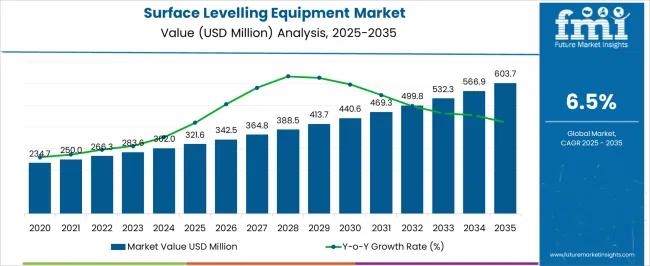

The Surface Levelling Equipment Market is estimated to be valued at USD 321.6 million in 2025 and is projected to reach USD 603.7 million by 2035, registering a compound annual growth rate (CAGR) of 6.5% over the forecast period. The initial growth phase from 2020 to 2025 sees the market rise from USD 234.7 million to USD 302 million, driven by rising demand from industries such as automotive, aerospace, and metal fabrication, where precise surface finishing is critical. This period is marked by increasing adoption of advanced levelling technologies that enhance product quality, reduce manufacturing defects, and improve operational efficiency.

Technological advancements in automation, sensor integration, and process control further support market expansion. Between 2026 and 2030, the market advances from USD 321.6 million to USD 388.5 million, fueled by continued investments in manufacturing modernization and growing emphasis on product durability and performance. Emerging economies contribute to market growth as industrial sectors expand and infrastructure projects increase.

The latter half of the forecast period, from 2031 to 2035, experiences accelerated growth, with the market climbing from USD 413.7 million to USD 603.7 million. This surge is propelled by advancements in levelling equipment designed for high-precision applications, integration with Industry 4.0 systems, and increasing demand for lightweight, high-strength materials across various sectors. Overall, the surface levelling equipment market is poised for robust and sustained growth through 2035, driven by technological innovation, expanding end-use industries, and global industrialization trends.

| Metric | Value |

|---|---|

| Surface Levelling Equipment Market Estimated Value in (2025 E) | USD 321.6 million |

| Surface Levelling Equipment Market Forecast Value in (2035 F) | USD 603.7 million |

| Forecast CAGR (2025 to 2035) | 6.5% |

The surface levelling equipment market is witnessing steady expansion, supported by increasing demand for precise, time-efficient concrete finishing in industrial, commercial, and residential construction. Accelerated urban infrastructure development, labor cost pressures, and a push for high-performance flooring have led to increased mechanization on construction sites.

Improved safety regulations and the emphasis on surface uniformity, durability, and strength in commercial floors are driving the adoption of advanced levelling equipment. Contractors are prioritizing equipment that reduces manual intervention and ensures consistent results with minimal downtime.

Additionally, innovations in electric-powered and ride-on systems are expanding applicability across different site conditions. As construction timelines compress and skilled labor availability tightens, investment in durable, efficient, and operator-friendly levelling solutions is expected to rise across global markets.

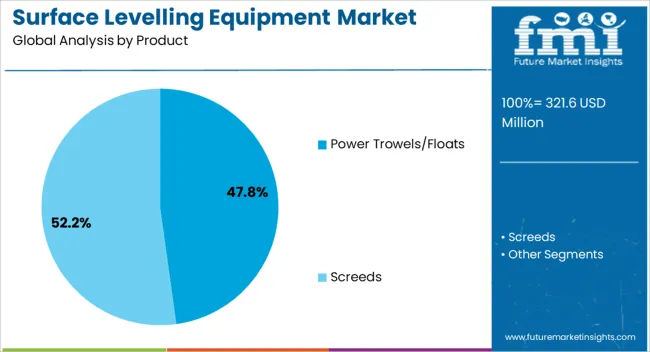

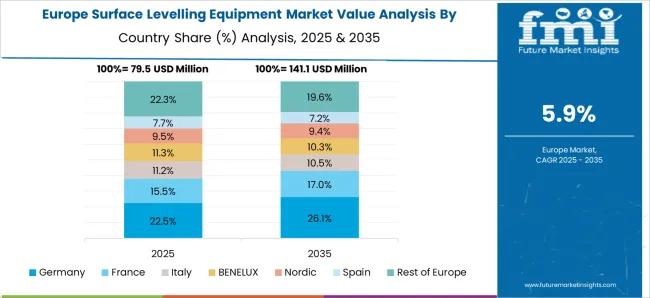

The surface levelling equipment market is segmented by product and geographic regions. By product, the surface levelling equipment market is divided into Power Trowels/Floats and Screeds. Regionally, the surface levelling equipment industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Power trowels/floats are projected to hold a leading 47.80% share of the surface levelling equipment market revenue in 2025. This leadership is being driven by their broad application in slab finishing, versatility across site sizes, and ability to deliver smooth, flat surfaces in less time.

These machines have gained preference due to their adaptability in both ride-on and walk-behind configurations, enabling their use in everything from small warehouse jobs to large industrial floors. The segment's growth has also been supported by innovations in blade technology, engine efficiency, and ergonomics, which enhance operator comfort and reduce fatigue during extended use.

Rising demand for quality assurance in concrete surface work, especially in commercial real estate and logistics infrastructure, is reinforcing the uptake of power trowels/floats. Their proven reliability and cost-effectiveness continue to position them as essential tools in modern construction workflows.

The surface levelling equipment market is driven by growth in infrastructure projects, automation trends, and a focus on energy efficiency. Technological advancements further enhance the precision and speed of these systems.

The demand for surface levelling equipment is largely driven by the expansion of infrastructure projects, including roads, highways, and residential developments. Governments and private sectors are investing heavily in the construction of durable and well-maintained infrastructure, which boosts the need for precise levelling. Surface levelling equipment ensures that the surfaces of roads, pavements, and industrial floors meet the required specifications for safety and functionality. This demand is expected to increase with large-scale urban redevelopment and the construction of commercial complexes globally. The growth of these sectors presents a significant opportunity for manufacturers to meet evolving project needs and customer expectations.

The market for surface levelling equipment is witnessing a shift towards automated systems designed to enhance operational efficiency. Automated machinery offers advantages such as reduced labor costs, enhanced precision, and faster project completion times. This trend is gaining traction across industries that require high surface accuracy, such as road and pavement construction. The increasing demand for quicker construction timelines has led to the adoption of more efficient, automated surface levelling machines. These machines incorporate sensors and digital controls to ensure the precise leveling of surfaces, contributing to faster, safer, and more cost-effective construction projects.

With the growing emphasis on reducing operational costs and environmental impact, energy-efficient surface levelling equipment has gained prominence in the market. Manufacturers are focusing on producing equipment that minimizes fuel consumption and operational costs, ensuring better performance while reducing emissions. This shift is becoming particularly important in regions with strict regulations around emissions and environmental standards. The development of electric-powered surface levelling machines is catering to a more eco-conscious market. These machines not only support compliance with environmental policies but also offer lower maintenance costs and greater operational efficiency, making them a preferred choice for contractors.

Manufacturers are focusing on designing user-friendly surface levelling machines that require less training and manual input from operators. These machines often include intuitive interfaces, automated controls, and enhanced maneuverability, which simplifies operation on complex construction sites. Such innovations are catering to the demand for more cost-effective and efficient equipment that can reduce operational costs while maintaining high standards of quality.

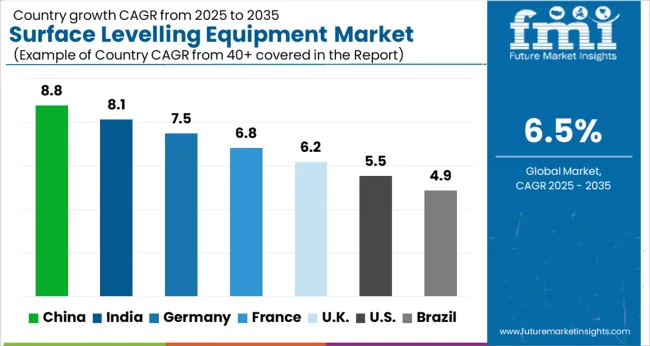

The surface levelling equipment market is projected to grow globally at a CAGR of 6.5% from 2025 to 2035, driven by increasing demand for infrastructure development, industrial expansion, and technological advancements in levelling and surface treatment processes. China leads with a CAGR of 8.8%, supported by rapid urbanization, large-scale construction projects, and growing demand from the manufacturing and infrastructure sectors. India follows at 8.1%, fueled by the country’s ongoing infrastructure boom, urbanization, and increasing demand for surface levelling equipment in construction, roads, and commercial projects.

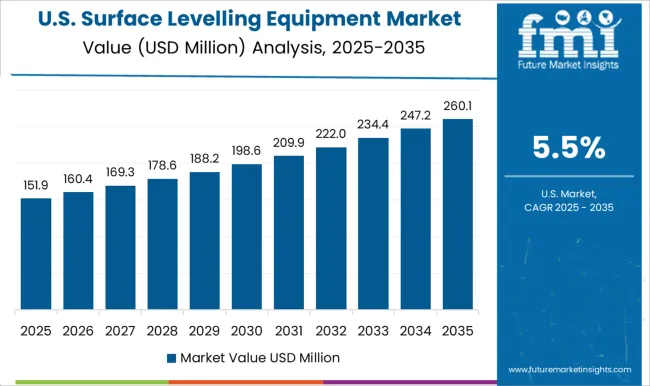

Germany grows at 7.5%, with strong demand driven by industrial applications, including precision levelling in manufacturing and construction. The United Kingdom achieves a CAGR of 6.2%, benefiting from steady demand in commercial, residential, and road construction sectors, while the United States records a CAGR of 5.5%, supported by growing industrial and construction activities across various sectors. This growth trajectory highlights the increasing importance of surface levelling equipment in infrastructure, manufacturing, and construction projects worldwide, with a focus on precision and efficiency in surface preparation.

The UK’s surface levelling equipment market grew at a CAGR of 4.7% from 2020 to 2024 and is expected to rise to 6.2% during 2025-2035. The growth during 2020-2024 was driven by steady demand from the construction and infrastructure sectors, with a focus on road construction and urban development. However, as the construction and manufacturing sectors recover and grow in the coming decade, the market is expected to see an uptick in growth due to rising demand for efficient and precise levelling equipment for complex infrastructure projects. The push for sustainability, energy efficiency, and modernizing infrastructure will further drive the growth of surface levelling equipment in the UK. Moreover, technological advancements, such as automation and smart levelling systems, will also play a key role in enhancing the market's growth.

China’s surface levelling equipment market is projected to grow at a CAGR of 8.8% during 2025-2035, outpacing the global CAGR of 6.5%. The market grew at a CAGR of 7.2% during 2020-2024, driven by the country’s rapid urbanization, large-scale infrastructure projects, and increasing demand for high-performance levelling equipment in manufacturing, road construction, and commercial projects. The growth rate will accelerate in the coming decade due to ongoing investments in infrastructure and a surge in demand for advanced surface levelling solutions that cater to both residential and industrial applications. The country’s emphasis on precision and automation in construction will play a significant role in driving the market.

India’s surface levelling equipment market is expected to grow at a CAGR of 8.1% from 2025 to 2035, higher than the global average of 6.5%. The market grew at a CAGR of 7.3% from 2020 to 2024, supported by the country’s rapid infrastructure expansion and growing construction activities, particularly in urban areas. The accelerated growth is expected due to the increasing number of residential, commercial, and industrial construction projects and the need for efficient, precise levelling equipment in these developments. Additionally, the government’s focus on road construction and infrastructure improvement will further increase the demand for surface levelling machinery.

Germany’s surface levelling equipment market is projected to grow at a CAGR of 7.5% during 2025-2035. The market grew at a CAGR of 6.4% during 2020-2024, driven by steady demand from both residential and commercial construction, as well as industrial applications. The expected rise in the coming decade will be driven by Germany’s strong construction sector, technological advancements, and a focus on precision in surface levelling for manufacturing and infrastructure projects. Additionally, the growing trend toward automation in construction and road building, alongside increasing regulations for efficiency and environmental sustainability, will contribute to higher market growth.

The USA surface levelling equipment market is projected to grow at a CAGR of 5.5% during 2025-2035. The market grew at a CAGR of 4.2% from 2020 to 2024, supported by steady demand from the construction, industrial, and manufacturing sectors. The market is expected to accelerate as the demand for efficient, high-performance levelling equipment in large-scale infrastructure and commercial projects increases. The USA focus on automation and sustainable construction practices, along with government infrastructure development initiatives, will contribute to higher demand for advanced surface levelling equipment in the coming decade.

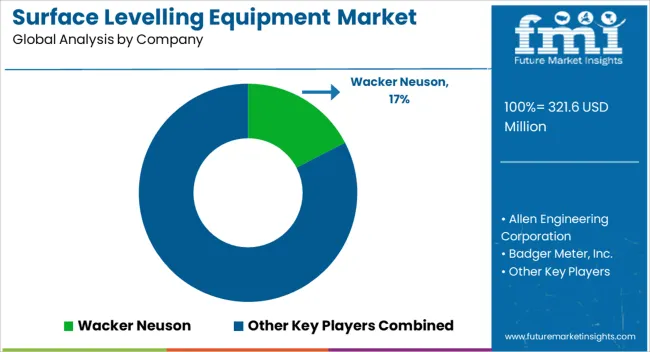

The surface levelling equipment market is highly competitive, with key players such as Wacker Neuson, Allen Engineering Corporation, Badger Meter, Inc., Bartell Global Inc., and Chicago Pneumatic contributing to the industry’s growth and innovation. Wacker Neuson is recognized for its robust and versatile range of surface levelling equipment, catering to both small-scale and large-scale construction projects with a focus on high-performance and reliability.

Allen Engineering Corporation leads the market with advanced concrete and surface levelling solutions, known for their precision and durability. Badger Meter, Inc. offers cutting-edge measurement and control solutions, enhancing surface levelling processes in various applications. Bartell Global Inc. is a significant player, offering a diverse portfolio of equipment designed to meet varying demands in construction.

Chicago Pneumatic is known for its heavy-duty machinery, providing efficient and high-quality levelling equipment suited for demanding industrial tasks. Other players, such as Husqvarna AB, Lievers Holland, Lindley, Inc., MBW Inc., and Multiquip Inc., contribute significantly to the competitive landscape with their specialized equipment and unique value propositions.

Husqvarna AB is a leading player, offering innovative machinery with enhanced operational efficiency. Lievers Holland specializes in creating precision levelling systems for specific applications, while Lindley, Inc. focuses on creating durable, user-friendly equipment. MBW Inc. and Multiquip Inc. both emphasize heavy-duty solutions designed for large-scale construction projects, reinforcing their strong presence in the market.

Caterpillar and Volvo are integrating laser-guided and automated systems for more accurate surface finishes in construction and paving. Allen Engineering and GOMACO are innovating with ride-on levelers and concrete finishers to improve efficiency in large-scale infrastructure projects. Additionally, Case Construction focuses on energy-efficient and operator-friendly designs for smoother surfaces. Companies are increasingly adopting eco-friendly technologies to meet sustainable construction goals, driving demand across industries like construction, automotive, and metal processing.

| Item | Value |

|---|---|

| Quantitative Units | USD 321.6 Million |

| Product | Power Trowels/Floats and Screeds |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Wacker Neuson, Allen Engineering Corporation, Badger Meter, Inc., Bartell Global Inc., Chicago Pneumatic, Husqvarna AB, Lievers Holland, Lindley, Inc., MBW Inc., and Multiquip Inc. |

| Additional Attributes | Dollar sales by region, market share of key players, demand trends in construction and infrastructure sectors, growth drivers, technological advancements, and competitive strategies. They would also focus on regional growth opportunities, regulatory impacts, and cost-effective innovations. |

The global surface levelling equipment market is estimated to be valued at USD 321.6 million in 2025.

The market size for the surface levelling equipment market is projected to reach USD 603.7 million by 2035.

The surface levelling equipment market is expected to grow at a 6.5% CAGR between 2025 and 2035.

The key product types in surface levelling equipment market are power trowels/floats, _walk-behind power floats, _ride-on power floats, screeds, _wet screeds and _truss screeds.

In terms of , segment to command 0.0% share in the surface levelling equipment market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Surface Mining Equipment Market Size and Share Forecast Outlook 2025 to 2035

Surface Measurement Equipment And Tools Market

Surface Water Sports Equipment Market Size and Share Forecast Outlook 2025 to 2035

Water Surface Conditioning Equipment Market Size and Share Forecast Outlook 2025 to 2035

Surface Contact Wire Rope Market Size and Share Forecast Outlook 2025 to 2035

Surface Protection Service Market Size and Share Forecast Outlook 2025 to 2035

Surface Protection Film Market Forecast and Outlook 2025 to 2035

Surface printed Film Market Size and Share Forecast Outlook 2025 to 2035

Surface Treatment Chemicals Market Size and Share Forecast Outlook 2025 to 2035

Surface Mounting Distribution Panel Market Size and Share Forecast Outlook 2025 to 2035

Surface Mounted Medium Voltage Distribution Panel Market Size and Share Forecast Outlook 2025 to 2035

Surface Radars Market Size and Share Forecast Outlook 2025 to 2035

Surface Mining Market Size and Share Forecast Outlook 2025 to 2035

Surface Mount Technology Market Size and Share Forecast Outlook 2025 to 2035

Equipment Management Software Market Size and Share Forecast Outlook 2025 to 2035

Equipment cases market Size and Share Forecast Outlook 2025 to 2035

Surface Disinfectant Chemicals Market Growth & Demand 2025 to 2035

Surface Disinfectant Market is segmented by product type, form and end user from 2025 to 2035

Surface Disinfectant Products Market Growth - Trends and Forecast 2025 to 2035

Competitive Overview of Surface Printed Film Companies

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA