial fabrics is driving the market growth, ensuring continuous demand for draw heat setting winders.

The thriving textile industry is the largest consumer of draw heat setting winders, owing to the growing demand for high quality yarn used in garments household textiles, and furnishing products. Draw heat setting winders are known for ensuring optimal performance of yarn during the process, which involves controlling yarn tension accurately, eliminating defects, and ensuring even dye penetration to enhance the quality of the final fabric.

The market has been significantly driven by the fast-paced growth of the world apparel industry, spurred on by changing fashion trends, rising consumer expenditure and demand for fast fashion at competitive prices. Furthermore, increasing consumption of home textiles, such as curtains, linens, upholstery, and floor covering, is also encouraging adoption, thus leading to prolonged usage of draw heat setting winders across textiles mills and production plants.

Growing shift towards sustainable and environment-friendly textile manufacturing practices has also influenced the demand in the market, with textile manufacturers opt for energy-efficient and waste-free yarn processing solution. The new generation of draw heat setting winders with energy-efficient motors, PLC (programmable logic controller) and real time tension control system have become preferred with lower power consumption, enhanced productivity, and improved operational efficiency.

The optimisation of winding processes using winding and heat-setting technologies with contactless yarn tension control and real-time fault detection also further increased market demand by ensuring better output quality and production times with minimal downtime owing to a building state of the art smart monitoring systems.

Furthermore, the introduction of automated and semi-automated draw heat setting winders have driven market expansion, especially in large scale textile production hubs in Asia-Pacific and Europe.

While it has benefitted from its precision yarn processing capabilities, its segment of the textile industry has also suffered due to factors like high capital expense, complex machinery maintenance, and dependency on skilled operators.

Nevertheless, evolution of fully automated draw heat setting winder systems, predictive maintenance technology, and integration of industry solutions are overcoming these challenges and guarantee the growth in the global market for textile-based draw heat setting winder systems.

The draw heat setting winder market has witnessed significant growth in the technical yarn segment due to the rising demand for high-performance and technical yarn utilized in industrial applications, such as automotive textiles, geotextiles, industrial ropes, and composite materials.

In order to achieve precise finishing, high-strength wear-resistant properties and uniform dyeing of technical yarn products, draw heat setting winders provide a decisive factor as far as the basic materials are concerned, leading to optimal material properties for industrial finishing.

The growing inclination toward automotive textiles, especially in the production of seatbelts, airbags, upholstery, and carpeting, is further propelling the growth of the market, reaffirming strong use of draw heat setting winders in technical yarn manufacturing. Additionally, the growth of construction and infrastructure activities has fuelled the demand for geotextiles such as soil stabilization fabrics, drainage materials, and erosion control products, contributing to a strong market demand.

On the other hand, the increasing demand for high-performance composite materials in aerospace, defines & industrial manufacturing is also expected to bolster the demand for the market, where technical yarn manufacturers are gradually turning towards the Draw heat setting winder solution in order to maintain uniform yarn strength, durability, and dimensional stability in their end earnings.

In addition, increasing usage of sustainable materials, ranging from bio-based yarn to recyclable technical textiles, has provided impetus to demand for heat setting winders that can handle environmentally friendly interpretations of yarn with efficiency of high order.

By combining Industry 4.0 technologies such as digital winding tension control, remote machine monitoring and data-based quality analysis, we have achieved even greater optimization in technical yarn production and have ensured that the processes are carried out at the highest efficiency, with the least possible material scrap and maximum yarn output quality.

Moreover, with the launch of modular and customizable draw heat setting winder systems, technical yarn manufacturers have been able to cater to varying production requirements, thus continuing the growth of market.

The industrial consumer threat is an important factor that impacts the growth of the technical yarn products market; however, due to the higher machinery prices, high operational complexity and regulatory compliance requirements for industrial textiles, this market segment offers a significant growth opportunity.

Nevertheless, recent rapid technology remodelling in automated winder systems, real-time production monitoring and inextricable integration with sustainable yarn processing solutions play a keen role in catering these challenges, paving the way for seamless growth of technical yarn draw heat setting winders across the globe.

Single-end and multi-end draw heat setting winder segments are anticipated to be the most lucrative segments in the draw heat setting winder market, as yarn manufacturers look for sold out, hassle-free and near to future models, to produce high-performance machineries to suit specific applications across diverse ranges of yarn processing.

Single-end draw heat setting winders have witnessed substantial adoption, especially in smaller to medium-sized textile and technical yarn manufacturers, owing to their simplicity, ease of operation, and lower upfront costs. Use of Single-end winders guarantees accurate tension control, even heat setting, and uniformity in yarn winding making them suitable for low volume and customized production of yarn.

Conversely, the multi-end draw heat setting winder segment has become a major contributor to market growth, with its proliferation amongst large-scale textile mills and industrial yarn producers, as well as technical textile manufacturers. So, multi-end winders are typically used in high volume production environments where their higher productivity, shorter operating downtime and better yarn yield really provides optimal efficiency.

Features such as modularity, automation, and digital control in multi-end draw heat setting winders have added to the market demand, allowing the manufacturers to ensure more efficient production, minimization of a material wastage and high-quality yarn. Moreover, the incorporation of predictive maintenance systems, remote operation abilities, and real-time production analysis have all bolstered the growth of the market, securing a high efficiency and profitability for yarn manufacturers.

Although there are benefits of single-end and multi-end draw heat setting winders, there are challenges still such as high costs of machinery, dependence on skilled labour, return of machinery over time and more. But ongoing developments in automated winding technology, energy-lean heat-setting solutions, and predictive maintenance tools are addressing some of these challenges, indicating an upward trajectory for single-end and multi-end draw heat setting winders globally.

The grower heat setting winder market is growing tremendously due to increasing demand for premium quality yarn production, rising use of synthetic fibres and growing textile and yarn production herb and apparel manufacturing industry in the world. The increasing demand for automated and high-speed winding machines for polyester, nylon, and other synthetic yarns has propelled the demand for draw heat setting winders.

This includes the implementation of advanced tension control systems, automated yarn splicing, and high-speed winding systems to enhance efficiency. Energy-efficient glass free winders and smart heat setting technologies are being adopted by yarn manufacturers in order to drive down operational costs while simultaneously enhancing yarn uniformity. The market is driven by the increasing number of textile production facilities in emerging economies.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| SSM Schärer Schweiter Mettler AG | 20-24% |

| Oerlikon Textile GmbH | 15-19% |

| Murata Machinery, Ltd. | 12-16% |

| Savio Macchine Tessili S.p.A | 10-14% |

| TMT Machinery, Inc. | 8-12% |

| Other Companies (combined) | 25-35% |

| Company Name | Key Offerings/Activities |

|---|---|

| SSM Schärer Schweiter Mettler AG | Offers high-performance draw heat setting winders equipped with advanced tension control systems, ensuring optimal yarn uniformity. |

| Oerlikon Textile GmbH | Specializes in high-speed automatic draw heat setting winders with energy-efficient technology for synthetic and natural yarns. |

| Murata Machinery, Ltd. | Provides advanced yarn winding systems featuring automated splicing, intelligent tension control, and high-speed winding capabilities. |

| Savio Macchine Tessili S.p.A | Offers draw heat setting winders with precise yarn control, minimizing energy consumption and enhancing productivity. |

| TMT Machinery, Inc. | Develops highly efficient draw heat setting winders designed for high-quality filament and synthetic yarn production. |

Key Company Insights

SSM Schärer Schweiter Mettler AG (20-24%)

A global leader in textile machinery manufacturing, SSM focuses on delivering high-performance draw heat setting winders with advanced yarn tension control, maximizing productivity and minimizing yarn breakage.

Oerlikon Textile GmbH (15-19%)

Oerlikon provides energy-efficient and automated draw heat setting winders for synthetic and blended yarns, reducing labor costs and improving yarn quality.

Murata Machinery, Ltd. (12-16%)

Renowned for its high-speed automatic yarn winding solutions, Murata offers draw heat setting winders equipped with intelligent splicing and tension management technology.

Savio Macchine Tessili S.p.A (10-14%)

A key player in textile machinery, Savio focuses on delivering precision-controlled draw heat setting winders that ensure consistent yarn quality and higher production output.

TMT Machinery, Inc. (8-12%)

Specializing in draw heat setting winder machines, TMT Machinery offers innovative solutions for high-quality synthetic yarn processing with enhanced heat-setting efficiency.

Other Key Players (25-35% Combined)

Several companies contribute to the draw heat setting winder market by providing customized solutions for textile manufacturing, efficient yarn processing, and automation. These include:

The overall market size for the Draw Heat Setting Winder Market was USD 16,349 million in 2025.

The Draw Heat Setting Winder Market is expected to reach USD 24,670 million in 2035.

The growing demand for high-quality yarn in the textile and technical fabric industry, increasing adoption of advanced heat-setting winding technology, and rising industrialization in emerging economies fuel the Draw Heat Setting Winder Market during the forecast period. The expanding textile manufacturing capacity and demand for technical yarn also accelerate market growth.

The top 5 countries driving the development of the Draw Heat Setting Winder Market are China, India, the United States, Germany, and Japan.

On the basis of application, Textile and Technical Yarn Industries are expected to command a significant share over the forecast period, driven by increasing demand for uniform yarn quality, advanced yarn processing technologies, and growing investments in textile manufacturing infrastructure.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Heat Exchanger Inspection Service Market Size and Share Forecast Outlook 2025 to 2035

Heat-Treated NiTi Endodontic File Market Size and Share Forecast Outlook 2025 to 2035

Heated Sampling Composite Tube Market Size and Share Forecast Outlook 2025 to 2035

Heat Seal Film Market Size and Share Forecast Outlook 2025 to 2035

Heat Shrink Fitting Machines Market Size and Share Forecast Outlook 2025 to 2035

Heat Detachable Tape Market Size and Share Forecast Outlook 2025 to 2035

Heat Induction Cap Liner Market Size and Share Forecast Outlook 2025 to 2035

Heat Pump Market Size and Share Forecast Outlook 2025 to 2035

Heat Transfer Film Market Size and Share Forecast Outlook 2025 to 2035

Heater-Cooler Devices Market Size and Share Forecast Outlook 2025 to 2035

Drawplate Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Heat Treating Market Size and Share Forecast Outlook 2025 to 2035

Heating Agents Market Size and Share Forecast Outlook 2025 to 2035

Heat Diffuser Market Size and Share Forecast Outlook 2025 to 2035

Heat Pump Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Heat Pump Compressors Market Size and Share Forecast Outlook 2025 to 2035

Heat-Activated Beauty Masks Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Heat Exchanger Market Size and Share Forecast Outlook 2025 to 2035

Heat Sealable Packaging Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA