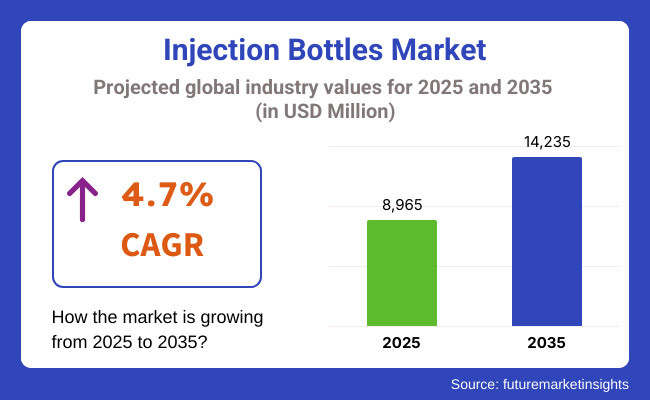

The injection bottles market will be experiencing unprecedented growth from 2025 to 2035 because of growing demand from the pharmaceutical, healthcare, and biotechnology industries. The market will increase from USD 8,965 million in 2025 to USD 14,235 million in 2035 at a compound annual growth rate (CAGR) of 4.7% over the forecast period.

There are several drivers of market growth. Of the major drivers, increasing need for safe and effective drug package solutions is more or less responsible for such demand. Injection bottles made mostly of glass and high-grade plastic-based material are the most important container of choice to hold biologic, vaccine, and injectable drug.

Increased biologics and biosimilars, most notably diabetes and oncology therapy, are influencing specialty injection bottles demand at large. But breakage problems with glass packs and contamination risk with their plastic equivalent are driving the industry to invest in state-of-the-art material science, designing the packaging that is strong without sacrificing the potency of the drug.

Various bottles used for injection, like Type I, Type II, and Type III glass bottles and polymer bottles, are used. Type I borosilicate glass type vials dominate the market due to their improved chemical resistance and ultra-high thermal resistance, best suited for sensitive biologics.

The polymeric form of vials like cyclic olefin polymers (COP) and cyclic olefin copolymers (COC) are favoured due to their lightness and non-fracturability, thus the most unique ones while dispensing in bulk form and while being dispensed in auto-injectors.

Aside from this, drug consumption, R&D laboratories, and animal testing constitute the biggest consumer group, and more and more pharmaceutical organizations using pre-sterilized ready-to-fill injectable vials to fill and store drugs with ease without exposing themselves constitute the biggest consumer group.

It is a premium injection bottle firm with huge value owing to highly quality bio-tech and pharma industries in America and Canada. Big shots like Pfizer, Moderna, and Johnson & Johnson have set up there, and hence there was enormous R&D on drug formulation, thus demanding strong packaging solutions. Strong demands by FDA rules demand high-quality injectable drug container materials, thus again propelling innovation in glass and polymer-based injection bottles.

The pandemic due to COVID-19 required vaccine storage innovation, with higher-barrier glass packaging becoming more in demand. Further investment in cell & gene therapies and target therapies has the North American market placing ultra-pure and contamination-free packaging as a way of responding to changing pharma needs.

Europe has an enormous market share with Germany, France, and the United Kingdom having advanced drug development. Germany also leads in drug development and bottle injection production with Bayer, Merck, and Boehringer Ingelheim.

Tight regulation of drug packaging by the European Medicines Agency (EMA) compels manufacturers to comply with safety materials and sterilization protocols. Green packaging is also the next big thing with the European manufacturers developing recyclable polymer-based injectable bottles, which are green and sterilized.

The growth market will witness the Asia-Pacific region growing the fastest, with Japanese, Chinese, Indian, and South Korean industries growing rapidly in the pharma industry. These two nations together are among the largest manufacturers of generic medicines as well as vaccines, and drug packaging on bulk amounts fill a prominent space in injection bottles.

Indian pharmaceutical companies such as Sun Pharma and Dr. Reddy's Laboratories are investing in high-quality borosilicate glass packaging in order to attain international export quality levels.

Higher government incentives to pharma production in India, like the Production Linked Incentive scheme, are compelling indigenous manufacturing of premium bottle injectors. However, the copycatting on a shoestring and supply chain inefficiencies characteristic to the region are compelling premium players to have their own inspection and regulatory clearance facilities.

Challenge: Contamination Risks and Regulatory Compliance

Bottle injection vials need to be of the highest sterility and chemical stability in order not to become contaminated. The most important issues are microbial contamination, particulate shedding, and extractable issues, particularly for biologics and vaccine injections.

Regulatory bodies such as the FDA, EMA, and Japan's PMDA have extremely strict packaging standards and hence manufacturers view compliance as time-consuming and costly. Other than this, glass supply is inhibited by borosilicate shortages and predictability of costs supply chain constraints and manufacturing capacity.

Opportunity: Biologics and Innovative Drug Delivery

With more and more biologics and biosimilars gaining dominance, injection bottle market has a humongous potential for growth. The drugs are costly and require innovative drug packaging and effective protection of the drug from contacting the pack material and drug stability.

Companies are now producing next-generation polymer injection bottles and glass of increased strength and lower extractable content, suitable for gene therapy, monoclonal antibodies, and mRNA vaccines. Pre-sterilized ready-to-use injection bottles are also gaining traction among pharma companies as they desire to make things easy and achieve tough compliance standards.

Between 2020 to 2024, the demand for the injection bottle market saw its all-time boom because of vaccine storage and biologic drug containment demand most globally as a result of the COVID-19 pandemic. It was also the time when there was a widespread trend towards the use of high-barrier material, pre-sterilized pack, and robotized filling lines. All of this was just to be more efficient without falling behind the increasingly tighter regulatory needs.

Looking ahead to 2025 and 2035, many of the leading driver trends will be at the helm of the market. The latest materials available in the market will be at center stage, with super-clean polymers and high-performance glass in the limelight. Green packaging will also spread further, with reusable polymer alternatives gaining more ground throughout the market in the industry. Pre-sterilized ready-to-fill containers will similarly gain traction due to the attempt to reduce the risk of contamination for high-risk drug uses.

Market Shifts: A Comparative Analysis 2020 to 2024 vs. 2025 to 2035

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Regulatory bodies emphasized rigorous quality standards for injection bottles in the name of patient safety. ISO standards became mandatory. |

| Technological Advancements | Manufacturers adopted automation of production lines for more efficiency and reduced human error. Incorporation of tamper-evident elements improved security. |

| Material Preferences | Glass remained as the most utilized material due to its inert qualities, though susceptible to shattering. Plastic alternatives like PET became prominent for its durability. |

| Environmental Sustainability | Early initiatives were launched in reducing carbon imprints, with some companies looking into using recyclable material. |

| Market Growth Drivers | The increase in chronic diseases and increased vaccination pressures led to higher demand for the injection bottles. The developing markets showed high growth due to advanced healthcare infrastructure. |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | Regulatory authorities further imposed stricter measures, focusing on sustainability and green considerations, to encourage the adoption of recyclable and green products. |

| Technological Advancements | Smart technology, such as RFID tags, was used to more effectively track and monitor injection bottles. Durability was improved and weight was reduced using advanced materials. |

| Material Preferences | It was a dramatic shift towards plastics of superior quality that ensued subsequent to the innovations addressing the previous leachability problems and made them more economical and safer. |

| Environmental Sustainability | The industry adopted green practice in large numbers, employing biodegradable packaging and recycling systems to promote global environmental goals. |

| Market Growth Drivers | Technological advancements in drug delivery and personalized medicine approaches required specialized inject bottles to drive market expansion. Population growth from an aging global population contributed to demand. |

United States injection bottle market is experiencing a consistent growth because of their wide application in pharmaceutical, cosmetic, and chemical industries. Inflation of use of plastic and glass injection bottles for aseptic packaging of medication is one of the major drivers of demand. Expansion of pharmaceutical industry, particularly in biologics and injectable medications, is further driving growth in the market.

Compliance with FDA-approved packaging is forcing firms to manufacture high-barrier, contamination-free injection bottles. Luxury packaging innovation in cosmetics is demanding injection bottles manufactured through glass that offers product sophistication and shelf presence. Additionally, the growing demand for environmentally friendly alternatives has driven biodegradable and recyclable polymer-based injection bottles that is in line with the growing base of eco-conscious consumers.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 4.6% |

United Kingdom UK injection bottle market is expanding due to increasing pharmaceutical exports and increasing need for advanced drug delivery devices. Stringent MHRA packaging standards are promoting the utilization of better quality, tamper evident injection bottles in medicinal uses.

UK personal care and cosmetic industry is also playing a major role in propelling the market growth with increasing demands for light-weight and customized injection bottles for skin and hair care products. Also, demand for polypropylene and PET-based injection bottles is increasing as companies wish to go green and cost-effective.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 4.8% |

European Union injection bottle market is driven by rigorous regulatory conditions such as EU GMP and REACH compliance, which are generating demand for superior inert packaging solutions. Germany, Italy, and France are leading the market due to their strong pharmaceutical production and advanced R&D in packaging technology.

The shift towards glass substitutes and bio-plastic injection bottles is picking up pace, particularly in Germany, where pharmaceutical sustainability projects are at the top of the agenda. The premium and recyclable packaging phenomenon of the cosmetics industry in the meantime continues to create new opportunities for growth across the country.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union | 4.3% |

Japan injection bottle market is fueled by cutting-edge pharma packaging technology and high levels of drug delivery excellence. Japan's position as a technologically advanced country has given rise to ultra-clean, anti-contaminated injection bottles utilized in specialty pharma and biologics.

Other than that, the nutraceutical industry is more stringent, and the injection bottles are being utilized for functional drinks and liquid dietary supplements. The trend is also moving towards the use of lightweight and shock-absorbing polymer injection bottles, especially for single-dose medical packaging.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 4.9% |

South Korean injection containers market is expanding as the vaccine and biopharmaceutical sectors are expanding rapidly. As the nation is developing as a center for offshored pharmaceutical manufacturing, demand for high-barrier, sterile injection containers is increasing, moving the market ahead.

Apart from that, market growth is also being propelled by demand from the cosmetics sector for airless and UV-resistant packaging. Smart packaging trends like QR-coded and tamper-evident injectable bottles are gaining traction, fulfilling the pharmaceutical and cosmetic product safety requirements.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 4.5% |

Glass injection vials hold the majority of the market share because they are more chemically resistant and inert, ensuring stability of delicate drug products. Borosilicate glass vials, for instance, show extensive use in injectable packaging of drugs, vaccines, and biologics because they do not support leaching of dangerous chemicals and drug potency. Glass vials are particularly of high significance when using biologic drugs and high-potency injectables requiring suitable storage conditions.

Growth in regulatory interest in the pharmaceutical stability and purity is a catalyst for demand in glass injection bottles. Stringent regulatory environments of established markets in North America and Europe by regulators such as the FDA and the EMA need injectable drug to be put into best-quality packaging, thus solidifying further the market hegemony of glass in this space. But cost and fragility over plastic are drawbacks when affordable alternatives are found in emerging economies.

As tough as glass, plastic injection bottles are now the choice, particularly for low-value and high-volume applications. Polypropylene (PP) and polyethylene terephthalate (PET) injection bottles are widely used due to their light weight, shock-resistance upon impact, and reduced manufacturing cost. That is why plastic injection bottles are the choice of preference in healthcare and clinical research applications where packaging and transportation time matters.

Among the most dominant trends is increasing the use of cyclic olefin copolymer (COP) and cyclic olefin polymer (COP) bottles, which are resistant to chemicals and more transparent than ordinary plastic bottles. Driven by advances in polymers technology and increasing demand for safe, non-reactive plastic bottles, the plastic industry will continue to grow unhampered, especially in the emerging pharma markets of India and Brazil.

The 50-100 ml segment is the industry leader in the market for injection bottles because it has wide applications in hospitals and pharmaceutical production. The range has wide application for vaccines, antibiotics, and intravenous drugs and hence is a must-have for regular medical practice. The COVID-19 pandemic also saw an unprecedented demand for vaccine vials and injectable drug packaging.

While this space of the aforementioned 100 ml is also becoming popular, especially in intravenous therapy and storage of bulk drugs, with growing parenteral nutrition and electrolyte solutions being demanded by hospitals, manufacturers are raising large-volume injection bottle production to meet expanding healthcare demands.

Hospitals constitute the biggest end-use application for injection bottles because of growing occurrences of chronic diseases and greater dependence on injectable drugs. Diabetes, cancer, and infectious diseases all have injectable treatments with large numbers of pack sizes, making them stable users of injection bottles in hospitals.

The same is also experiencing growing demand from clinical trial and drug production segments due to continuous biologics development and new injectable forms. Pharmaceutical firms increasingly want quality injection bottles that will guarantee drug stability, and this has encouraged the same to invest deeply in innovative packaging solutions.

The lab segment, both research institutes and diagnostic labs, is a major market for injection bottles, particularly for sample storage and analytical testing. As biotech research and vaccine development programs expand at a breakneck rate, this market will witness steady growth in the next few years.

Sustained regulatory interest in the integrity of pharmaceutical packaging and enhanced demand for biologic drugs is the overriding trend in the market for injection bottles. Sophisticated countries like Europe and North America strictly follow packaging material regulations, making the quality of high-performance glass and sophisticated plastic grades unmatched. The developing economies are, however, going through a shift toward cost-conformant but low-cost alternatives, offering scope for innovations in plastic injection bottle technology.

As the need for injectable drugs continues to rise globally, the market for injection bottles will continue to increase, with the growth maintained in hospital, drug manufacturing, and clinical trial application.

Injection bottles market is a fast-evolving competitive marketplace, where global and regional market players shape the growth of the market. Industry leaders enjoy prominent market positions based on product development, premium raw materials, and regulatory compliances, particularly for pharmaceutical and biotech markets.

The firms operate with focus areas in sustainability, high-performance polymers in formulating the resins, and sterile packaging. Market contains both established and new players with competing interests in forming market directions and product developments.

Market Share Analysis by Company

| Company Name | Estimated Market Share (%) |

|---|---|

| Gerresheimer AG | 14-18% |

| SCHOTT AG | 10-15% |

| Nipro Corporation | 8-12% |

| Bormioli Pharma | 6-10% |

| West Pharmaceutical Services, Inc. | 4-8% |

| Other Companies (combined) | 45-55% |

| Company Name | Key Offerings/Activities |

|---|---|

| Gerresheimer AG | Specializes in Type I, II, and III glass and polymer injection bottles for pharmaceuticals and biotech applications. Focuses on ultra-clean production facilities to meet stringent industry regulations. |

| SCHOTT AG | Offers borosilicate glass injection bottles designed for enhanced drug stability and compatibility. Invests in low-carbon manufacturing processes to align with sustainability goals. |

| Nipro Corporation | Produces multi-layer plastic injection bottles with superior barrier properties for sensitive drugs. Expanding its production capacity to support growing demand in emerging markets. |

| Bormioli Pharma | Manufactures Type I molded and tubular glass bottles, catering to injectables and vaccines. Prioritizes eco-friendly materials and lightweight packaging solutions. |

| West Pharmaceutical Services, Inc. | Supplies sterile-ready injection bottles with advanced elastomeric closures for enhanced drug protection. Focuses on single-use packaging innovations for biotech companies. |

Key Company Insights

Gerresheimer AG (14-18%)

Gerresheimer AG is a leader in the injectable bottle market, providing pharmaceutical-grade glass and plastic packaging solutions for injectable drugs. It has highly advanced manufacturing facilities meeting strict pharmaceutical safety standards, especially for injectables. Gerresheimer is strengthening its position in the packaging of biologics, with clean-room-free contamination and high-barrier solutions for sensitive drugs.

SCHOTT AG (10-15%)

SCHOTT AG is an expert in the production of borosilicate glass injection vials, which are a preferred pharmaceutical company partner for its drug interaction low, high chemical resistance nature. SCHOTT has combined green production methodologies to minimize the carbon footprint within its glassmaking process. SCHOTT's regional production centers located in Asia and Europe enhance the supply chain, which is catering to the increase in demand for high-purity injection packaging.

Nipro Corporation (8-12%)

Nipro Corporation has established a solid presence in the business of injection bottles through its innovative multi-layer plastic bottles that increase the stability of drugs. It is going to increase production capacity in Asia and Latin America to cater to local pharmaceutical companies. Nipro's investment in high-barrier polymer technology has made it a trusted vendor of biologics and specialty injectables.

Bormioli Pharma (6-10%)

Bormioli Pharma is a prominent manufacturer of tubular and molded glass injection vials, providing critical packaging for injectables, vaccines, and antibiotics. The company has gone green by creating lightweight glass packaging that minimizes material waste while remaining strong. Bormioli Pharma also works with biotech companies to create special injection vials for the future generation of biologics.

West Pharmaceutical Services, Inc. (4-8%)

West Pharmaceutical Services' brand is built on sterile-ready injectable bottles with state-of-the-art elastomeric closures that provide ultimate drug protection against contamination and oxidation. West's R&D emphasis has enabled it to introduce single-use packaging solutions, which are being widely adopted in the biotechnology industry. West's worldwide distribution network guarantees prompt availability to pharmaceutical manufacturers across the globe.

Other Key Players (45-55% Combined)

Various other companies play major roles in the injection bottle industry by triggering innovation, maintaining effective supply chains, and financing sustainability initiatives. These include:

The overall market size for the injection bottles market was USD 8,965 million in 2025.

The injection bottles market is expected to reach USD 14,235 million in 2035.

The growing demand for pharmaceutical packaging, increasing adoption of plastic and glass injection bottles, and rising investments in the healthcare sector fuel the injection bottles market during the forecast period.

The top 5 countries driving the development of the injection bottles market are the USA, Germany, China, India, and Japan.

On the basis of material, plastic injection bottles are expected to command a significant share over the forecast period.

Table 1: Global Market Value (US$ Million) Forecast by Region, 2018 to 2033

Table 2: Global Market Volume (Units) Forecast by Region, 2018 to 2033

Table 3: Global Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 4: Global Market Volume (Units) Forecast by Material, 2018 to 2033

Table 5: Global Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 6: Global Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 7: Global Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 8: Global Market Volume (Units) Forecast by End-users, 2018 to 2033

Table 9: North America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 10: North America Market Volume (Units) Forecast by Country, 2018 to 2033

Table 11: North America Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 12: North America Market Volume (Units) Forecast by Material, 2018 to 2033

Table 13: North America Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 14: North America Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 15: North America Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 16: North America Market Volume (Units) Forecast by End-users, 2018 to 2033

Table 17: Latin America Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 18: Latin America Market Volume (Units) Forecast by Country, 2018 to 2033

Table 19: Latin America Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 20: Latin America Market Volume (Units) Forecast by Material, 2018 to 2033

Table 21: Latin America Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 22: Latin America Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 23: Latin America Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 24: Latin America Market Volume (Units) Forecast by End-users, 2018 to 2033

Table 25: Western Europe Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 26: Western Europe Market Volume (Units) Forecast by Country, 2018 to 2033

Table 27: Western Europe Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 28: Western Europe Market Volume (Units) Forecast by Material, 2018 to 2033

Table 29: Western Europe Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 30: Western Europe Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 31: Western Europe Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 32: Western Europe Market Volume (Units) Forecast by End-users, 2018 to 2033

Table 33: Eastern Europe Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 34: Eastern Europe Market Volume (Units) Forecast by Country, 2018 to 2033

Table 35: Eastern Europe Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 36: Eastern Europe Market Volume (Units) Forecast by Material, 2018 to 2033

Table 37: Eastern Europe Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 38: Eastern Europe Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 39: Eastern Europe Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 40: Eastern Europe Market Volume (Units) Forecast by End-users, 2018 to 2033

Table 41: South Asia and Pacific Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 42: South Asia and Pacific Market Volume (Units) Forecast by Country, 2018 to 2033

Table 43: South Asia and Pacific Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 44: South Asia and Pacific Market Volume (Units) Forecast by Material, 2018 to 2033

Table 45: South Asia and Pacific Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 46: South Asia and Pacific Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 47: South Asia and Pacific Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 48: South Asia and Pacific Market Volume (Units) Forecast by End-users, 2018 to 2033

Table 49: East Asia Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 50: East Asia Market Volume (Units) Forecast by Country, 2018 to 2033

Table 51: East Asia Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 52: East Asia Market Volume (Units) Forecast by Material, 2018 to 2033

Table 53: East Asia Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 54: East Asia Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 55: East Asia Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 56: East Asia Market Volume (Units) Forecast by End-users, 2018 to 2033

Table 57: Middle East and Africa Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 58: Middle East and Africa Market Volume (Units) Forecast by Country, 2018 to 2033

Table 59: Middle East and Africa Market Value (US$ Million) Forecast by Material, 2018 to 2033

Table 60: Middle East and Africa Market Volume (Units) Forecast by Material, 2018 to 2033

Table 61: Middle East and Africa Market Value (US$ Million) Forecast by Capacity, 2018 to 2033

Table 62: Middle East and Africa Market Volume (Units) Forecast by Capacity, 2018 to 2033

Table 63: Middle East and Africa Market Value (US$ Million) Forecast by End-users, 2018 to 2033

Table 64: Middle East and Africa Market Volume (Units) Forecast by End-users, 2018 to 2033

Figure 1: Global Market Value (US$ Million) by Material, 2023 to 2033

Figure 2: Global Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 3: Global Market Value (US$ Million) by End-users, 2023 to 2033

Figure 4: Global Market Value (US$ Million) by Region, 2023 to 2033

Figure 5: Global Market Value (US$ Million) Analysis by Region, 2018 to 2033

Figure 6: Global Market Volume (Units) Analysis by Region, 2018 to 2033

Figure 7: Global Market Value Share (%) and BPS Analysis by Region, 2023 to 2033

Figure 8: Global Market Y-o-Y Growth (%) Projections by Region, 2023 to 2033

Figure 9: Global Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 10: Global Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 11: Global Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 12: Global Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 13: Global Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 14: Global Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 15: Global Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 16: Global Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 17: Global Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 18: Global Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 19: Global Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 20: Global Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 21: Global Market Attractiveness by Material, 2023 to 2033

Figure 22: Global Market Attractiveness by Capacity, 2023 to 2033

Figure 23: Global Market Attractiveness by End-users, 2023 to 2033

Figure 24: Global Market Attractiveness by Region, 2023 to 2033

Figure 25: North America Market Value (US$ Million) by Material, 2023 to 2033

Figure 26: North America Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 27: North America Market Value (US$ Million) by End-users, 2023 to 2033

Figure 28: North America Market Value (US$ Million) by Country, 2023 to 2033

Figure 29: North America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 30: North America Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 31: North America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 32: North America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 33: North America Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 34: North America Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 35: North America Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 36: North America Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 37: North America Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 38: North America Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 39: North America Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 40: North America Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 41: North America Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 42: North America Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 43: North America Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 44: North America Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 45: North America Market Attractiveness by Material, 2023 to 2033

Figure 46: North America Market Attractiveness by Capacity, 2023 to 2033

Figure 47: North America Market Attractiveness by End-users, 2023 to 2033

Figure 48: North America Market Attractiveness by Country, 2023 to 2033

Figure 49: Latin America Market Value (US$ Million) by Material, 2023 to 2033

Figure 50: Latin America Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 51: Latin America Market Value (US$ Million) by End-users, 2023 to 2033

Figure 52: Latin America Market Value (US$ Million) by Country, 2023 to 2033

Figure 53: Latin America Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 54: Latin America Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 55: Latin America Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 56: Latin America Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 57: Latin America Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 58: Latin America Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 59: Latin America Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 60: Latin America Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 61: Latin America Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 62: Latin America Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 63: Latin America Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 64: Latin America Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 65: Latin America Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 66: Latin America Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 67: Latin America Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 68: Latin America Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 69: Latin America Market Attractiveness by Material, 2023 to 2033

Figure 70: Latin America Market Attractiveness by Capacity, 2023 to 2033

Figure 71: Latin America Market Attractiveness by End-users, 2023 to 2033

Figure 72: Latin America Market Attractiveness by Country, 2023 to 2033

Figure 73: Western Europe Market Value (US$ Million) by Material, 2023 to 2033

Figure 74: Western Europe Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 75: Western Europe Market Value (US$ Million) by End-users, 2023 to 2033

Figure 76: Western Europe Market Value (US$ Million) by Country, 2023 to 2033

Figure 77: Western Europe Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 78: Western Europe Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 79: Western Europe Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 80: Western Europe Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 81: Western Europe Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 82: Western Europe Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 83: Western Europe Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 84: Western Europe Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 85: Western Europe Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 86: Western Europe Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 87: Western Europe Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 88: Western Europe Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 89: Western Europe Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 90: Western Europe Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 91: Western Europe Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 92: Western Europe Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 93: Western Europe Market Attractiveness by Material, 2023 to 2033

Figure 94: Western Europe Market Attractiveness by Capacity, 2023 to 2033

Figure 95: Western Europe Market Attractiveness by End-users, 2023 to 2033

Figure 96: Western Europe Market Attractiveness by Country, 2023 to 2033

Figure 97: Eastern Europe Market Value (US$ Million) by Material, 2023 to 2033

Figure 98: Eastern Europe Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 99: Eastern Europe Market Value (US$ Million) by End-users, 2023 to 2033

Figure 100: Eastern Europe Market Value (US$ Million) by Country, 2023 to 2033

Figure 101: Eastern Europe Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 102: Eastern Europe Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 103: Eastern Europe Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 104: Eastern Europe Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 105: Eastern Europe Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 106: Eastern Europe Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 107: Eastern Europe Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 108: Eastern Europe Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 109: Eastern Europe Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 110: Eastern Europe Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 111: Eastern Europe Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 112: Eastern Europe Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 113: Eastern Europe Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 114: Eastern Europe Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 115: Eastern Europe Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 116: Eastern Europe Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 117: Eastern Europe Market Attractiveness by Material, 2023 to 2033

Figure 118: Eastern Europe Market Attractiveness by Capacity, 2023 to 2033

Figure 119: Eastern Europe Market Attractiveness by End-users, 2023 to 2033

Figure 120: Eastern Europe Market Attractiveness by Country, 2023 to 2033

Figure 121: South Asia and Pacific Market Value (US$ Million) by Material, 2023 to 2033

Figure 122: South Asia and Pacific Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 123: South Asia and Pacific Market Value (US$ Million) by End-users, 2023 to 2033

Figure 124: South Asia and Pacific Market Value (US$ Million) by Country, 2023 to 2033

Figure 125: South Asia and Pacific Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 126: South Asia and Pacific Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 127: South Asia and Pacific Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 128: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 129: South Asia and Pacific Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 130: South Asia and Pacific Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 131: South Asia and Pacific Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 132: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 133: South Asia and Pacific Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 134: South Asia and Pacific Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 135: South Asia and Pacific Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 136: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 137: South Asia and Pacific Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 138: South Asia and Pacific Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 139: South Asia and Pacific Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 140: South Asia and Pacific Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 141: South Asia and Pacific Market Attractiveness by Material, 2023 to 2033

Figure 142: South Asia and Pacific Market Attractiveness by Capacity, 2023 to 2033

Figure 143: South Asia and Pacific Market Attractiveness by End-users, 2023 to 2033

Figure 144: South Asia and Pacific Market Attractiveness by Country, 2023 to 2033

Figure 145: East Asia Market Value (US$ Million) by Material, 2023 to 2033

Figure 146: East Asia Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 147: East Asia Market Value (US$ Million) by End-users, 2023 to 2033

Figure 148: East Asia Market Value (US$ Million) by Country, 2023 to 2033

Figure 149: East Asia Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 150: East Asia Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 151: East Asia Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 152: East Asia Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 153: East Asia Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 154: East Asia Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 155: East Asia Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 156: East Asia Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 157: East Asia Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 158: East Asia Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 159: East Asia Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 160: East Asia Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 161: East Asia Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 162: East Asia Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 163: East Asia Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 164: East Asia Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 165: East Asia Market Attractiveness by Material, 2023 to 2033

Figure 166: East Asia Market Attractiveness by Capacity, 2023 to 2033

Figure 167: East Asia Market Attractiveness by End-users, 2023 to 2033

Figure 168: East Asia Market Attractiveness by Country, 2023 to 2033

Figure 169: Middle East and Africa Market Value (US$ Million) by Material, 2023 to 2033

Figure 170: Middle East and Africa Market Value (US$ Million) by Capacity, 2023 to 2033

Figure 171: Middle East and Africa Market Value (US$ Million) by End-users, 2023 to 2033

Figure 172: Middle East and Africa Market Value (US$ Million) by Country, 2023 to 2033

Figure 173: Middle East and Africa Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 174: Middle East and Africa Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 175: Middle East and Africa Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 176: Middle East and Africa Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 177: Middle East and Africa Market Value (US$ Million) Analysis by Material, 2018 to 2033

Figure 178: Middle East and Africa Market Volume (Units) Analysis by Material, 2018 to 2033

Figure 179: Middle East and Africa Market Value Share (%) and BPS Analysis by Material, 2023 to 2033

Figure 180: Middle East and Africa Market Y-o-Y Growth (%) Projections by Material, 2023 to 2033

Figure 181: Middle East and Africa Market Value (US$ Million) Analysis by Capacity, 2018 to 2033

Figure 182: Middle East and Africa Market Volume (Units) Analysis by Capacity, 2018 to 2033

Figure 183: Middle East and Africa Market Value Share (%) and BPS Analysis by Capacity, 2023 to 2033

Figure 184: Middle East and Africa Market Y-o-Y Growth (%) Projections by Capacity, 2023 to 2033

Figure 185: Middle East and Africa Market Value (US$ Million) Analysis by End-users, 2018 to 2033

Figure 186: Middle East and Africa Market Volume (Units) Analysis by End-users, 2018 to 2033

Figure 187: Middle East and Africa Market Value Share (%) and BPS Analysis by End-users, 2023 to 2033

Figure 188: Middle East and Africa Market Y-o-Y Growth (%) Projections by End-users, 2023 to 2033

Figure 189: Middle East and Africa Market Attractiveness by Material, 2023 to 2033

Figure 190: Middle East and Africa Market Attractiveness by Capacity, 2023 to 2033

Figure 191: Middle East and Africa Market Attractiveness by End-users, 2023 to 2033

Figure 192: Middle East and Africa Market Attractiveness by Country, 2023 to 2033

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Injection Epoxy Chemical Anchors Market Size and Share Forecast Outlook 2025 to 2035

Injection Blow Molding Machine Market Size and Share Forecast Outlook 2025 to 2035

Injection Molding Machine Market Size and Share Forecast Outlook 2025 to 2035

Injection Moulding Cosmetic Packaging Market Size and Share Forecast Outlook 2025 to 2035

Injection Molding Machines Industry Analysis in India Size, Share & Forecast 2025 to 2035

Injection Pen Market Insights - Growth, Demand & Forecast 2025 to 2035

Market Share Distribution Among Injection Moulding Cosmetic Packaging Manufacturers

Injection Molded Plastic Market Trends – Growth & Forecast 2024-2034

Injection Molding Polyamide 6 Market Growth – Trends & Forecast 2024-2034

Injection Molding Containers Market

Lip Injection Market Size and Share Forecast Outlook 2025 to 2035

Fuel Injection System Market Growth - Trends & Forecast 2025 to 2035

Micro Injection Molded Plastic Market Size and Share Forecast Outlook 2025 to 2035

Metal Injection Molding (MIM) Parts Market Size and Share Forecast Outlook 2025 to 2035

India Injection Moulders Market – Demand and Growth Forecast 2025 to 2035

Europe Injection Molding Machines Market Size and Share Forecast Outlook 2025 to 2035

Europe Injection Moulders Market Size and Share Forecast Outlook 2025 to 2035

Powder Injection Molding Market Growth – Trends & Forecast 2025 to 2035

Sliding Injection Molding Machines Market Size and Share Forecast Outlook 2025 to 2035

Plastic Injection Molding Machine For Medtech Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA