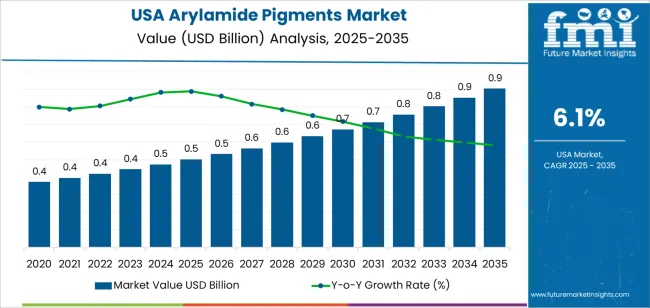

The demand for arylamide pigments in USA is expected to grow from USD 0.5 billion in 2025 to USD 0.9 billion by 2035, reflecting a CAGR of 6.1%. The growth in the arylamide pigments industry is driven by several factors, including the expanding high-performance colorant applications, the rising adoption of heat-resistant formulations, and the growing complexity of industrial coating requirements. With manufacturers focusing on color fastness and chemical resistance, arylamide pigments provide essential chromatic properties while enabling advanced formulation processes that meet stringent performance specifications.

The growth is also driven by advancements in synthetic chemistry, increased demand for lightfast colorants requiring specialized dyeing solutions, and the broadening of pigment applications across printing, automotive, and plastic systems. The rising adoption of digital printing technologies and the expansion of specialty coating formulations will support the growth. The increasing focus on color consistency standards and fade-resistant properties among industrial formulators also adds to the demand for arylamide pigments, which offer both chromatic intensity and chemical stability without the performance limitations of conventional organic colorants.

The analysis for arylamide pigments in USA reveals that the industry is expected to experience significant expansion over the forecast period from 2025 to 2035. The industry will grow from USD 0.5 billion in 2025 to USD 0.9 billion in 2035, reflecting an increase of USD 0.4 billion over the next decade. This growth indicates a strong expansion of the arylamide pigments sector, with more formulators opting for high-performance colorant solutions rather than conventional organic dyes.

From 2025 to 2030, the industry will grow from USD 0.5 billion to USD 0.7 billion, contributing USD 0.2 billion in growth. This phase will see an initial gain in adoption as more manufacturers embrace lightfast pigment systems, driven by an increasing interest in color durability and chemical resistance. The demand for yellow arylamide formulations, particularly for printing and coating applications, will contribute significantly to this growth.

From 2030 to 2035, the industry will expand from USD 0.7 billion to USD 0.9 billion, contributing USD 0.2 billion in growth. This phase will see stronger expansion as pigment technology becomes more sophisticated, with more formulators choosing specialized arylamide solutions for plastics, textiles, and advanced coating systems. With more chemical suppliers and manufacturers embracing arylamide-based formulation methods, the industry is expected to capture a larger share of the overall specialty chemicals sector, particularly among manufacturers focused on color performance and chemical resistance optimization. The strong growth momentum in the latter half of the forecast period reflects the maturation of the industry, where arylamide solutions become an integrated part of mainstream industrial formulation in USA.

| Metric | Value |

|---|---|

| Industry Sales Value (2025) | USD 0.5 billion |

| Industry Forecast Value (2035) | USD 0.9 billion |

| Industry Forecast CAGR (2025-2035) | 6.1% |

Demand for arylamide pigments in USA is rising as formulators increasingly embrace high-performance colorants over conventional organic dyes, driven by lightfastness requirements and the desire for chemically resistant formulations at competitive cost structures. Many manufacturers, especially those producing industrial coatings, prefer arylamide-based colorant systems for printing applications, plastic coloration, and coating formulations instead of traditional dyes that may fade quickly or require frequent reformulation.

Chemical suppliers offering standardized arylamide systems, technical support partnerships, and pre-tested formulations support this shift by providing color consistency, thermal stability, and formulation flexibility. Industrial formulators and suppliers are collaborating with pigment specialists to optimize colorant lifecycles and enhance production reliability, which drives adoption. Industry data show that the USA arylamide pigments sector is valued at approximately USD 0.5 billion and is expected to grow steadily.

Another key factor is the convergence of printing technology trends, regulatory compliance requirements, and the performance-driven mindset. Formulators increasingly seek to experiment with color systems, follow industry-driven specification changes, and minimize formulation complexity, which make arylamide solutions attractive. Advances in pigment dispersion, surface treatment technologies, and digital formulation platforms reduce friction in arylamide integration processes and improve color reliability, which encourages broader acceptance.

Challenges remain: managing pigment compatibility across multiple substrates, ensuring color matching and consistency in a performance-critical environment, and maintaining operational profitability amid raw material and processing costs. Despite these headwinds, as formulation methods shift toward performance and reliability, the demand for arylamide pigments in USA is projected to continue its upward trajectory.

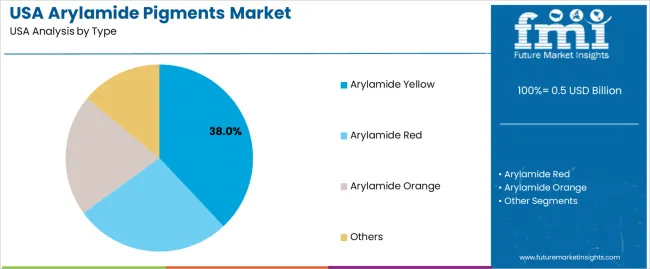

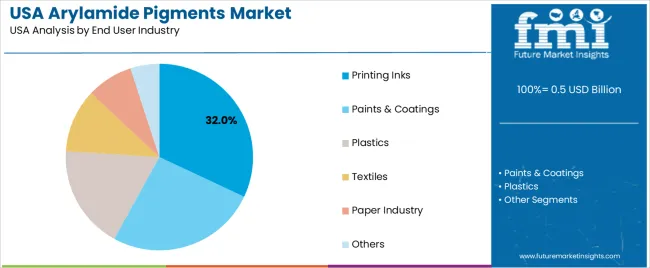

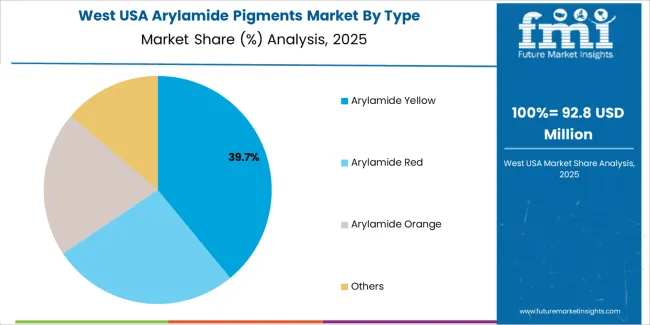

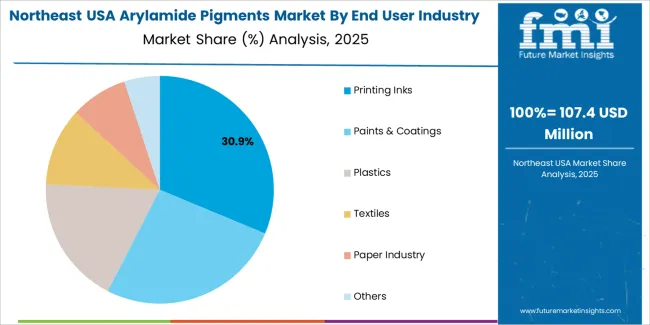

The demand for arylamide pigments in USA is primarily driven by type and end user industry. The leading type is arylamide yellow, which holds 38% of the share, while printing inks is the dominant end user industry segment, accounting for 32.0% of the demand. Arylamide pigments have gained significant traction in both the industrial and commercial sectors due to their performance advantages, color stability benefits, and the growing trend of high-performance colorant formulation. The arylamide approach allows formulators and end users to access superior colorant properties without the need for complex stabilization systems, which appeals to various industrial environments.

Arylamide yellow is the leading type in the arylamide pigments sector, capturing 38% of the share. The increasing popularity of bright, lightfast yellow colorants for applications such as printing inks, automotive coatings, and plastic colorations has driven demand for these compounds in the pigment space. Using arylamide yellow allows formulators to access high-intensity, thermally stable yellow properties for critical coloration applications without the significant cost of developing custom colorant systems.

In USA, where color performance standards are prominent, pigment solutions for arylamide yellow applications have become an attractive alternative for formulators seeking effective, standardized yellow colorants. Using arylamide yellow for graphics, industrial coatings, and plastic coloration applications also supports the growing trend of performance-based formulation, as these pigments are often specified multiple times across different substrate platforms. As formulators continue to prioritize color consistency and thermal stability in industrial applications, the demand for arylamide yellow solutions is expected to remain strong, positioning it as a dominant category in the arylamide pigments sector.

Printing inks are the leading end user industry for arylamide pigments in USA, capturing 32.0% of the share. In the printing inks application space, manufacturers, particularly those in the commercial printing sector, are increasingly turning to arylamide solutions for offset printing, flexographic systems, and digital printing formulations. Printing ink applications benefit from arylamide solutions by ensuring precise color reproduction and lightfastness for graphic applications, without the need for large investments in custom colorant development or concerns about color migration.

Arylamide pigment solutions also offer manufacturers the flexibility to adapt or modify their ink formulations for different substrates or for specific printing applications, which can enhance the versatility of their production capabilities without the complexity of managing multiple colorant inventories. The growing emphasis on print quality and reducing color variability has driven many manufacturers to seek arylamide solutions, which align with their quality assurance goals. As the printing sector continues to embrace reliable, consistent, and high-performance colorant practices, the demand for arylamide pigment solutions is expected to grow, solidifying its position as the dominant segment in the industry.

Demand for arylamide pigments in the USA is rising as formulators increasingly prioritize color performance over conventional dye systems, driven by lightfastness concerns, rapid application changes, and technology-enabled pigment platforms. Growth stems from standardized colorant systems, on-demand formulation access, and regulatory-driven color requirements. Operational challenges like raw material sourcing, pigment compatibility, and formulator reluctance to change established color systems are restraining expansion. Key trends include interactive color matching software tools, supplier-direct pigment models, and the shift of arylamide solutions into mainstream industrial formulation rather than just specialty or high-performance applications.

Several factors support growth in the USA chemical sector. First, younger formulation teams (millennials and Gen Z professionals) demonstrate strong interest in color performance, lightfast properties, and cost-effective access to engineered pigments, driving arylamide adoption. Second, the proliferation of color matching software, e-commerce platforms, and supplier integration services simplifies arylamide pigment sourcing and enhances formulation convenience.

Third, performance imperatives such as reducing color fading, extending product lifecycles, and optimizing formulation workflows boost arylamide adoption among quality-aware manufacturers. Fourth, applications and formulation requirements (new product launches, substrate compatibility, color consistency optimization) continue to fuel demand for higher-performance colorants on a specification basis rather than commodity dye alternatives.

Despite momentum, several restraints inhibit growth. Customer concerns about pigment compatibility, color matching accuracy, and performance consistency of arylamide systems may limit adoption among more conservative formulators. The cost structure of arylamide solutions, including pigment acquisition, dispersion processing, quality testing, and technical support can reduce margins and raise total formulation costs, making the offering less compelling versus conventional dyes for some applications. The arylamide category remains specialized compared to total colorant consumption, and many formulators continue to prefer established dye systems. Operational complexity, including supplier management and technical support requirements, adds risk for production facilities.

Major trends include the move from specialty-application pigments to broader formulation solutions covering standard printing, coating systems, and everyday coloration requirements. There is increasing integration of technology such as virtual color matching, AI-driven pigment selection, and personalized formulation specifications, improving user experience and reducing compatibility-related issues. Supplier-direct pigment platforms are emerging, enabling formulators to source colorants directly from pigment specialists and expanding the sector beyond traditional distributor channels only. Chemical manufacturers and pigment platforms are also consolidating with traditional colorant suppliers, offering hybrid standard-and-custom solutions, and promoting high-performance credentials to appeal to quality-conscious formulation teams.

The demand for arylamide pigments in USA is growing as formulators increasingly seek lightfast, chemically resistant, and cost-effective options for industrial coloration. Arylamide pigment solutions allow production facilities to achieve high-performance, engineered colorants for a fraction of the custom development cost, reducing the need for complex color stabilization and promoting more reliable formulation. This approach is particularly attractive to formulators who want access to a wide variety of colorant properties without the commitment of long-term development investments. Factors driving this demand include the rise in color performance focus, the popularity of specification-driven formulation, and the growing trend of performance-based colorant selection methods.

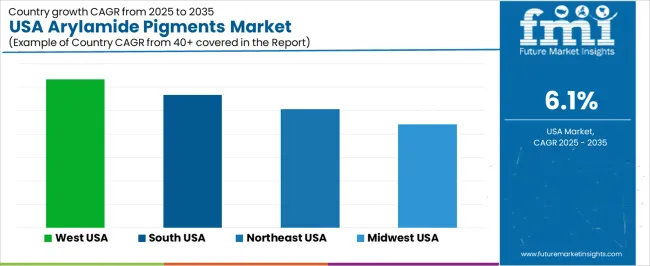

The increasing focus on conventional dyes' lightfastness and stability limitations is encouraging formulators to seek more reliable alternatives, like arylamide systems. Regional demand varies depending on factors such as industrial concentration, printing trends, and access to technical support networks. The West USA leads in demand, supported by higher technology adoption and innovation-focused formulation facilities, while the South USA, Northeast USA, and Midwest USA show steady adoption driven by shifting formulation behavior towards more reliable and cost-effective colorant choices. This analysis explores the factors shaping the demand for arylamide pigments across the USA.

| Country | CAGR (2025-2035) |

|---|---|

| West USA | 6.3% |

| South USA | 5.7% |

| Northeast USA | 5.1% |

| Midwest USA | 4.4% |

The West USA region leads the USA in the demand for arylamide pigments with a CAGR of 6.3%. The region's large chemical presence, particularly in cities like Los Angeles, San Francisco, and Seattle, is highly attuned to formulation innovation and color performance, both of which drive the demand for arylamide pigment solutions. California, known for its technology-forward formulators, is a key geography where the demand for reliable and cost-effective coloration is growing.

The West USA also has a higher concentration of technology-oriented facilities who are comfortable with performance platforms and advanced formulation models. With the region's focus on color optimization, arylamide pigments offer a viable alternative to conventional dyes, enabling formulators to access high-performance colorant solutions for various applications without the operational cost of complex color development. As the demand for versatile and reliable colorant options continues to rise in the West USA, the region remains the leading geography for arylamide solutions.

The South USA shows strong demand for arylamide pigments with a CAGR of 5.7%. The region's increasing focus on formulation efficiency, combined with a growing interest in color innovation, contributes to the rising adoption of arylamide solutions. States like Texas, Florida, and Georgia have large chemical manufacturing populations and emerging formulation capabilities, making them key drivers of demand for reliable and consistent colorant solutions.

The growing chemical base in the South USA, with its higher production volumes and increasing awareness of the performance impact of conventional dyes, supports the demand for arylamide pigments. The reliability factor, coupled with the trend toward performance-based coloration instead of traditional dye systems, is appealing to many formulators in the South USA. With the rise of specification-driven formulation and shifting color preferences, the South USA is expected to continue to see strong demand for arylamide solutions.

The Northeast USA demonstrates steady demand for arylamide pigments with a CAGR of 5.1%. The region, home to major chemical centers like New York and Boston, has a high concentration of formulation-focused manufacturers who are increasingly turning to arylamide solutions for high-performance, reliable colorant systems. The Northeast USA's emphasis on quality, combined with growing performance awareness, is driving the adoption of advanced coloration solutions.

The high cost of formulation in major manufacturing cities like New York makes arylamide pigments an attractive option for facilities seeking variety in their colorant methods without the substantial cost of developing custom dye systems. While growth is steady compared to the West USA and South USA, the Northeast USA's formulation-focused population and strong chemical infrastructure ensure that the demand for arylamide pigments remains a key part of the coloration landscape.

The Midwest USA shows moderate growth in the demand for arylamide pigments with a CAGR of 4.4%. While the region may not be as innovation-focused as the West USA or Northeast USA, there is a growing interest in more reliable and consistent colorant choices. Cities like Chicago, Detroit, and Minneapolis are seeing an increasing number of formulators turning to arylamide pigment solutions as they seek alternatives to conventional dyes and want to reduce their color variability.

The Midwest USA's steady adoption of arylamide solutions is driven by the growing desire for formulation reliability and the availability of more pigment platforms that cater to diverse manufacturing needs. As the awareness of the performance benefits of arylamide solutions increases and formulators seek more reliable, consistent colorant solutions, demand for these components will continue to grow in the Midwest USA, albeit at a slower pace compared to other regions.

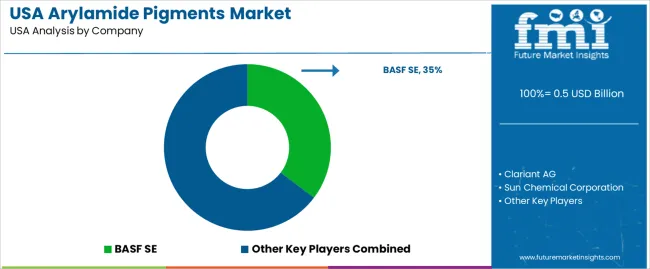

The arylamide pigments industry in the United States is growing as formulators increasingly seek more reliable and cost-effective colorant options. Companies such as BASF SE (holding approximately 35.3% share), Clariant AG, Sun Chemical Corporation, DIC Corporation, and Heubach GmbH are key players in this industry, providing customers with access to high-performance, engineered colorant solutions for short-term and long-term use. The rise of specification-driven formulation, growing performance awareness, and the desire for reliability without the commitment of custom color development are all driving factors behind the sector's expansion.

Competition in the arylamide pigments industry is centered around colorant performance, technical service, and pricing flexibility. Companies focus on offering a wide selection of colorant solutions, from basic pigments to complex formulation systems, and expanding their application ranges to cater to a broader customer base. Another competitive advantage is consistency, with many companies offering standardized systems, rapid delivery, and easy integration.

Some players are also emphasizing technical practices, such as the use of advanced dispersion methods and the promotion of performance-based formulation. Marketing materials typically highlight colorant performance, convenience of integration process, and the cost-effectiveness of access to high-end pigment solutions. By aligning their offerings with the growing demand for reliability, convenience, and performance, these companies are positioning themselves to lead the USA arylamide pigments industry.

| Items | Details |

|---|---|

| Quantitative Units | USD Billion |

| Regions Covered | USA |

| Type | Arylamide Yellow, Arylamide Red, Arylamide Orange, Others |

| End User Industry | Printing Inks, Paints & Coatings, Plastics, Textiles, Paper Industry, Others |

| Key Companies Profiled | BASF SE, Clariant AG, Sun Chemical Corporation, DIC Corporation, Heubach GmbH |

| Additional Attributes | Dollar sales by type and end-use industry define the sector, with USA demand rising for arylamide pigments across industrial and commercial applications. Competition centers on formulation capability, color reliability, platform innovation, and expanding high-performance pigment integration options. |

The demand for arylamide pigments in USA is estimated to be valued at USD 0.5 billion in 2025.

The market size for the arylamide pigments in USA is projected to reach USD 0.9 billion by 2035.

The demand for arylamide pigments in USA is expected to grow at a 6.1% CAGR between 2025 and 2035.

The key product types in arylamide pigments in USA are arylamide yellow, arylamide red, arylamide orange and others.

In terms of end user industry, printing inks segment is expected to command 32.0% share in the arylamide pigments in USA in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Arylamide Pigments Market Growth - Trends & Forecast 2025 to 2035

USA Medical Coding Market Size and Share Forecast Outlook 2025 to 2035

USA Labels Market Size and Share Forecast Outlook 2025 to 2035

USA Plant-based Creamers Market Size and Share Forecast Outlook 2025 to 2035

USA Barrier Coated Paper Market Size and Share Forecast Outlook 2025 to 2035

USA Electronic Health Records (EHR) Market Size and Share Forecast Outlook 2025 to 2035

USA Animal Model Market Size and Share Forecast Outlook 2025 to 2035

USA and Canada Packer Bottle Market Size and Share Forecast Outlook 2025 to 2035

USA Stretch Hood Films Market Size and Share Forecast Outlook 2025 to 2035

USA and Canada Fence Screen Market Size and Share Forecast Outlook 2025 to 2035

USA Lubricant Contaminated HDPE Container Waste Market Size and Share Forecast Outlook 2025 to 2035

USA Commercial Walk-In Refrigeration Market Size and Share Forecast Outlook 2025 to 2035

USA & Canada Pre-painted Steel Roofing and Cladding Market Size and Share Forecast Outlook 2025 to 2035

USA Residential Cotton Candy Maker Market Size and Share Forecast Outlook 2025 to 2035

USA Faith Based Tourism Market Size and Share Forecast Outlook 2025 to 2035

United States NFC Lemon Juice Market Analysis - Size, Growth and Forecast 2025 to 2035

USA and Canada Copper Market Insights - Demand, Size & Industry Trends 2025 to 2035

USA Ground and Precipitated Calcium Carbonate Market Growth by Product Type, Application, End-Use, and Region in 2025 to 2035

United States Animal Feed Additives Market Report – Trends, Growth & Forecast 2025–2035

United States Wild Rice Market Outlook – Size, Demand & Forecast 2025–2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA