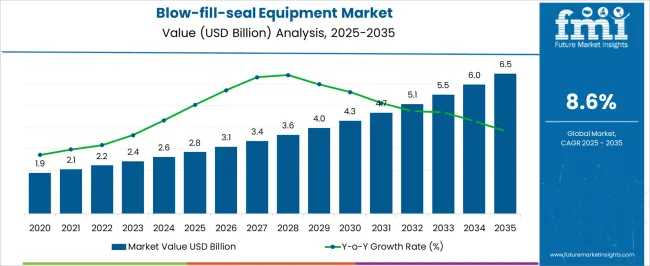

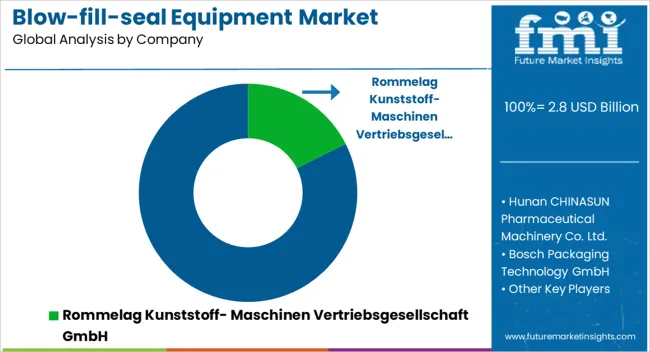

The Blow-fill-seal Equipment Market is estimated to be valued at USD 2.8 billion in 2025 and is projected to reach USD 6.5 billion by 2035, registering a compound annual growth rate (CAGR) of 8.6% over the forecast period.

| Metric | Value |

|---|---|

| Blow-fill-seal Equipment Market Estimated Value in (2025 E) | USD 2.8 billion |

| Blow-fill-seal Equipment Market Forecast Value in (2035 F) | USD 6.5 billion |

| Forecast CAGR (2025 to 2035) | 8.6% |

The blow-fill-seal equipment market is experiencing substantial growth. Increasing demand for sterile and contamination-free packaging, particularly in the pharmaceutical and biotechnology sectors, is driving adoption. Current market dynamics are influenced by stringent regulatory standards, rising preference for automation, and technological advancements that enhance production efficiency and reduce operational costs.

Manufacturers are focusing on optimizing equipment performance, improving energy efficiency, and expanding service capabilities to maintain competitive advantage. The future outlook is shaped by growing pharmaceutical production, expansion of biologics and vaccine manufacturing, and rising demand in emerging markets where healthcare infrastructure is improving.

Growth rationale is based on the increasing need for high-speed, precise, and reliable packaging solutions that ensure product safety and compliance Continued innovation, coupled with scalability in production capacity and versatility across container types, is expected to sustain market expansion and strengthen adoption across multiple industrial and pharmaceutical applications.

The up to 5,000 containers per hour segment has been leading the production capacity category. Its dominance is attributed to widespread adoption in small to mid-scale manufacturing facilities where flexibility and efficiency are critical. Equipment in this segment is designed to balance speed with precision, ensuring product sterility while maintaining operational reliability.

Demand has been sustained by pharmaceutical and biotechnology companies focusing on moderate-volume production, which allows for cost-effective scaling and customization. Manufacturers have implemented process optimization and automation technologies to enhance throughput and reduce downtime.

Regulatory compliance, ease of integration with existing production lines, and maintenance support have reinforced market preference Ongoing upgrades in machinery design and process monitoring are expected to maintain the segment’s leading share and enable consistent growth within the production capacity category.

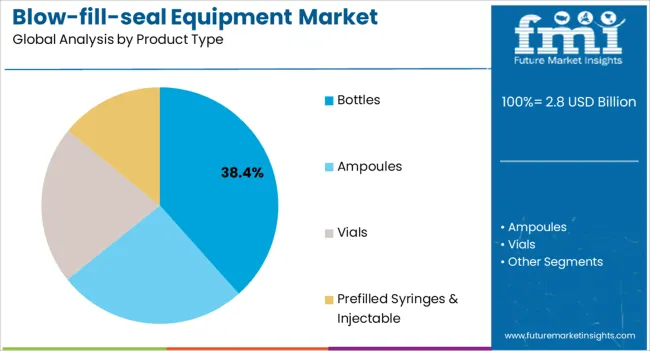

The bottles product type segment, representing 38.4% of the product category, has been leading due to its extensive application across liquid pharmaceuticals and sterile formulations. Adoption has been driven by versatility in container shapes and sizes, compatibility with automated filling systems, and compliance with strict regulatory standards.

Market preference has been strengthened by advancements in material handling, sealing technology, and quality assurance protocols that ensure product integrity. Demand has been stabilized by the expanding pharmaceutical sector and increasing requirements for sterile packaging solutions.

Manufacturers are investing in design enhancements to improve efficiency, reduce material waste, and accommodate higher production speeds These factors are expected to sustain the segment’s market share and reinforce its position as the preferred product type in the blow-fill-seal equipment market.

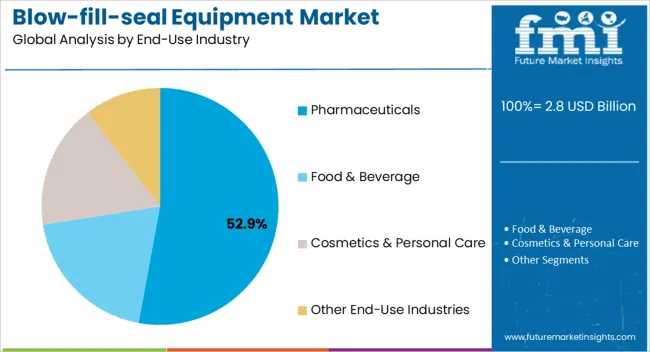

The pharmaceuticals end-use industry segment, holding 52.9% of the category, has emerged as the leading application due to the critical need for sterile packaging in drug manufacturing. Adoption has been facilitated by regulatory mandates, high production volumes, and the growing biologics and vaccine markets.

Equipment reliability, consistency in sealing, and compliance with international standards have reinforced preference within pharmaceutical production. Demand stability is being driven by increasing healthcare spending, expansion of pharmaceutical manufacturing facilities, and rising adoption of automated, high-precision packaging solutions.

Continuous innovation in blow-fill-seal technology, coupled with enhanced monitoring and quality assurance systems, is expected to maintain the segment’s leading share and support long-term growth in pharmaceutical applications.

| Particulars | Details |

|---|---|

| H1 2024 | 6.6% |

| H1 2025 Projected | 6.5% |

| H1 2025 Expected | 6.7% |

| BPS Change - H1, 2025 (O) - H1, 2025 (P) | (+) 20 ↑ |

| BPS Change - H1, 2025 (O) - H1, 2024 | (+) 10 ↑ |

The blow-fill-seal (BFS) product market surged by ten basis share points (BPS) in H1-2025 (O) against comparison with H1-2024, according to our analysis. Comparing the H1-2025 projected and H1-2025 outlook period, a rise in BPS change by 20 BPS has been noticed.

The key reason for this change in growth rate is due to high-speed blow-fill seal equipment and blow-fill seal for aseptic packaging without human interpretation.

The figures obtained by a survey of global blow-fill-seal equipment market demand during the historical period from 2020 to 2025 have shown a notable downturn. Worldwide sales of machines for blow-fill-seal technology surged at 4.4% CAGR during this period. By the end of 2025, the net worth of the market reached almost USD 2.1 billion.

| Global Blow Fill Seal Equipment Market Size in 2025 | USD 2.1 billion |

|---|---|

| Historical CAGR from 2020 to 2025 | 4.4% |

Following the outbreak of COVID-19, the demand for safe and contamination-free packaging increased exponentially, accelerating the demand for BFS equipment. With the rising demand for aseptic packaging in the pharmaceutical industry, sales of BFS equipment increased during the historical period.

The global blow-fill-seal equipment market is projected to witness robust growth, with sales increasing by 1.4x from 2025 to 2035. Emerging market trends in the blow-fill-seal packaging industry are projected to propel the overall market at a 3.3% CAGR through 2035.

In recent years, the growing production of pharmaceutical drugs and increasing transportation of vaccines has provided impetus to the higher adoption of blow-fill-seal (BFS) packaging machines.

So, with favorable government initiatives and the adoption of innovative pharmaceutical packaging, demand for BFS equipment is expected to gain traction over the forecast period.

Unit dose-packaging solutions, such as the growing demand for BFS syringes, are creating lucrative growth opportunities for BFS equipment manufacturers. Also, demand for innovative and safe packaging, especially following the rising sales of packaged food and beverages, has increased the demand for BFS equipment.

With the increasing need for aseptic packaging for chemicals and drugs, the pharmaceutical industry is expected to hold over 90% of overall sales in the market. Besides liquid-filled containers, BFS equipment is also used to package ointments, gels, vaccines, and other drugs.

Additionally, universal acceptance of BFS equipment, especially by healthcare authorities such as the FDA, is boosting the demand for blow-fill-seal equipment in the pharmaceutical industry.

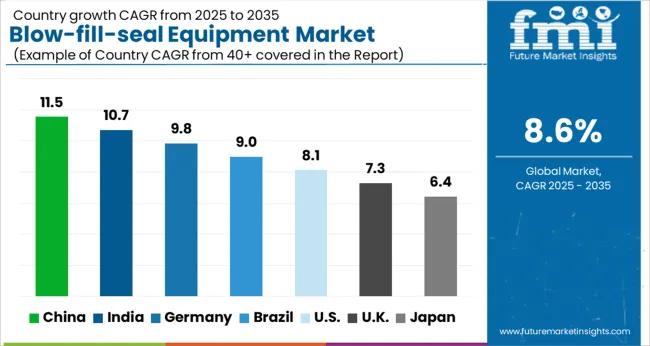

China is considered to be one of the largest pharmaceutical industries across the globe. According to the US Food and Drug Administration (FDA), China maintains around 13% of all regulated drugs and active pharmaceutical ingredients facilities across the globe.

Over the next ten years, the China form-fill-seal machine market is forecasted to experience a CAGR of 5.1%. Favorable government policies and increasing demand for safe and innovative packaging are expected to make China the most lucrative market in East Asia.

The United Kingdom is predicted to hold lucrative opportunities for market players. The market is expected to grow at a CAGR of 3.5% through 2035.

With the increasing development and adoption of liquid drugs, the need for safe and aseptic packaging could surge the United Kingdom's blow-fill-seal equipment market share. Hence, key players in Europe are eyeing the United Kingdom market to increase their revenues against the backdrop of increasing pharmaceutical drug production.

Over the coming years, India is expected to be the most lucrative market in East Asia for blow-fill-seal equipment. The market is expected to record a CAGR of 5.7%, attributable to the growing development of the packaging industry.

Additionally, increasing consumption of soft drinks and milk products across the country is also propelling growth in the market. However, high costs and complex operating standards might impede blow-fill-seal (BFS) packaging equipment sales in India.

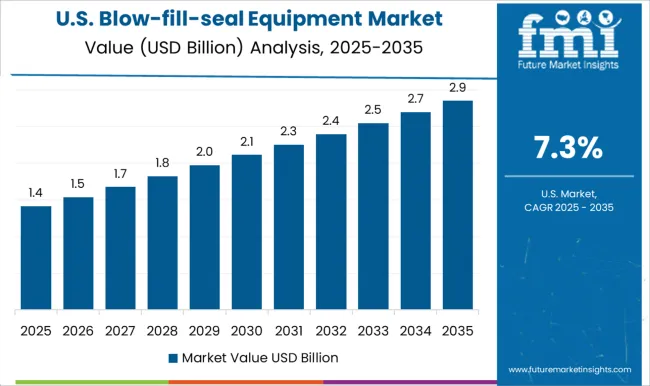

Demand for blow-fill-seal equipment is high across several industries related to consumer goods in the United States and is anticipated to register a 2.3% CAGR through 2035.

The United States blow-fill-seal equipment market is expected to hold a sizable share of demand across North America. The strong presence of numerous leading companies and their higher investment in the growth of polymer-based prefilled syringes is expected to fuel market performance in the future.

On account of a huge industrial base, the market share of BFSI security devices is poised to advance at 1.5% CAGR from 2025 to 2035.

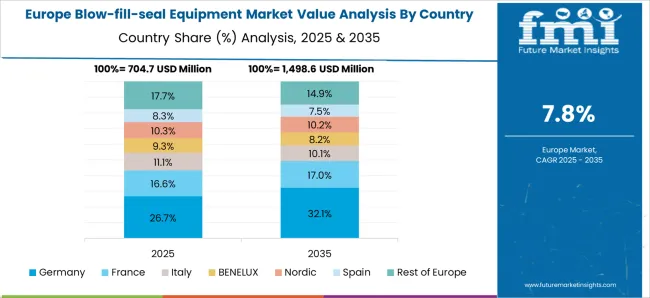

The requirement for aseptic and advanced packaging for liquid drugs and to improve product efficiency is increasing in Germany. Hence, key players in Germany are focusing on the expansion of their product portfolio and supply chain network to create remunerative revenues.

In terms of product type, the nestable blow-fill-seal equipment segment dominates the global market with a 49.5% revenue share in 2025. Increasing production of unit doses and the need for aseptic packaging are facilitating growth in this segment.

| Attributes | Details |

|---|---|

| Top Product Type | Nestable |

| Market Share in 2025 | 49.5% |

Blow-fill-seal (BFS) packaging equipment ensures that the product is not used more than once. Hence, healthcare companies are promoting the use of BFS technology and machines to curb the impact of communicable diseases. Despite these prospects, the improved sealing and leak prevention provided by HDPE is expected to drive growth in this segment.

| Attributes | Details |

|---|---|

| Top Material Type | HDPE |

| Market Share in 2025 | 67.1% |

A comparison and review analysis of the dynamics of the blow-fill-seal equipment market, the sealed wax packaging market, and the center sealed pouch packaging market have been provided in the section below.

The emerging trends in these three industries are principally subjected to an array of factors along with a few definite influences regarding the rising possibility of microbial contamination of the products that could restrain the growth of the blow-fill-seal equipment market.

Recent Developments in the Blow-fill-seal Equipment Market:

| Attribute | Details |

|---|---|

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | USD million or billion for Value |

| Key Regions Covered | North America; Latin America; Western Europe; Eastern Europe; Asia Pacific; Middle East & Africa (MEA) |

| Key Countries Covered | United States, Canada, Brazil, Mexico, Germany, United Kingdom, France, Italy, Spain, Nordic, Russia, Poland, China, India, Thailand, Indonesia, Australia and New Zealand, Japan, GCC countries, North Africa, South Africa, and others. |

| Key Market Segments Covered | By Production Capacity, By Product Type, By End-Use Industry, and By Region |

| Key Companies Profiled | Rommelag Kunststoff- Maschinen Vertriebsgesellschaft GmbH; Hunan CHINASUN Pharmaceutical Machinery Co. Ltd.; Bosch Packaging Technology GmbH; Weiler Engineering Inc.; Brevetti Angela S.R.L.; Marchesini Group S.p.A.; Serac Inc.; GEA Group; SIPA S.p.A.; Sidel S.A. |

| Report Coverage | Market Forecast, Company Share Analysis, Competition Intelligence, DROT Analysis, Market Dynamics and Challenges, and Strategic Growth Initiatives |

| Customization & Pricing | Available upon Request |

The global blow-fill-seal equipment market is estimated to be valued at USD 2.8 billion in 2025.

The market size for the blow-fill-seal equipment market is projected to reach USD 6.5 billion by 2035.

The blow-fill-seal equipment market is expected to grow at a 8.6% CAGR between 2025 and 2035.

The key product types in blow-fill-seal equipment market are up to 5,000 containers/hr., 5,000 to 10,000 containers/hr. and above 10,000 containers/hr..

In terms of product type, bottles segment to command 38.4% share in the blow-fill-seal equipment market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Equipment Management Software Market Size and Share Forecast Outlook 2025 to 2035

Equipment cases market Size and Share Forecast Outlook 2025 to 2035

Farm Equipment Market Forecast and Outlook 2025 to 2035

Golf Equipment Market Size and Share Forecast Outlook 2025 to 2035

Port Equipment Market Size and Share Forecast Outlook 2025 to 2035

Pouch Equipment Market Growth – Demand, Trends & Outlook 2025 to 2035

Garage Equipment Market Forecast and Outlook 2025 to 2035

Mining Equipment Industry Analysis in Latin America Size and Share Forecast Outlook 2025 to 2035

Subsea Equipment Market Size and Share Forecast Outlook 2025 to 2035

Pavers Equipment Market Size and Share Forecast Outlook 2025 to 2035

Tennis Equipment Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Galley Equipment Market Analysis and Forecast by Fit, Application, and Region through 2035

Sorting Equipment Market Size and Share Forecast Outlook 2025 to 2035

General Equipment Rental Services Market Size and Share Forecast Outlook 2025 to 2035

Bagging Equipment Market Size and Share Forecast Outlook 2025 to 2035

RF Test Equipment Market Size and Share Forecast Outlook 2025 to 2035

Medical Equipment Covers Market Size and Share Forecast Outlook 2025 to 2035

Telecom Equipment Market Size and Share Forecast Outlook 2025 to 2035

Welding Equipment And Consumables Market Size and Share Forecast Outlook 2025 to 2035

Hunting Equipment and Accessory Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA