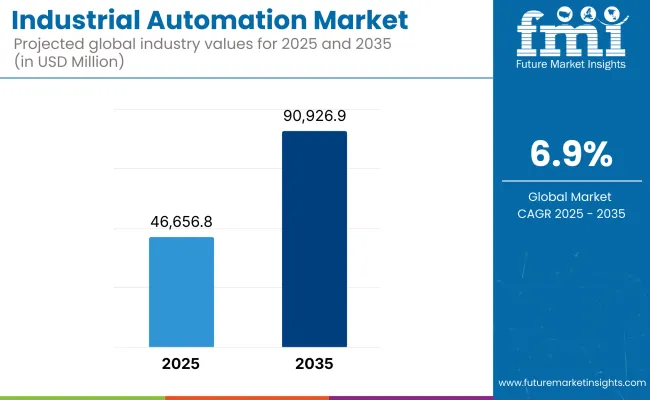

The industrial automation market is projected to experience robust growth from 2025 to 2035, driven by the rise of smart manufacturing, the increasing adoption of Industry 4.0 principles, and the growing need for operational efficiency across industrial sectors. The market is expected to be valued at USD 46,656.8 million in 2025 and is anticipated to reach USD 90,926.9 million by 2035, reflecting a CAGR of 6.9% over the forecast period.

Industrial automation is the use of control systems, robotics, and data technologies to operate equipment in an industry without human intervention. Main advantages of robotics include increased productivity, lower labour costs, higher safety and data-driven decision making.

Despite the continued expansion of automation adoption, high capital investment, complexity in integrating, and cyber security threats are still major challenges across the global markets.

Its emerging trends include edge computing-based industrial computing, digital twin technology, AI-based predictive maintenance, and cyber-physical systems to optimize processes in real-time. This is accelerating adoption further because of the shift toward autonomous production environments and low-code automation platforms.

North America stays to be one of the maximum dominating and performance-orientated areas with inside the marketplace of commercial automation, owing to sturdy investments in clever manufacturing facility infrastructure, robotics, and cloud-based manufacturing software.

In the USA, notable adoption is being observed, especially across various industry verticals such as automotive, aerospace, oil & gas, and other sectors, where AI-based Quality Control and digital supply chain integration are gaining traction form. Canada invests in energy efficiency through automation and sustainable industrial transformation.

With developed industrial capabilities, robust regulatory frameworks, and a push for sustainability and productivity improvements, Europe is still a bastion for industrial automation. Facts Germany, France, Italy and UK are frontrunners in adopting collaborative robots (cobots), green automation and 5G-enabled industrial systems. Demand for more flexible, sustainable, more worker-centric automation technologies is driven by the EU Green Deal and Industry 5.0 initiatives.

The region of Asia-Pacific leads in the most rapidly growing region, driven by production centers such as China, India, Japan, South Korea and Southeast Asia. To note, China is significantly increasing automation within electronics, automotive, and heavy industries, and India is effectively utilizing automation within their pharmaceuticals, textiles, and logistics.

The robotics innovation of Japan and South Korea, along with AI automation and requirements for precision. Regional growth continues to be supported by government incentives, rising labour costs, and export-driven industrialization.

Challenges: High Capital Investment and Cybersecurity Risks

Although automation can save costs in the long run, it is a very expensive investment in the short term, particularly in industries with a lot of legacy infrastructure.

Integration with legacy systems, talent shortages, and cybersecurity vulnerabilities spanning entire connected factory environments remain areas of risk. In some areas, resistance to change and a lack of digital maturity can slow adoption as well.

Opportunities: Industry 4.0, AI Integration, and Smart Manufacturing

These include integrated AI, IoT, 5G, and cloud computing, which allow for real-time monitoring, making autonomous decisions, and operating a plant remotely. And it is growth in modular automation platforms, plug-and-play robotics and AI-based optimization tools is unlocking productivity gains in industries everywhere.

Emerging trends such as digital twin ecosystems, sustainability-linked automation, and self-healing manufacturing systems are contributing to reshaping the global industrial landscape.

With the growth of smart manufacturing, labour shortages, and the global drive to develop resilient supply chains in a post COVID-19 world, the Industrial Automation Market is expected to witness the Corridor boom between 2020 and 2024. IL growth was driven by the adoption of Robotics, Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and Industrial Internet of Things (IIoT) technologies.

These automation systems resulted in reduced costs, improved efficiency in production, and predictive maintenance. Nevertheless, challenges such as high initial investment costs, legacy system integration systems, and cybersecurity risks remained obstacles to the widespread adoption of automation in traditional industries.

In 2025 to 2035, AI-based autonomous manufacturing and digit twin simulation, machine communication enabled by 5G (fifth generation) technology, and Control systems at the Edge will change the market.

Quantum computing, green automation technologies and distributed production systems will blend with cyber-physical systems. Self-regulating factories with real-time decision-making, greener automation practices, and even AI-led quality control are anticipated to be the fabric of smart factories.

When blended with technological divisions in manufacturing, macro consumer trends like low-code industrial automation platforms, robotics-as-a-service (RaaS) and blockchain-powered supply chain visibility will transform how industries track productivity, safety and the carbon footprint.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Compliance with OSHA, IEC 61508, ISO 13849, and sector-specific safety standards. |

| Technological Innovation | Growth in PLCs, SCADA systems, robotics, and IIoT sensor integration. |

| Industry Adoption | Adoption in automotive, electronics, packaging, and food & beverage sectors. |

| Smart & AI-Enabled Solutions | Use of AI for predictive maintenance, basic defect detection, and energy optimization. |

| Market Competition | Dominated by Siemens, ABB, Rockwell Automation, Mitsubishi Electric, and Schneider Electric. |

| Market Growth Drivers | Demand for operational efficiency, workforce shortages, and supply chain automation. |

| Sustainability and Environmental Impact | Energy-efficient drive systems, carbon reduction through automation, and digital waste tracking. |

| Integration of AI & Digitalization | Basic AI tools, digital dashboards, and centralized control systems. |

| Advancements in Product Design | Modular and interoperable PLCs, robotic arms, and HMI software suites. |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Stricter global AI-in-manufacturing regulations, automated safety audits, and ESG-aligned operational compliance via AI/NLP platforms. |

| Technological Innovation | Emergence of self-optimizing autonomous factories, AI-driven robotic swarms, and real-time digital twin environments. |

| Industry Adoption | Expansion into space tech, modular micro factories, AI-enhanced bio manufacturing, and climate tech manufacturing systems. |

| Smart & AI-Enabled Solutions | Full integration of AI for autonomous process optimization, anomaly detection, and generative design in production workflows. |

| Market Competition | Increased competition from AI-first automation startups, open-source robotics platforms, and edge-cloud hybrid automation providers. |

| Market Growth Drivers | Growth driven by self-healing production lines, resilient global manufacturing, and ESG-compliant automation solutions. |

| Sustainability and Environmental Impact | Rise of carbon-neutral automation systems, AI for circular manufacturing, and smart grid-integrated production processes. |

| Integration of AI & Digitalization | AI-native control layers, decentralized edge decision-making, and blockchain-enabled machine identity and data trust systems. |

| Advancements in Product Design | Plug-and-play AI robotics, software-defined automation stacks, and no-code/low-code industrial workflow builders. |

The industrial automation market in the USA is growing at a rapid pace, driven by the manufacturing sector's need for efficiency, optimizing the labour force, and supporting supply chain resilience. Popular adoption of robotics, PLCs, SCADA systems, and AI-based predictive maintenance tools are revolutionizing conventional operations.

Demand is especially high in automotive, food processing, pharmaceuticals and aerospace sectors. Also, government incentives to reshore manufacture, plus investment in smart factories, are accelerating the application of Industry 4.0 technology. Recently, interoperability, cybersecurity and edge computing in a USA-based automation model has become essential.

| Country | CAGR (2025 to 2035) |

|---|---|

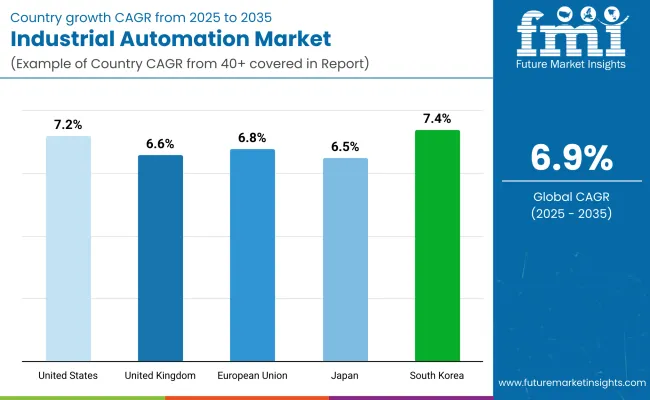

| United States | 7.2% |

The UK industrial automation market is on a growth trajectory as manufacturers ramp up their digitization efforts in a post-Brexit landscape. Automation helps small and mid-size enterprises (SMEs) stay competitive and gain traction, especially in industries such as automotive, packaging and electronics.

The likes of collaborative robots (cobots), vision systems and AI-enabled quality control solutions are on the rise. Innovation hubs backed by government funding, as well as investment in advanced manufacturing, are accelerating adoption as well. Energy efficiency and material waste reduction are also driving automation upgrades to meet sustainability targets.

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 6.6% |

Germany, France, and Italy remain the top three players in the EU industrial automation market, supported by strong engineering ecosystems and early uptake of Industry 4.0 technologies. Manufacturers of automotive, electronics, and heavy machinery, however, are ultimately investing extensively in emerging technologies like robotics, IoT platforms, and MES integration.

The EU’s green transition strategy needs to push factories to embrace automation solutions that help the efficiency of energy use, predictive maintenance, emission control etc. Cross border co-operation and standardisation initiatives help streamline digital platforms across the bloc to allow for cost-effective data sharing and scalability.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 6.8% |

Japan’s market for industrial automation is among the world’s largest, owing to dwindling workers, elevated labour costs and high precision manufacturing demands. Robotics is at the heart of it, with advanced applications for electronics, automotive and medical device manufacturing.

Smart sensor integration, real-time analytics, and adaptive control systems these are the Japanese manufacturers that are focusing on to improve productivity. Government initiatives to promote the merging of the AI and IoT to industrial environments also Lightweight cobots and mobile robotic systems are also solidifying their presence in logistics and warehousing.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 6.5% |

The industrial automation market is booming in South Korea, driven by strong investment in semiconductor manufacturing, consumer electronics and EV production. The country is widely considered a leader in smart factory deployment, utilizing 5G, edge computing, and artificial intelligence to optimize processes in real time.

Big and small Korean companies are automating their production lines, warehouses and QA systems to be more competitive. Government programs encourage automation upgrades, especially for SMEs. Rising demand for integrated software-hardware automation solutions across discrete and process industries

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 7.4% |

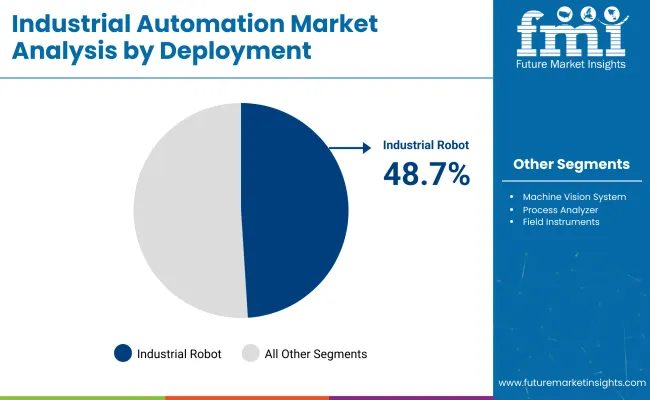

Deployment Market Share (2025)

| Deployment | Value Share (%) |

|---|---|

| Industrial Robots | 48.7% |

After 2025, the market of Industrial Automation will be 48.7% of the total value share will be taken by Industrial robots. Their significance is amplified due to the increasing demand for accuracy, speed, and reliability in manufacturing processes, such as those in automotive, electronics, metal, and food & beverage industries.

Industrial robots are known for their adaptability they can weld and assemble products, as well as package and palletize them, making them essential for today’s production environments.

The emergence of collaborative robots (cobots), which are designed to work safely alongside human operators, has greatly expanded the range of options for automation in small- and medium-sized enterprises. They extend operational flexibility, minimize labour-intense work, and eliminate production downtime.

Moreover, AI and machine learning innovations are providing more intelligent features such as adaptive decision-making, predictive maintenance, and real-time performance optimization.

Combining Industry 4.0's drive and the worldwide labour deficit with increasing labour costs contributes immensely to industrial robots supremacy. These robots have become an indispensable component for the future of manufacturing due to their exceptional scalability, efficiency, and operational capabilities in hazardous environments.

Moreover, initiatives by governments fostering smart manufacturing and automation have contributed to the global adoption of industrial robots.

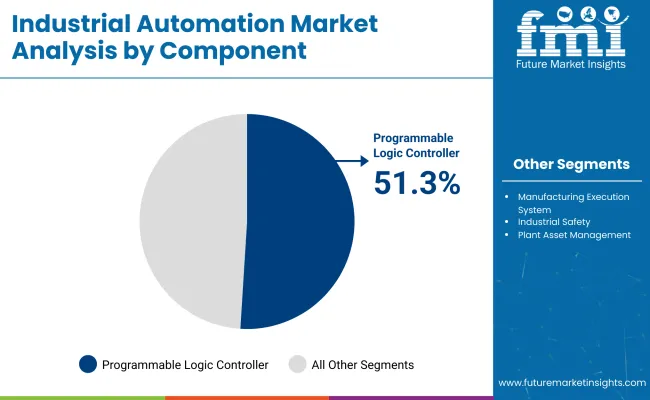

Component Market Share (2025)

| Component | Value Share (%) |

|---|---|

| Programmable Logic Controller | 51.3% |

Programmable Logic Controller (PLC) is expected to be the major component in the industrial automation market with a value share of 51.3% by 2025. PLCs are famous for their resilience, flexibility, and seamless ability to integrate with other tools and systems; they are the backbone of automation systems, running everything from the control of a single machine to more elaborate, high-powered production that involves many stages of production.

Due to their real-time processing abilities, compatibility with a multitude of sensors, actuators and interface systems, these controllers are additionally widely implemented among industries. In response to the growing complexity and interconnectedness of modern manufacturing environments, PLCs are continuing to evolve with features such as Ethernet/IP communication, advanced diagnostics, and remote monitoring to support smart factory initiatives.

Modern PLCs consist of a core processor with a basic input/output configuration and operate on a modular architecture to allow for low-cost customization and scalability, making them suitable for both discrete as well as process automation. Thus, they are the backbone of automation infrastructure, keeping production continuity, lowering errors rate and increasing efficiency.

Next generation PLCs are also incorporating Industrial IoT, Edge Computing and Cyber Security, providing enhanced intelligence and security. With continued investment and technological improvements, PLCs are likely to lead the industrial automation market, as automation becomes more important for resilience and competitiveness, the research firm noted.

The industrial automation market is witnessing rapid growth, driven by the increasing need for operational efficiency, real-time monitoring, and predictive maintenance across various sectors such as manufacturing, energy, automotive, and logistics.

The ongoing revolution in production environments is coming from using automation solutions that integrate robotics, PLC systems, industrial IoT, and AI-driven analytics. Key drivers include Industry 4.0, labour cost efficiency, smart factory expansion, investments in digital twins & cyber-physical systems.

Market Share Analysis by Key Players

| Company/Organization Name | Estimated Market Share (%) |

|---|---|

| Siemens AG | 16-20% |

| Rockwell Automation, Inc. | 13-17% |

| Schneider Electric SE | 12-16% |

| Mitsubishi Electric Corporation | 10-14% |

| ABB Ltd. | 9-12% |

| Others | 22-28% |

| Company/Organization Name | Key Offerings/Activities |

|---|---|

| Siemens AG | In 2024, Siemens launched its next-gen SIMATIC Automation X platform with edge computing and AI integration, enabling adaptive control for dynamic manufacturing environments. |

| Rockwell Automation, Inc. | As of 2023, Rockwell expanded its FactoryTalk® Design Hub, offering cloud-native automation design tools for system integrators and OEMs. |

| Schneider Electric SE | In 2025, Schneider introduced EcoStruxure Automation Expert 2025, an open, software-defined automation platform for modular and distributed production lines. |

| Mitsubishi Electric Corporation | In 2023, Mitsubishi Electric enhanced its iQ-R Series PLCs with integrated cybersecurity protocols and real-time process simulation capabilities. |

| ABB Ltd. | As of 2024, ABB launched OmniCore™ automation controllers optimized for multi-axis robotics and IIoT connectivity in discrete manufacturing environments. |

Key Market Insights

Siemens AG (16-20%)

Leads the market with end-to-end industrial automation solutions that combine hardware, software, and edge-AI to support flexible and autonomous production.

Rockwell Automation, Inc. (13-17%)

Focuses on connected enterprise solutions with strong offerings in control systems, digital twins, and cloud-based automation platforms.

Schneider Electric SE (12-16%)

Champions software-centric automation with a focus on energy-efficient, open-architecture systems for hybrid and discrete industries.

Mitsubishi Electric Corporation (10-14%)

Offers robust automation hardware and simulation software with strong market presence in Asia-Pacific and growing footprint in North America.

ABB Ltd. (9-12%)

Specializes in robotics, motion control, and smart sensor integration, driving efficiency in high-throughput and lights-out manufacturing operations.

Other Key Players (Combined Share: 22-28%)

A diverse group of regional and specialized companies is contributing through innovations in automation software, industrial AI, cobots, and sector-specific control systems, including:

The overall market size for the industrial automation market was USD 46,656.8 million in 2025.

The industrial automation market is expected to reach USD 90,926.9 million in 2035.

The demand for industrial automation will be driven by increasing adoption of Industry 4.0 technologies, rising need for operational efficiency and cost reduction, growing use of robotics and smart manufacturing systems, and advancements in AI, IoT, and machine vision technologies.

The top 5 countries driving the development of the industrial automation market are the USA, China, Germany, Japan, and South Korea.

The programmable logic controllers (PLCs) segment is expected to command a significant share over the assessment period.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Factory Automation And Industrial Controls Market Growth - Trends & Forecast 2025 to 2035

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Industrial Pepper Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronics Packaging Market Forecast and Outlook 2025 to 2035

Industrial Absorbent Market Forecast and Outlook 2025 to 2035

Industrial Furnace Industry Analysis in Europe Forecast and Outlook 2025 to 2035

Industrial Denox System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronic Pressure Switch Market Size and Share Forecast Outlook 2025 to 2035

Industrial WiFi Module Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA