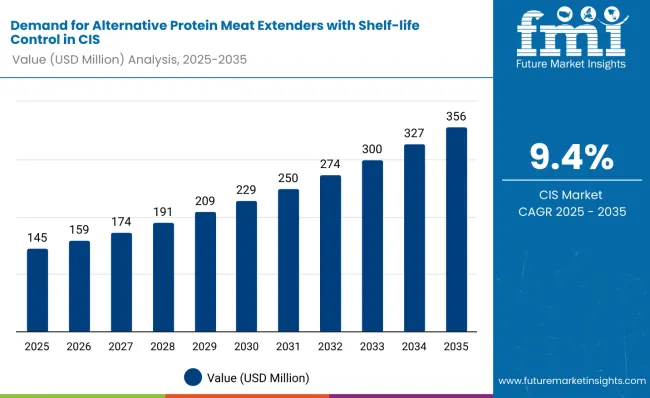

Demand for alternative protein meat extenders with shelf-life control in the Commonwealth of Independent States is estimated at USD 145 million in 2025, with projections indicating growth to USD 356 million by 2035, reflecting a CAGR of approximately 9.4% over the forecast period.

| Metric | Value |

|---|---|

| Industry Size (2025E) | USD 145 million |

| Industry Value (2035F) | USD 356 million |

| CAGR (2025 to 2035) | 9.4% |

This expansion reflects both increasing industrial adoption and enhanced per capita consumption across key CIS urban centers. The rise in demand is linked to cost optimization strategies in meat processing, growing awareness of protein diversification, and evolving food preservation technologies. By 2025, per capita consumption in leading CIS countries such as Russia, Kazakhstan, and Ukraine averages between 0.8 to 1.1 kilograms, with projections reaching 1.4 kilograms by 2035. Moscow leads among metropolitan areas, expected to generate USD 89 million in alternative protein meat extender sales by 2035, followed by Almaty (USD 31 million), Kyiv (USD 24 million), Minsk (USD 18 million), and Tashkent (USD 16 million).

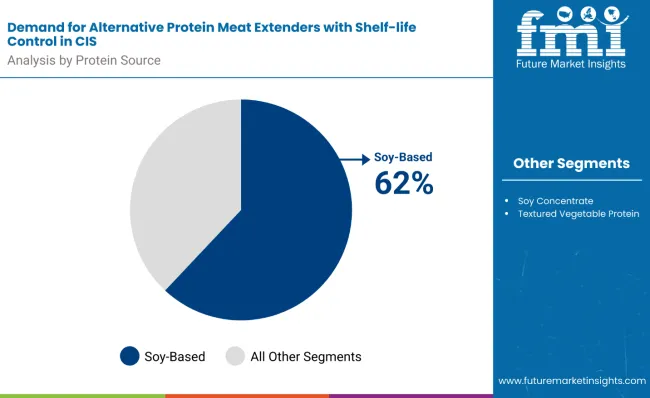

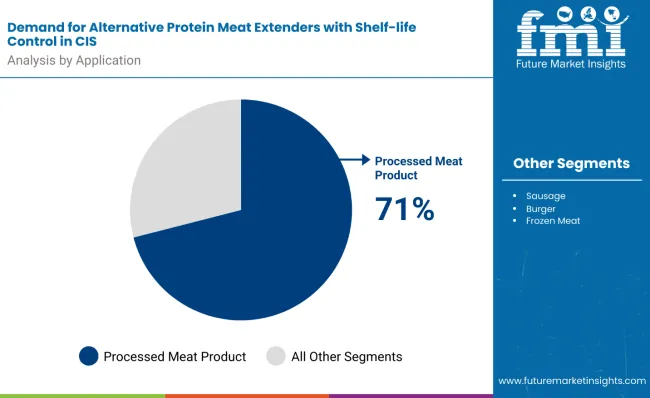

The largest contribution to demand continues to come from soy-based protein extenders, which are expected to account for 62% of total sales in 2025, owing to established supply chains, proven functionality, and cost effectiveness in industrial applications. By application segment, processed meat products represent the dominant usage category, responsible for 71% of all sales, while bakery and snack applications are expanding rapidly.

Consumer adoption is particularly concentrated among large-scale food manufacturers and cost-conscious processors, with production efficiency and protein standardization emerging as significant drivers of demand. While regulatory compliance remains a limiting factor, the average cost advantage over conventional protein sources has improved from 18% in 2020 to 24% in 2025. Continued improvements in preservation technology and local sourcing capabilities are expected to accelerate adoption across mid-scale processors. Regional disparities persist, but per capita demand in emerging Central Asian markets is narrowing the gap with traditionally strong Slavic processing hubs.

The alternative protein meat extenders segment in the CIS is classified across several categories. By protein source, the key types include soy-based concentrates, pea protein isolates, wheat gluten extenders, sunflower protein, and hybrid plant protein blends. By application, the segment spans processed meat products, bakery and confectionery, snack foods, ready-to-eat meals, and functional food formulations. By preservation technology, formulations include natural antioxidant systems, synthetic preservative blends, vacuum-sealed packaging solutions, modified atmosphere packaging, and freeze-dried protein matrices.

By end-user profile, the segment covers large-scale meat processors, regional food manufacturers, artisanal producers, export-oriented companies, and cost-optimization focused processors. By country, markets such as Russia, Kazakhstan, Ukraine, Belarus, and Uzbekistan are included, along with coverage across all 12 CIS member states. By city, key processing centers analyzed include Moscow, Almaty, Kyiv, Minsk, and Tashkent.

Soy-based protein extenders are projected to dominate sales in 2025, supported by established agricultural infrastructure, processing familiarity, and reliable functionality. Other protein sources such as pea, wheat, and emerging alternatives are growing steadily, each serving distinct processing requirements.

Alternative protein meat extenders in the CIS are utilized across diverse food applications. Processed meat products are expected to remain the primary application in 2025, followed by bakery products and emerging snack applications. Application strategies are evolving to match industrial processing capabilities, with growth coming from both traditional and innovative food categories.

Alternative protein meat extenders in the CIS utilize various preservation approaches, selected for regulatory compliance, cost effectiveness, and shelf-life extension capabilities. Natural antioxidant systems remain the most widely adopted technology, though synthetic alternatives and advanced packaging solutions are gaining momentum.

The alternative protein meat extenders category appeals to diverse industrial users across processing scales, cost structures, and quality requirements. While motivations vary from cost reduction to protein standardization to regulatory compliance, demand is concentrated among five key processor categories. Each group brings distinct purchasing behaviors, volume requirements, and technology expectations.

| Countris | CAGR (2025 to 2035) |

|---|---|

| Kazakhstan | 3.2% |

| Uzbekistan | 3.2% |

| Belarus | 2.8% |

| Ukraine | 2.8% |

| Russia | 2.4% |

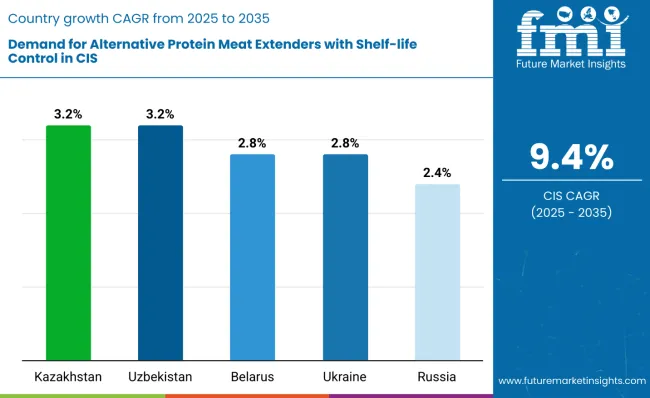

Alternative protein meat extender demand will not expand uniformly across every CIS member state. Rising industrial development and faster per capita adoption in Central Asian countries give Kazakhstan and Uzbekistan a measurable advantage, while mature Slavic processing hubs such as Russia expand more steadily from a higher base. The table below shows the compound annual growth rate (CAGR) each of the five largest countries is expected to record between 2025 and 2035.

Between 2025 and 2035, demand for alternative protein meat extenders is projected to expand across all major CIS countries, but the pace of growth will vary based on industrial modernization, processing infrastructure development, and baseline consumption levels. Among the top five countries analyzed, Kazakhstan and Uzbekistan are expected to register the fastest compound annual growth rate (CAGR) of 3.2%, outpacing more established processing economies.

This acceleration is underpinned by several factors: significant food industry investment, growing export-oriented meat processing, and increasing availability of locally-sourced protein ingredients across domestic suppliers and agricultural cooperatives. In both countries, per capita consumption is projected to rise from 0.9 kg in 2025 to 1.3 kg by 2035, closing the gap with higher-consumption countries such as Russia and Ukraine. Processing infrastructure is also expanding rapidly in these regions, with new protein extraction facilities and preservation technology gaining adoption in regional food hubs and industrial zones.

Belarus and Ukraine are each forecast to grow at a CAGR of 2.8% over the same period. Both countries already maintain established food processing ecosystems, with widespread adoption of soy-based and wheat protein extenders in meat manufacturing, bakery operations, and specialty food production. In Belarus, growth is supported by state-sponsored food security initiatives, technology modernization programs, and increasing integration with European supply chains. Ukraine reflects similar dynamics, particularly among processors seeking cost optimization and companies rebuilding production capacity. In both countries, per capita consumption is projected to increase from 1.0 kg in 2025 to 1.4 kg by 2035, reflecting continued industrialization of food processing operations.

Russia, while maintaining the highest overall consumption in absolute terms, is expected to grow at a CAGR of 2.4%, slightly below its regional counterparts. The country already exhibits higher-than-average per capita usage (1.1 kg in 2025), extensive processing infrastructure, and established supplier networks. Growth will likely come from production optimization, new preservation technologies, and specialty protein applications rather than basic market expansion.

Collectively, these five countries represent the core of industrial demand for alternative protein meat extenders in the CIS, but their individual growth trajectories highlight the importance of country-specific approaches in product development, pricing strategies, and distribution partnerships.

The competitive environment is characterized by a mix of established agricultural processors and specialized protein ingredient companies. Supply chain reliability rather than product innovation remains the decisive success factor: the five largest suppliers collectively serve more than 2,500 food processing facilities across the CIS and account for a majority of soy and pea protein ingredient sourcing in the region.

Solnechnye Produkty is the most established participant. Based in Russia, the company offers more than 180 plant protein ingredients, all sourced from domestic agricultural operations. Its core range of soy concentrates and wheat proteins provides deep penetration in meat processing facilities while maintaining full regional coverage through distributors in Kazakhstan, Belarus, and Ukraine.

Protein Technologies Kazakhstan, established in 2019, leverages Central Asia's growing agricultural capacity to supply pea protein isolates and sunflower protein concentrates to regional meat processors and export companies. Recent infrastructure investments have allowed the company to introduce custom preservation systems priced competitively with imported alternatives, reinforcing its role as a key regional supplier for CIS protein ingredient demand.

, owned by Belarusian Agricultural Consortium, benefits from government support within a USD 2.8 billion food processing sector and from integration with state-owned meat processing facilities. Recent product launches under the NaturProtein brand extend beyond basic extenders into specialized preservation systems and functional protein ingredients targeting premium processing applications.

The next tier comprises private companies and agricultural cooperatives. Ros Agro PLC (Rusagro) focuses on organic-certified protein extenders and natural preservation systems; recent financial reports showed quarterly revenue of USD 12 million, indicating significant but still specialized market position. Private-label programs at major food distributors and agricultural cooperatives are expanding protein ingredient availability at price points 8-12% below branded equivalents, creating pressure on smaller suppliers while supporting adoption among cost-sensitive processors. Consolidation is therefore likely to continue as production scale and regional distribution become critical for maintaining processing facility relationships and consistent supply availability in this developing category.

| Attribute | Details |

|---|---|

| Study Coverage | CIS demand and consumption of alternative protein meat extenders from 2020 to 2035 |

| Base Year | 2025 |

| Historical Data | 2020 |

| Forecast Period | 2025-2035 |

| Units of Measurement | USD (sales), Metric Tonnes (volume), Kilograms per capita (consumption) |

| Geography Covered | All 12 CIS member states; country-level and city-level granularity |

| Top Countries Analyzed | Russia, Kazakhstan, Ukraine, Belarus, Uzbekistan, 12+ |

| Top Cities Analyzed | Moscow, Almaty, Kyiv, Minsk, Tashkent and 25+ |

| By Protein Source | Soy-based, Pea protein, Wheat gluten, Sunflower protein, Hybrid blends |

| By Application | Processed meat products, Bakery/confectionery, Snack foods, Ready-to-eat meals, Functional foods |

| By Preservation Technology | Natural antioxidants, Synthetic preservatives, Vacuum packaging, Modified atmosphere, Freeze-dried systems |

| By End-user Profile | Large-scale processors, Regional manufacturers, Artisanal producers, Export companies, Cost-focused processors |

| Metrics Provided | Sales (USD), Volume (MT), Per capita consumption (kg), CAGR (2025-2035), Share by segment |

| Price Analysis | Average unit prices by protein source and preservation technology |

| Competitive Landscape | Company profiles, supply chain strategies, regional vs. international presence |

| Forecast Drivers | Per capita demand trends, processing infrastructure, cost optimization, industrial development |

By 2035, total CIS sales of alternative protein meat extenders with shelf-life control are projected to reach USD 356 million, up from USD 145 million in 2025, reflecting a CAGR of approximately 9.4%.

Soy-based extenders hold the leading share, accounting for approximately 62% of total sales in 2025, followed by pea protein isolates and wheat gluten extenders.

Kazakhstan and Uzbekistan lead in projected growth, each registering a CAGR of 3.2% between 2025 and 2035, due to industrial development and processing infrastructure expansion.

Processed meat products are the dominant application (71% share in 2025), but bakery and snack food applications are growing at double-digit rates, especially in urban processing centers.

Major players include Solnechnye Produkty, Ros Agro PLC (Rusagro) with growing competition from regional agricultural cooperatives and specialized ingredient suppliers.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Meat Alternative Market Forecast and Outlook 2025 to 2035

Alternative Protein Production Equipment Market Size and Share Forecast Outlook 2025 to 2035

Alternative Proteins for Pets Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Alternative Protein Market Insights - Sustainable Food Trends 2025 to 2035

Soy-Based Meat Alternative Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Animal Feed Alternative Protein Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

A detailed global analysis of Brand Share Analysis for Animal Feed Alternative Protein Industry

High-Protein Plant-Based Cheese Alternatives in the EU Analysis Size and Share Forecast Outlook 2025 to 2035

UK Animal Feed Alternative Protein Market Growth – Trends, Demand & Innovations 2025–2035

Pea Protein Demand in Dairy Alternatives Analysis - Size Share and Forecast outlook 2025 to 2035

ASEAN Animal Feed Alternative Protein Market Insights – Demand, Size & Industry Trends 2025–2035

Europe Animal Feed Alternative Protein Market Insights – Demand, Trends & Forecast 2025–2035

Pea Protein in Plant-Based Meat Analysis - Size Share and Forecast outlook 2025 to 2035

Australia Animal Feed Alternative Protein Market Report – Size, Share & Innovations 2025-2035

Latin America Animal Feed Alternative Protein Market Analysis – Growth & Forecast 2025–2035

Meat Snacks Market Size and Share Forecast Outlook 2025 to 2035

Protein-Coating Line Market Forecast Outlook 2025 to 2035

Meat, Poultry, and Seafood Packaging Market Size and Share Forecast Outlook 2025 to 2035

Alternative Lending Platform Market Size and Share Forecast Outlook 2025 to 2035

Protein Labelling Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA