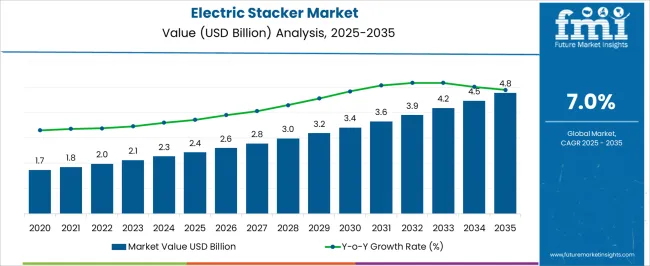

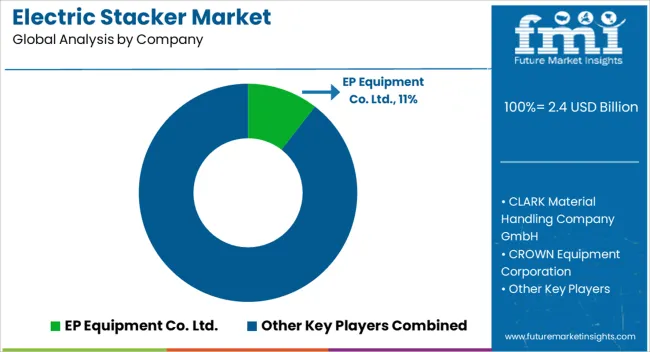

The Electric Stacker Market is estimated to be valued at USD 2.4 billion in 2025 and is projected to reach USD 4.8 billion by 2035, registering a compound annual growth rate (CAGR) of 7.0% over the forecast period.

| Metric | Value |

|---|---|

| Electric Stacker Market Estimated Value in (2025 E) | USD 2.4 billion |

| Electric Stacker Market Forecast Value in (2035 F) | USD 4.8 billion |

| Forecast CAGR (2025 to 2035) | 7.0% |

The electric stacker market is showing consistent growth, supported by rising automation in material handling and increasing adoption of energy-efficient equipment across logistics and manufacturing industries. Industry announcements and trade publications have emphasized the role of electric stackers in improving operational efficiency, reducing labor costs, and aligning with sustainability objectives by lowering emissions compared to internal combustion counterparts.

Expanding e-commerce, warehousing, and third-party logistics networks have further accelerated demand for stackers capable of handling frequent, repetitive lifting and transportation tasks. Manufacturers have introduced advanced models with improved battery life, ergonomic controls, and compact designs to meet the needs of both small businesses and large-scale facilities.

Additionally, workplace safety regulations and the push toward electrification in industrial equipment have reinforced market adoption. Looking ahead, growth is expected to continue through the integration of smart technologies, such as IoT-enabled monitoring and automated fleet management systems, positioning electric stackers as an essential component of modern material handling solutions.

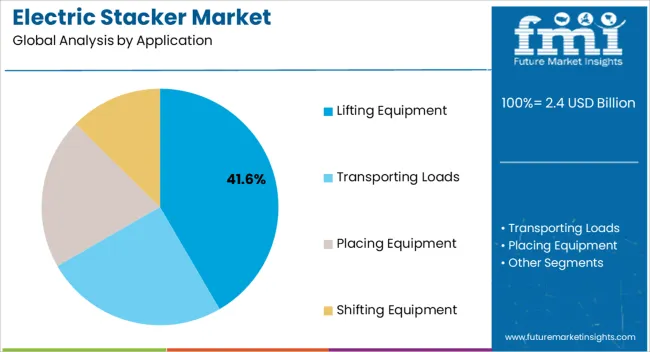

The Lifting Equipment segment is projected to account for 41.60% of the electric stacker market revenue in 2025, establishing itself as the primary application. Growth has been driven by the segment’s ability to improve efficiency in loading, unloading, and stacking operations across warehousing and industrial facilities.

Electric stackers used in lifting applications have been favored for their adaptability in confined spaces, precise control, and reduced reliance on manual labor. Workplace safety guidelines and ergonomic considerations have further encouraged businesses to replace manual lifting processes with electric-powered alternatives.

With e-commerce fulfillment centers and large-scale storage hubs increasing in number, lifting equipment has become a critical tool in handling diverse product categories. Continuous innovation in compact and high-performance models has ensured their suitability across both small and large operations, sustaining the segment’s market leadership.

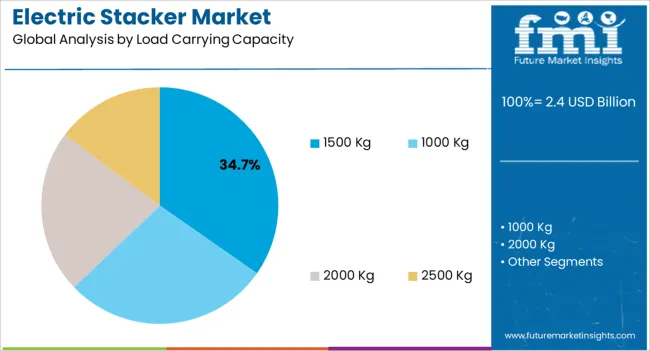

The 1500 Kg segment is anticipated to hold 34.70% of the electric stacker market revenue in 2025, maintaining its dominance due to its balance of versatility and cost-effectiveness. Equipment with this load capacity has been preferred in logistics, retail, and light manufacturing sectors where medium-weight loads are frequently managed.

Industry reports have noted that the 1500 Kg capacity strikes an optimal balance between power efficiency and operational flexibility, making it suitable for a wide range of warehouse configurations. Manufacturers have standardized product offerings around this load class, ensuring wide availability and competitive pricing.

Additionally, businesses have adopted 1500 Kg stackers as a cost-efficient alternative to larger forklifts, particularly in environments with space constraints. With ongoing demand for mid-range lifting solutions in fast-growing sectors such as retail distribution and consumer goods, the 1500 Kg capacity segment is expected to remain central to the market.

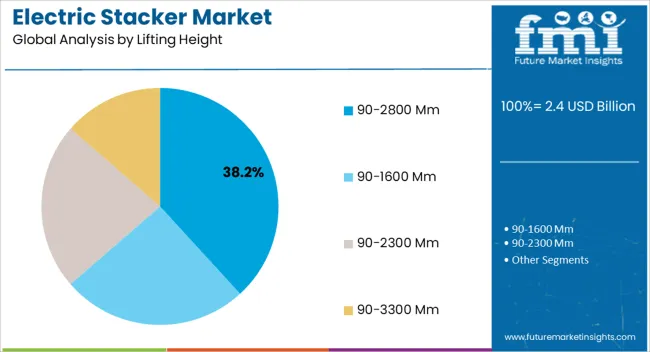

The 90–2800 Mm segment is projected to contribute 38.20% of the electric stacker market revenue in 2025, leading the lifting height category. Its prominence has been shaped by the ability to handle diverse stacking tasks across varying warehouse layouts and storage needs.

This range has been valued by operators for offering sufficient flexibility to manage both low-level pallet movement and medium-height racking operations without the need for specialized equipment. Trade publications have highlighted that the 90–2800 Mm range is widely adopted in small to mid-sized facilities where ceiling height constraints and storage optimization are key considerations.

Equipment manufacturers have developed robust models within this height category, integrating advanced safety systems and user-friendly controls to enhance productivity. The growing need for efficient vertical storage utilization, coupled with the expansion of e-commerce warehouses, has reinforced the dominance of this lifting height segment. As businesses continue to optimize warehouse space, demand for electric stackers within this height range is expected to remain strong.

The comparison between the historical and prospective trajectories of the electric stacker market highlights a remarkable transition. In 2025, the market registered a total of USD 1,987.7 million in value, demonstrating a CAGR of 5.3%. Between 2020 and 2025, the market experienced a substantial surge, primarily propelled by the escalating demand for streamlined material handling solutions across diverse sectors. This surge stemmed from the inherent advantages offered by electric stackers, including cost efficiency, diminished emissions, and enhanced operational agility.

During the forecast period, the market is poised for further expansion, revealing an even more pronounced transformation. The driving forces behind this impending proliferation encompass an augmented focus on warehouse optimization, the integration of automation into material handling workflows, and the continual progression of battery technologies. These factors collectively lay the groundwork for a substantial amplification of the market during the forecast period.

Compact material handling equipment and its adoption have gained much attention in recent years owing to their movability, easier maintenance, and equivalence to heavy machinery. Additionally, electric stackers do not require certified operators and are significantly easier to operate, unlike heavy types of machinery.

Powered industrial trucks, such as electric stackers, effectively minimize manual labor by facilitating the efficient transfer of diverse components from warehouses to production lines. This operational efficiency not only streamlines processes but also contributes to reduced emissions of pollutants. Additionally, the notable benefit of not needing to store fuel on-site for stacker operation is predicted to drive the market expansion further.

The components of electric stackers offer optimal productivity to all its applications. Moreover, various end user industries are adopting battery-operated stackers, owing to their ability to horizontal transport as well as handle double pallets. This presents lots of opportunities for the electric stacker market going forward.

The rising trend toward automation and technological advancements in electric stackers, such as the integration of Internet of Things and remote monitoring capabilities, has further augmented their market presence. The cost-effective and eco-friendly nature of electric stackers compared to traditional fuel-powered alternatives has also played a significant role in their proliferation across various industries.

The demand for electric stackers from the e-commerce sector is likely to rise as online retailers deploy high-quality stackers in distribution facilities to streamline material handling operations. Logistic operations are prominently integrating electric stackers as an essential cost-saving measure. It reduces dependence on gasoline and reaping environmental advantages. Additionally, the reliability and predictability of maintenance and replacement costs for lead-acid batteries are anticipated to propel the widespread adoption of electric stackers across diverse end user segments.

The market is poised to experience growth, driven by increasing environmental protection awareness and the progressing economy. As businesses prioritize sustainable practices, the demand for eco-friendly material handling solutions like electric stackers is anticipated to rise.

Several factors adversely influence the global electric stacker market's growth. New electric stables with more capacity and unclear information about their features might slow down market growth. Additionally, the cost of battery-operated and fuel-cell stackers could limit their adoption due to affordability concerns.

On the positive side, strict regulations focused on sustainability and emissions are driving companies to opt for eco-friendly solutions like electric stackers. This is boosting demand for these machines as businesses strive to meet environmental standards.

Several companies are concentrating on the advancement of stackers with features such as enhanced durability, robust construction, and smooth functioning. This might help drive the electric stacker market.

In short, while challenges like new stables and costs could slow the market growth, regulations, technology improvements, and better features are driving its evolution.

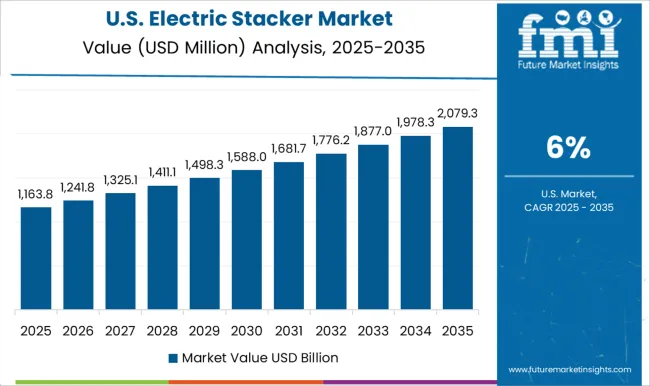

North America commanded a substantial 25.6% share of the electric stacker market in 2025. This dominance can be attributed to the escalating demand for more convenient lifting techniques and the manufacturing of diverse goods. These are key factors anticipated to fuel the market's expansion in this geographical area.

| Country | United States |

|---|---|

| 2025 Value Share in Global Market | 17.6% |

The presence of leading participants throughout the United States territory has propelled remarkable sales volume growth in this sector. These influential players have embraced contemporary and innovative electric stackers, departing from traditional material handling stackers. In the United States, the electric stacker sector has not only seen an increase in demand for traditional warehouse applications but has also found a unique niche in the agricultural industry. Electric stackers are being utilized on farms and agricultural facilities for tasks like loading and unloading produce. This showcases their versatility beyond conventional material handling.

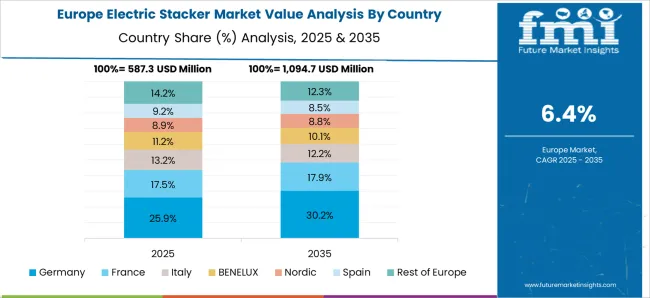

Europe electric stacker market is on the rise, having captured a substantial 23.2% share of global revenue in 2025, signifying a positive trend in the adoption of these machines within the region. The factors driving this growth are multifaceted. European industries strongly emphasize on improving efficiency and optimizing their material handling processes, leading to a heightened interest in electric stackers. Furthermore, environmental considerations and regulations have contributed to the surge in demand for electric stackers in Europe. Electric stackers support the region's commitment to sustainability and reduced carbon emissions.

| Country | Germany |

|---|---|

| 2025 Value Share in Global Market | 8.4% |

| Country | United Kingdom |

|---|---|

| Value CAGR (2025 to 2035) | 6.4% |

Germany is known for its emphasis on precision engineering. This has led to the development of high-performance electric stackers. These stackers are integrated into complex manufacturing processes, contributing to the efficiency and precision of the Germany manufacturing sector. Their impact on the automotive sector in Germany is multifaceted and significant. High-performance electric stackers are employed by large automotive manufacturers in the country, such as Mercedes-Benz and BMW AG, to carry large metal sheets and heavy automotive parts.

As the United Kingdom focuses on sustainability and reducing carbon emissions, electric stackers have gained prominence due to their eco-friendly attributes. The geographical location of the United Kingdom, which serves as a gateway to Europe, underscores the importance of efficient logistics. Electric stackers contribute to optimizing supply chain operations.

The electric stacker industry in the Asia Pacific region is demonstrating notable dynamism and evolution. This sector's progress is underpinned by economic expansion, technological innovation, and a growing emphasis on operational efficiency across various industries.

| Country | Japan |

|---|---|

| 2025 Value Share in Global Market | 5.6% |

| Countries | Value CAGR (2025 to 2035) |

|---|---|

| China | 8.4% |

| India | 9.2% |

Space optimization is crucial in Japan due to the limited available land. Therefore, electric stackers have gained prominence in maximizing storage efficiency in dense urban areas. These stackers are often designed with compact dimensions and specialized maneuvering capabilities to utilize warehouse space efficiently.

China's rapid growth in e-commerce has led to an increased demand for electric stackers with a focus on cost-effectiveness. Manufacturers have capitalized on this demand by producing competitively priced electric stackers that cater to both large-scale warehouses and small e-commerce businesses. This affordability factor has contributed to the widespread adoption of electric stackers in China's logistics industry.

The electric stacker sector in India has grown significantly in recent years. Godrej Material Handling, an Indian firm, for example, introduced its brand-new Uno Electric Forklift truck in April 2024. This innovative design has received praise from customers for its outstanding functionality and dependability, and it is expected to help India become a leader in the electric forklift business.

| Segment | 2025 Value Share in Global Market |

|---|---|

| Lifting Equipment Application | 32.1% |

| 1500 kg Load Carrying Capacity | 34.3% |

Lifting equipment applications hold a prominent position in the electric stacker industry. As businesses strive to streamline their operations and enhance productivity, the demand for reliable and versatile lifting solutions has proliferated. Additionally, the versatility of electric stackers in lifting equipment applications plays a significant role in their dominance. Electric stackers are capable of handling a wide range of loads. This adaptability has further solidified their position as a leading choice for lifting equipment applications.

The 1500 kg load-carrying capacity exerts a significant influence over the market due to its commanding role in addressing the demands of diverse industries. This robust capacity caters to the burgeoning requirements of modern warehouses, manufacturing units, and distribution centers. In these industries, the need for efficient material handling is paramount. This capacity resonates particularly well with industries dealing with heavier products. It enables them to streamline their operations and optimize productivity.

Automated material handling solutions and other means to handle construction equipment requires fast and easy machines owing to the growth of the industrial infrastructure. Start-up companies are contributing to the growth of the electric stacker market share with advanced technologies and secondary features that significantly help with material handling.

New products are being introduced by the key market players operating in the industry, with advanced features to strengthen the product portfolio and capture a large water heater market share.

Key Market Players of the Electric Stacker Market:

Recent Developments in the Electric Stacker Market:

| Attribute | Details |

|---|---|

| Growth Rate | CAGR of 7.0% from 2025 to 2035 |

| Base year for estimation | 2025 |

| Historical data | 2020 to 2025 |

| Forecast period | 2025 to 2035 |

| Quantitative units | Revenue in USD Million and CAGR from 2025-2035 |

| Report coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

| Segments covered | Application, Load Carrying Capacity, Lifting Height, and Region. |

| Regional scope | North America; Latin America; Asia Pacific; MEA; Europe |

| Country scope | The USA, Canada, Brazil, Argentina, Germany, The United Kingdom, France, Spain, Italy, Nordics, BENELUX, Australia & New Zealand, China, India, GCC, South Africa |

| Key companies profiled | Jost’s Engineering Company Limited; Jungheinrich AG; Reliable Storage System; Gloline Equipment Pvt. Ltd.; Vestil Manufacturing Corporation; EP Equipment Co. Ltd.; CLARK Material Handling GmbH; CROWN Equipment Corporation; MAINI Materials Movement Pvt. Ltd.; Linde Material Handling GmbH; Presto Lifts; PROLIFT Handling Ltd.; Godrej Material Handling; KION Group AG; Mitsubishi Logisnext Co. Ltd.; Toyota Industries Corporation; Doosan Corporation; Boyce Manufacturing Company Limited; Hangcha Group Co. Ltd.; Hyster-Yale Materials Handling Inc., etc. |

| Customization | Available upon request. |

The global electric stacker market is estimated to be valued at USD 2.4 billion in 2025.

The market size for the electric stacker market is projected to reach USD 4.8 billion by 2035.

The electric stacker market is expected to grow at a 7.0% CAGR between 2025 and 2035.

The key product types in electric stacker market are lifting equipment, transporting loads, placing equipment and shifting equipment.

In terms of load carrying capacity, 1500 kg segment to command 34.7% share in the electric stacker market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Electric Vehicle Sensor Market Forecast and Outlook 2025 to 2035

Electric Vehicle Motor Market Forecast and Outlook 2025 to 2035

Electric Off-Road ATVs & UTVs Market Size and Share Forecast Outlook 2025 to 2035

Electric Blind Rivet Gun Market Size and Share Forecast Outlook 2025 to 2035

Electric Fireplace Market Size and Share Forecast Outlook 2025 to 2035

Electric Glider Market Size and Share Forecast Outlook 2025 to 2035

Electric Vehicle Battery Conditioners Market Size and Share Forecast Outlook 2025 to 2035

Electric Power Steering Motors Market Size and Share Forecast Outlook 2025 to 2035

Electric Motor Market Size and Share Forecast Outlook 2025 to 2035

Electric Gripper Market Size and Share Forecast Outlook 2025 to 2035

Electric Boat Market Size and Share Forecast Outlook 2025 to 2035

Electric Bicycle Market Size and Share Forecast Outlook 2025 to 2035

Electric Vehicle Transmission Market Size and Share Forecast Outlook 2025 to 2035

Electrical Enclosure Market Size and Share Forecast Outlook 2025 to 2035

Electrical Sub Panels Market Size and Share Forecast Outlook 2025 to 2035

Electric Cargo Bike Market Size and Share Forecast Outlook 2025 to 2035

Electrical Testing Services Market Size and Share Forecast Outlook 2025 to 2035

Electric Sub-meter Market Size and Share Forecast Outlook 2025 to 2035

Electric Light Commercial Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Electric Vehicle Fluid Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA